With more than 40 years of experience in the design and manufacture of rubber, thermoplastic and bimaterial injection molds for the automotive sector, MAYMO reinforces its machining capacity in Cáceres with a 5-axis IBARMIA ZVH 48/L2200 EXTREME moving column center with integrated rotary table.

Success cases

MAYMO reinforces its production of injection molds with an IBARMIA ZVH 48/L2200 EXTREME

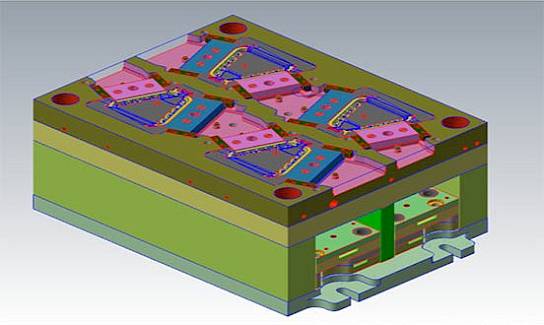

INDUSTRIAS EXTREMEÑAS DE MATRICES Y MOLDES MAYMO is a family enterprise located in Cáceres (Spain) with more than 40 years of experience in the design and manufacture of rubber, thermoplastic and bimaterial injection molds, mainly for the automotive sector.

To continue to meet the precision, surface quality and delivery time requirements of this market, the company has added to its machine park an IBARMIA ZVH 48/L2200 EXTREME machining center, a 5-axis moving column solution with integrated rotary table.

The customer: specialist in rubber, thermoplastic and bimaterial molds

MAYMO designs and manufactures injection molds for rubber, thermoplastics and bi-material parts, covering the whole cycle: from the technical office to the adjustment, assembly and associated machining.

The company has specific resources for:

- Design and technical office, with CAD/CAM software dedicated to molds.

- Machining of complex components.

- Adjustment and assembly of dies and molds ready for mass production.

The challenge: complex molds, demanding tolerances

In the automotive die and mold sector, manufacturers are faced with:

- Complex geometries and multiple cavities.

- Very high demands on precision and surface finish.

- Demanding materials, including stainless steels and special alloys.

- Tight lead times and the need for rapid design changes.

To meet these demands, it is key to have machining centers capable of combining:

- High fixed-table loading capacity for mold bases and mold plates.

- 5-axis machining for inclined bores, 3D shapes and critical details.

- Flexibility for short series, mold modifications and new references.

The solution: IBARMIA ZVH 48/L2200 EXTREME

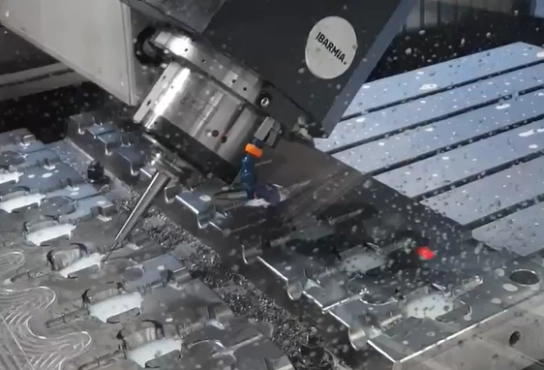

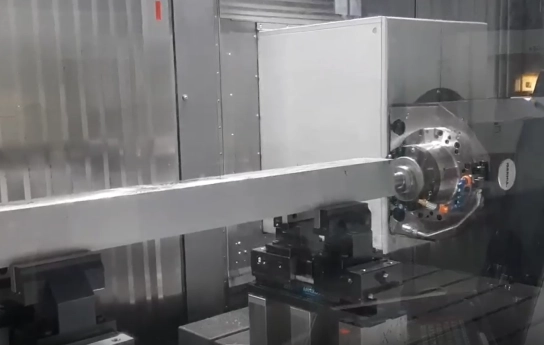

In order to reinforce its machining capacity, MAYMO incorporates an IBARMIA ZVH 48/L2200 EXTREME moving column machining center, a 5-axis model with integrated rotary table:

- Moving column architecture with 2,200 mm longitudinal travel, ideal for long and narrow parts typical of the mold world.

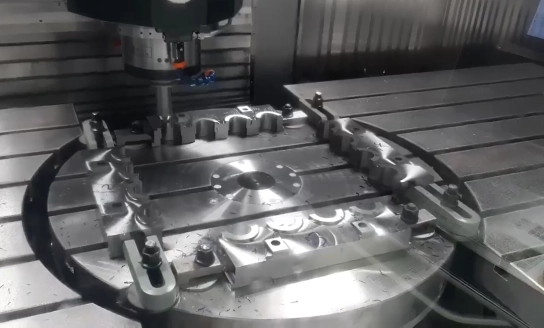

- Fixed table with high load capacity, allowing the machining of large bases and plates.

- Centered rotary table, ensuring optimal access to the workpiece and a balanced distribution of masses during machining.

- Continuous tilting head (B axis) combined with rotary table (C axis), enabling complete 5-axis machining in a single setup when required.

- Possibility to combine vertical and horizontal machining, keeping the fixed table always available for other configurations and tooling.

The ZVH EXTREME platform is also characterized by its high configurability, the integration of large diameter rotary tables and the ability to customize the work area and clamping systems according to the needs of each customer.

In the context of MAYMO, this combination of fixed table and integrated rotary table fits particularly well with the variety of parts typical of the mold sector: plates, mold holders, inserts, core holders and precision components.

Application at MAYMO: high-precision machining on demanding steels

MAYMO uses the ZVH 48/L2200 EXTREME for advanced machining operations on mold components, such as machining processes on AISI 304L stainless steel parts by trochoidal milling, using Ø16 mm tools.

This combination of:

- Advanced machining strategies (such as trochoidal milling),

- Structural rigidity of the moving column architecture,

- And 5-axis machining capability,

allows to tackle complex parts while maintaining process stability, something especially relevant in injection molds where any dimensional deviation has a direct impact on the quality of the final part.

Results: reliability and quality on a day-to-day basis

After two years of working with the ZVH 48/L2200 EXTREME, the balance at MAYMO is clearly positive.

The machine has been integrated as a key resource in the workshop, participating in the machining of mold components and associated parts with total process stability. This day-to-day reliability makes it possible to plan the workload with greater safety and to face complex 5-axis geometries with full confidence.

"2 years since the arrival of the IBARMIA ZVH 48/L2200 EXTREME, we couldn't be happier. Zero problems and top quality."

This testimony reflects two key aspects for a mold maker:

- Reliability: a machine capable of working continuously without incident translates into higher availability and meeting deadlines.

- Machining quality: the combination of geometrical precision and good surface finish is fundamental in injection molds for rubber and thermoplastics.

Besides, the good relationship between MAYMO and IBARMIA is publicly reinforced, thanking for the support and the treatment received during the project and the start-up of the machine.

Conclusion: a solution in line with the mold requirements

With the addition of the IBARMIA ZVH 48/L2200 EXTREME, MAYMO consolidates a machining solution which combines:

- Capacity for large and heavy parts typical of the die and mold sector.

- Flexibility for 5-axis machining of complex parts.

- Proven reliability in daily production.

- A close technological partner, able to adapt the machine to the real needs of the workshop.

For IBARMIA, the collaboration with MAYMO is an example of how the ZVH EXTREMEmoving column architecturefitsinto the MOULDS AND DIES sector, bringing tangible value to companies which have been setting the standards in the manufacture of injection molds for decades.