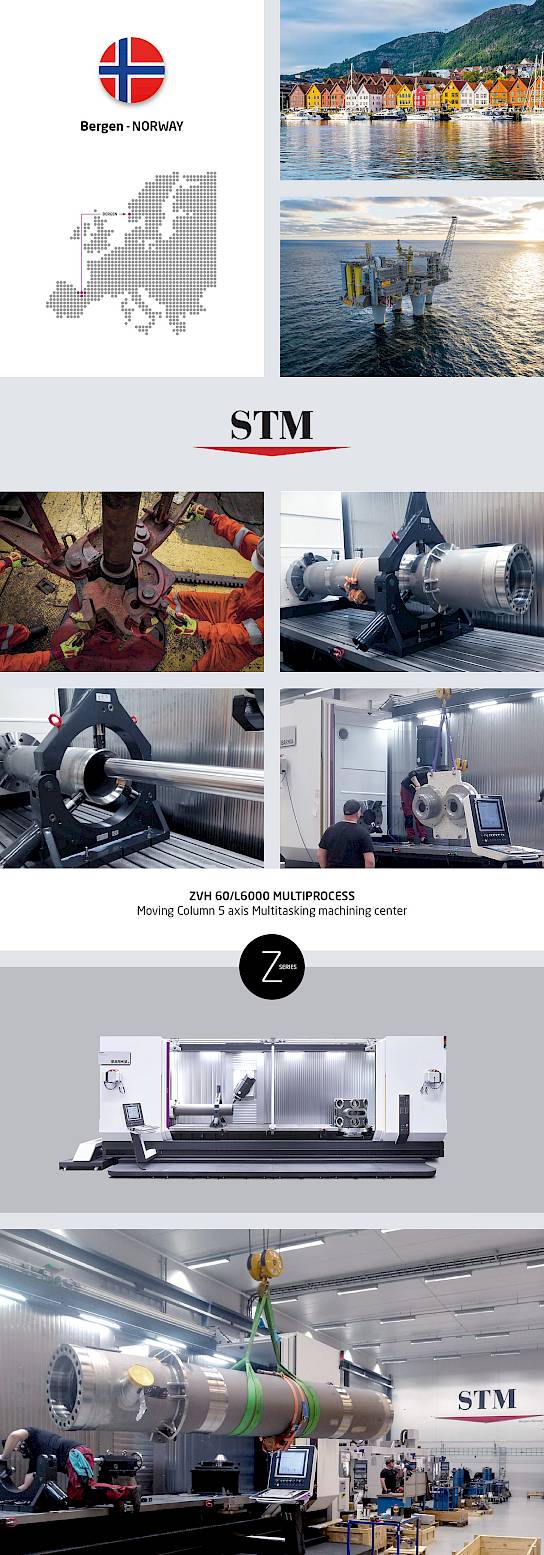

The Norwegian company STM relies on IBARMIA's advanced technology to meet the demanding requirements of the Oil & Gas sector, with the collaboration of our distributor KASPO.

Success cases

STM CHOOSES THE ZVH60 MULTIPROCESS TO BOOST ITS PRODUCTION IN THE OIL & GAS SECTOR

STM, a company specializing in the manufacturing of components for the Oil & Gas sector and based in Bergen (Norway), has incorporated into its plant a ZVH 60/L6000 MULTIPROCESS, a machine configured with numerous special options that responds to its need for flexibility, power, and precision.

A CUSTOM CONFIGURATION FOR HIGH-LEVEL PRODUCTION

The model acquired by STM features exceptional technical specifications, including:

- Z-axis of 1300 mm

- Integrated rotary table of Ø1200 mm (500 rpm, maximum load of 6000 kg)

- Horizontal table of Ø630 mm (up to 1800 rpm)

- Two long boring bars Sandvik Silent Tool (Ø80 x 1200 mm and Ø120 x 1900 mm)

- MADAULA angle head in the tool magazine

- KOMET U-axis head with 70 mm stroke, essential for machining BX-type grooves

- Internal cooling at 70 bar, double air filtration, and 80 CAPTO C8 tools

- Renishaw RMP60 and APCS-45 probe systems

- Various manual and hydraulic ATLING supports to stabilize long parts

- NSM software and hardware for pendulum machining

- Heidenhain KinematicsOpt function for precise head calibration

This combination makes the ZVH 60 a truly flexible machining solution, capable of handling everything from horizontal and vertical turning to complex milling and operations with special heads.

PROVEN PERFORMANCE AND STABILITY

One of the major milestones in this project has been the use of long boring bars with demanding materials such as stainless steel 316L.

According to STM, the result has been "exceptional cutting stability and a perfect surface finish."

Additionally, programming with Edge Cam and customized post-processors has allowed full utilization of the machine's potential, including simultaneous turning and milling on A and C axes.

A STRONG RELATIONSHIP IN THE NORWEGIAN MARKET

This new success story has been possible thanks to the collaboration with KASPO, our distributor in Norway since 2012. Their knowledge of the local market and technical support have been key to establishing IBARMIA as a benchmark in the sector.

With this delivery, there are already more than 15 IBARMIA machines installed in Norway, many of them in critical applications for Oil & Gas. STM, founded in 2006 and with a turnover of more than 2.3 million euros, thus joins a customer base that trusts in IBARMIA's high value-added technology to continue growing in demanding environments.