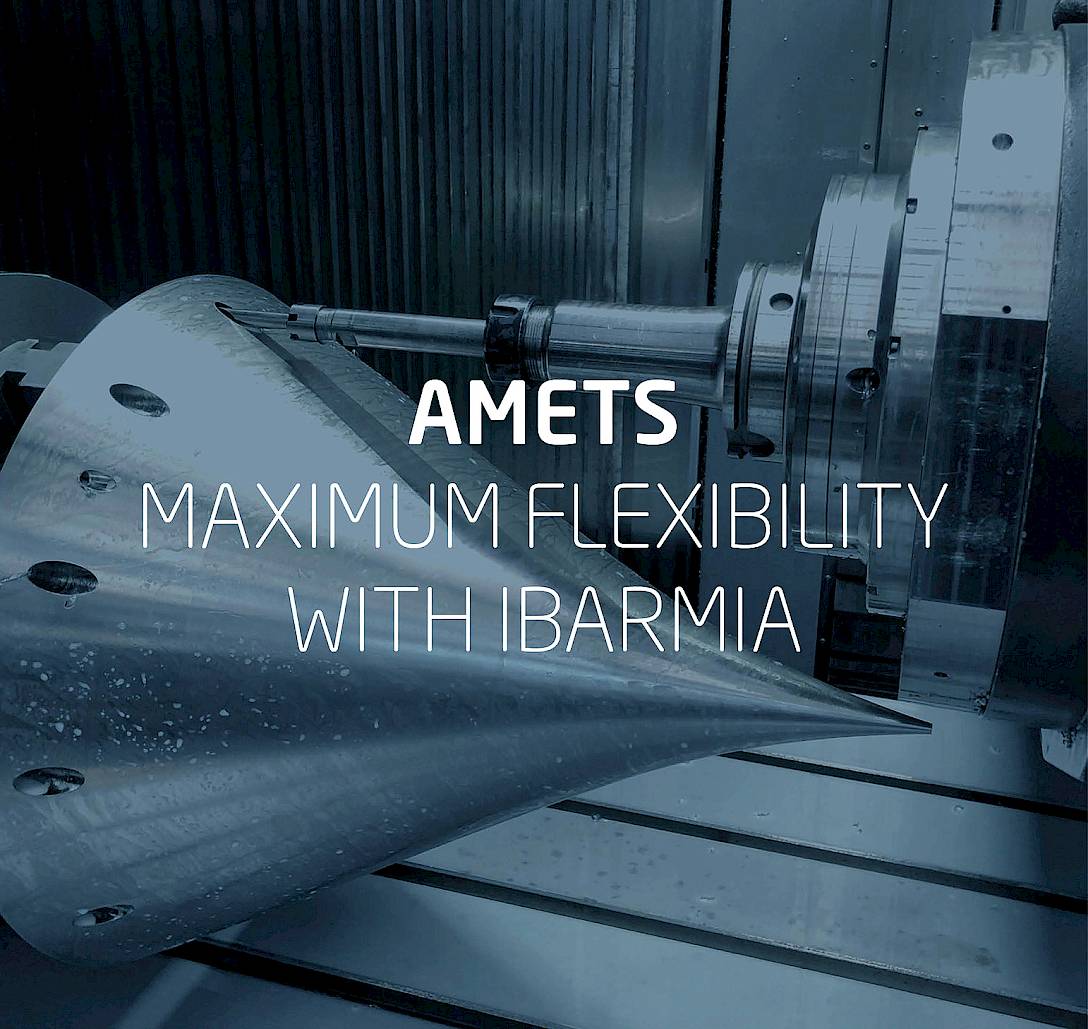

Situated in the heart of Europe's most dynamic manufacturing corridor, Scherrer Fertigungstechnik in Feldkirch, Austria, is strategically located at the confluence of Austria, Germany, Switzerland, and Liechtenstein. At its 1000sq/m facility, the manufacturer of industrial machinery has recently installed a large bed IBARMIA ZMS5_30.08 EXTREME STAR EDITION machining centre to enhance flexibility and productivity.

Success cases

Scherrer CNC: Technology, Vision and Flexibility with IBARMIA’s New GEN6 Platform

Located in Feldkirch, at the industrial crossroads of Austria, Germany, Switzerland, and Liechtenstein, Scherrer Fertigungstechnik represents a new generation of high-precision machine shops: lean, agile, and technology-driven. With a small team of just five skilled professionals, the company has established itself as a trusted machining partner across multiple industries.

In line with its strategy of continuous technological renewal, Scherrer became the first customer to adopt IBARMIA’s new generation travelling column machining centre, installing a fully customised IBARMIA ZMS5_30.08 EXTREME STAR EDITION. This milestone marks not only a leap forward in capability but also a shared commitment to pushing technological boundaries.

“We invest in a new machine every two or three years. It always has to be the latest technology — not outdated solutions,” says company owner Norbert Scherrer.

Unlike many businesses that wait for production bottlenecks to force an upgrade, Scherrer takes a proactive approach to investment. The decision to choose the IBARMIA ZMS5_30.08 EXTREME STAR EDITION machine was driven by the increasing variety and complexity of their production mix, which required a solution that could offer both high-end performance and extreme flexibility.

With 3,000 mm travel on the X-axis, an extended tilting head with internal high-pressure coolant, and a rotary table of 800 mm, the GEN6 machine enables full five-sided machining in a single setup — dramatically reducing handling time, error risk and cycle duration. But one of the most significant game-changers is the 224-position static Indunorm tool magazine, tailored to support multi-material, multi-job workflows without tool changeovers between batches.

“Having that many tools available means we can switch instantly from one job to the next. It keeps us fast, flexible, and ahead of deadlines,” Scherrer explains.

The new Heidenhain TNC7 control system enhances usability, offering a touchscreen interface, improved visualisation, and a rotatable panel for better operator ergonomics. These features contribute to faster setups and more efficient programming, especially valuable in a workshop where every team member handles multiple roles — from CAM programming to machining and quality inspection.

Thermal stability was also a key factor in the selection process. The IBARMIA ZMS5_30.08 EXTREME STAR EDITION machine is equipped with Schneeberger guideways and integrated compensation systems to maintain micron-level accuracy, even under varying workshop conditions.

“We keep the shop between 19 and 23 °C, but the machine’s structure and compensation system are what guarantee consistent precision — no matter the season,” adds Scherrer.

Operational results have already confirmed the impact of the investment: faster turnaround times, higher part quality, and greater agility in handling demanding or large-format workpieces. The 5-axis configuration, reinforced structure, and built-in automation features make the machine not just an upgrade — but a platform for growth.

Beyond the hardware, the collaboration with IBARMIA has been a key success factor. From the early design stages to final commissioning and technical support, Scherrer highlights the added value of working with a responsive and knowledgeable team.

“Support from both Spain and the local team in Austria has been excellent. If we had more space, we’d already be planning our next, bigger IBARMIA,” he concludes with a smile.