A tailor-made solution for integrated machining and unattended production in ABC’s Eibar plant

Success cases

BARTH bets on precision and green energy with IBARMIA's MULTIPROCESS technology

BARTH Präzisionstechnik GmbH has been machining high-precision parts for more than 50 years. Founded in 1970 and located in Binzwangen (Germany), the family-owned company operates with about 100 employees in a 6,500 m² plant. Its activities range from prototype parts to series of more than 50,000 units for demanding sectors such as automotive, aerospace, renewable energies or digital construction.

As of 2019, faced with pressure from the automotive market, BARTH initiated a strategy of industrial diversification into new sectors such as green energy and technologies for digital construction.

"Between 2015 and 2020, the price pressure in automotive reached impossible levels. In addition, the market changed with electrification and stopped focusing on the technical efficiency of the engine," explains Wolfram Barth, CEO.

The solution: IBARMIA's MULTIPROCESS technology

The turning point came with the purchase of his first IBARMIA machine: a THC 16 MULTIPROCESS installed in 2019. Chosen for its rigidity, thermal stability and precise kinematics, it laid the groundwork for the leap to larger parts and tighter tolerances.

The evolution continued with two new acquisitions:

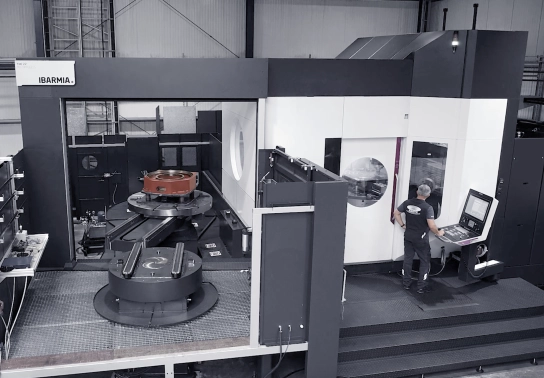

- THC 16 GEN2, on display at AMB 2024, equipped with Heidenhain TNC7 control, 134-tool capability, and thermal and collision monitoring sensors.

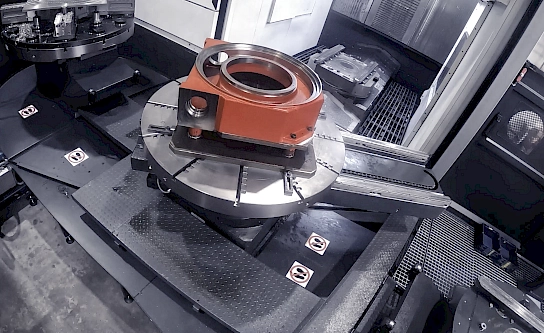

- THC 22 GEN2large-format machine with automatic pallet changer, ideal for parts up to Ø2,500 mm.

"We achieved 30 microns of flatness on Ø1.6 m parts. It was unthinkable before. With IBARMIA and Heidenhain, we even programmed complex routines to ensure process stability."

Unattended production and extreme precision

The new THC 22 GEN2 model has been a leap in productivity. Thanks to its automatic pallet changeover system and MULTIPROCESS capability (milling turned in a single setup), BARTH has been able to eliminate re-clamping, reduce cycle times and work autonomously during night shifts.

"Some parts now run at night without an operator. The first shift only has to change the part," Wolfram says.

"The THC 16 was key to taking our first steps into sectors such as hydropower or aerospace, with high-precision technical parts," says Barth.

A long-term strategic partnership

Beyond the technology, BARTH highlights the value of the technical support received. IBARMIA and its distribution partner in the region, Nagel Werkzeugmaschinen GmbH, were actively involved in the project, from the first demos to the final installation.

"They know how we think and what we need. Their expertise has made these investments smoother and faster," Wolfram concludes.

The future: energy, automation and sustainability

BARTH has already ordered a new THC 16 with pallet changer for 24/7 series production. It has also reinforced its investment in metrology with a new 3x2x1.5 m CMM and REVO-5 head.

Its objective: to increase its turnover in energy technology to 40% and to advance in decarbonization processes with the support of reliable technological partners.