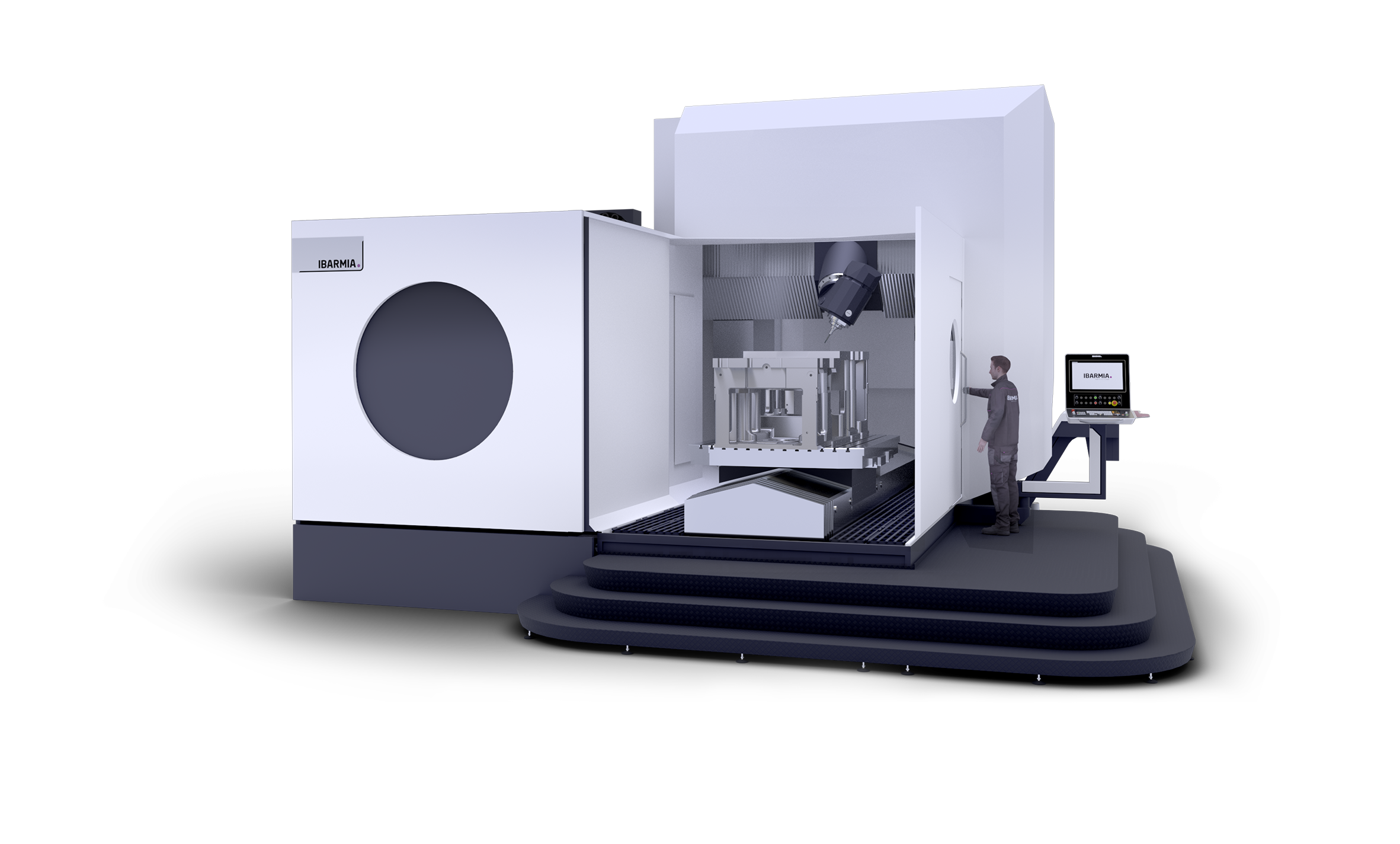

P SERIES

P EXTREME

36 / 30 / 26

High performance portal structure 5 axis universal machining centers

5 Axis

MANUFACTURING TECHNOLOGY

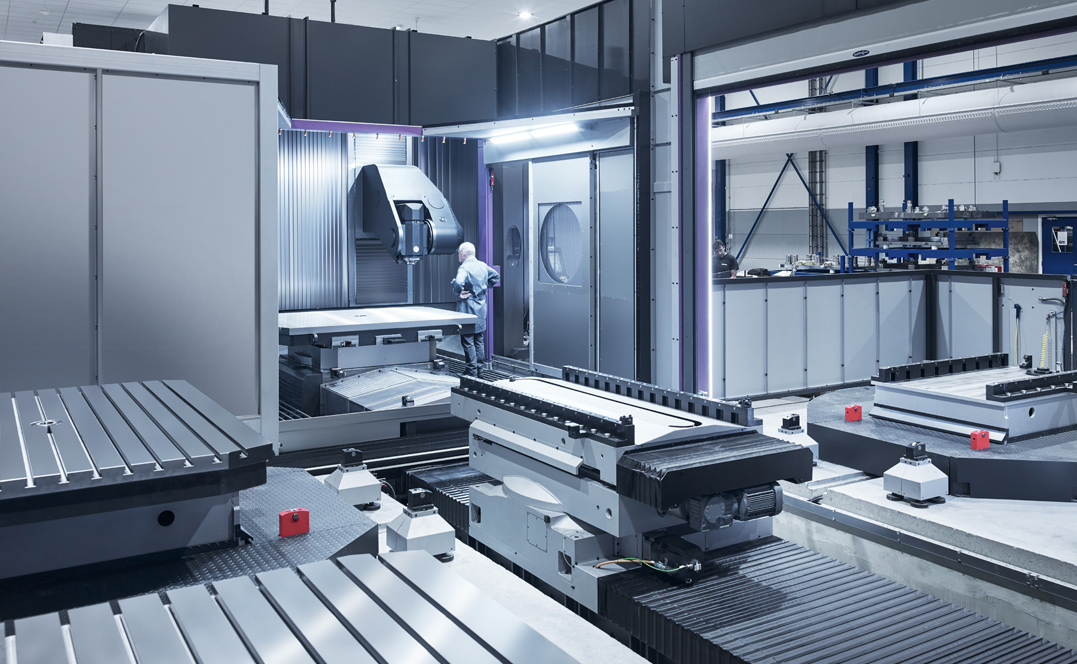

Power, accuracy and dynamics combined with excellent chip evacuation, ergonomics and intelligent production functions.

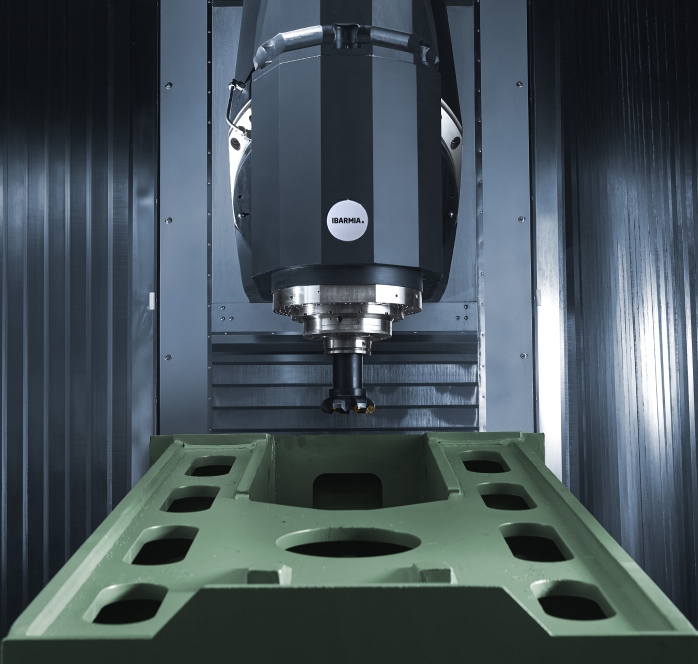

Spindle tapers

SK-50 • BT-50 • HSK 100 • CAPTO C8

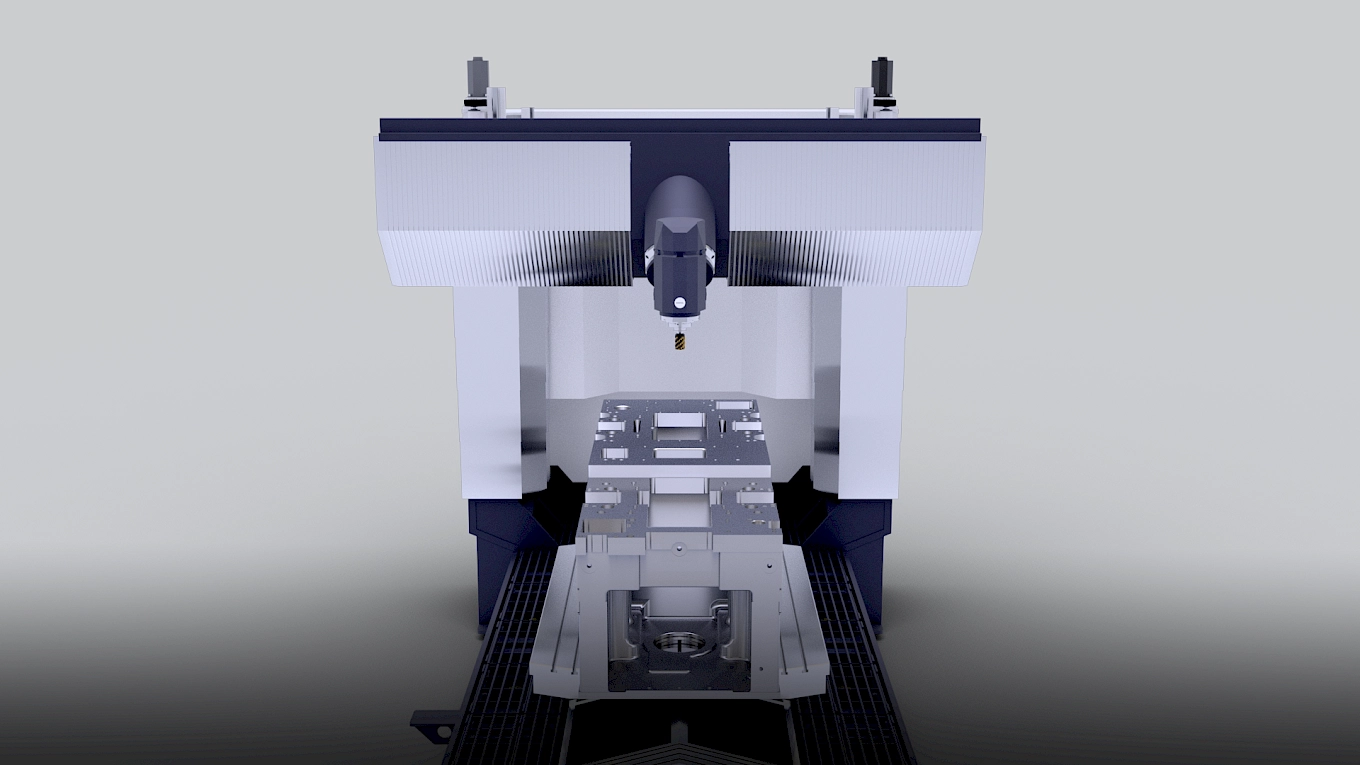

Axis travels

X • From 2600 to 3600 mm / Y • From 2500 to 3300 mm

Z • From 1500 to 1900 mm

B • -15º/+195º / A • -45º/+135º

Spindle

Up to 84 kW - 12.000 rpm

Spindle heads

Two available models:

THC / THR

Continuous tilting heads with torque motor and

direct measuring systems in the axes.

THC_ B axis head

Maintain the same tool center point across the full range

-15º/+195º

THR_ A axis head

Fork type spindle head ideal for negative angles

-45º/+135º

Models

Capacity by size

Table size

1.600 x 1.600 mm

Maximum load capacity

25.000 Kg

Table size

1250 x 1600 mm

Maximum load capacity

20.000 Kg

Table size

1250 x 1250 mm

Maximum load capacity

15.000 Kg

Industries

AEROSPACE

AUTOMOTIVE

OIL & GAS

FERROCARRIL

VALVES & PUMPS

MOLDS & DIE

MACHINERY

ENERGY

CRANES

Leave us your data to download the catalog

REQUEST QUOTATION

Contact with IBARMIA for further information

Contact us

No-obligation inquiry

No-obligation inquiry