By installing an IBARMIA THC 16 Extreme machining centre, ANDRITZ Knife Systems has transformed its production—replacing three legacy machines with one highly precise, efficient, and fully automated 5-axis solution.

Success cases

ANDRITZ Knife Systems Takes a Leap in Precision with the IBARMIA THC 16 Extreme

A Solution to a Critical Challenge

At its manufacturing site in Sweden, ANDRITZ Knife Systems, a key supplier of knife systems and mechanical components for the forest industry, faced a significant production challenge: replace three outdated machining centres that were limiting productivity and precision.

The goal was not just to replace the old machines, but to consolidate production into a single system that could deliver higher precision, shorter setup times, and fully unattended operation.

“We needed a technical step forward – and IBARMIA delivered exactly that.”

— Magnus Flemström, Production Technician at ANDRITZ

The Ideal Machine, Tailored to the Task

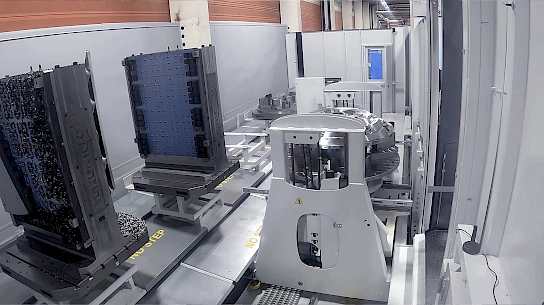

After a detailed evaluation with their long-term partner Stenbergs, ANDRITZ selected the IBARMIA THC 16 Extreme, a 5-axis simultaneous machining centre that not only met, but exceeded their expectations.

The machine was customized with:

- Extended column for large components

- FASTEMS automation system for 24/7 production

- 6000 kg load capacity and full multi-side machining

- 84kW, 12,000 rpm electrospindle ideal for hardened tool steel

“The IBARMIA THC 16 Extreme was more or less the perfect solution for us.”

— Magnus Flemström, ANDRITZ

Real Impact on Production

The results were immediate and significant:

- Cycle times dramatically reduced

- Setup time slashed thanks to multi-axis machining and new fixturing

- Part quality improved, with tolerances now within a few microns

- Safer, more ergonomic workflow for operators

“We now produce our parts to tolerances of just a few microns — something that wasn’t possible with our old machines.”

— Magnus Flemström, ANDRITZ

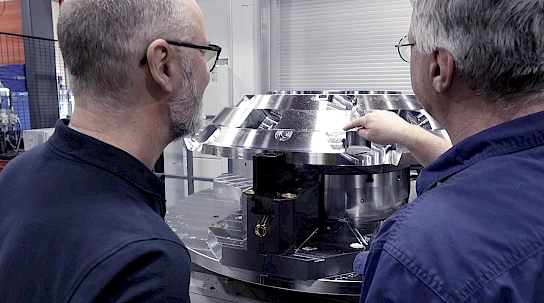

A Smooth and Transparent Partnership

From the early phases of the project, ANDRITZ worked closely with IBARMIA and Stenbergs to define the technical scope and ensure a seamless installation.

Future-Ready Manufacturing

With this strategic investment, ANDRITZ has not only improved its production capacity, but also strengthened its commitment to high-precision, sustainable solutions for the global forest industry. The combination of advanced technology, automation, and collaboration has made this project a true benchmark in their sector.