MoM SOLUTIONS

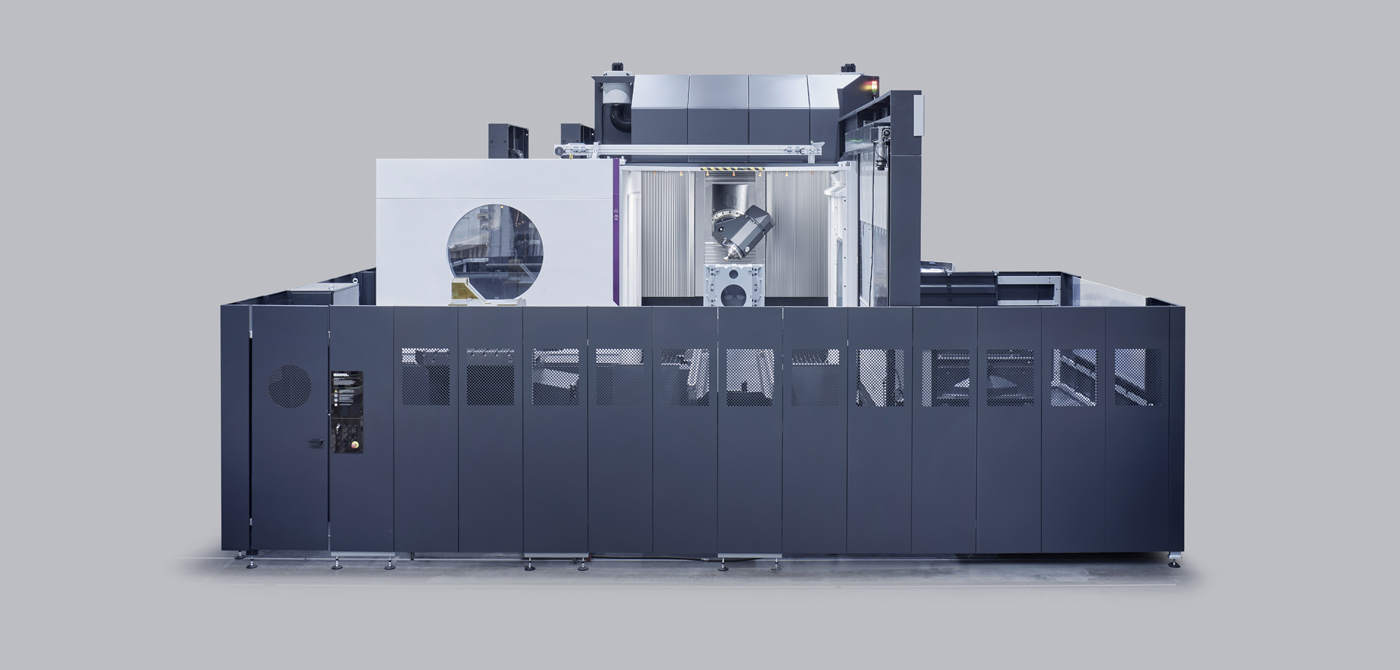

THC 22P EXTREME

Power, stability and autonomy for large steel components

The THC 22P EXTREME is built for those situations where the challenge is not only to machine… but to keep the process under control through long cycles, with large workpieces and real shopfloor demands. With a 5-axis kinematic concept designed to reduce set-ups, it combines a generous working envelope (X=2200 mm, Y=1600 mm, Z=1700 mm (+200 mm)) with a B-axis range from -15° to +195°, delivering access and versatility in a single clamping.

At its core, a motor spindle with HSK A100 interface runs from 30 to 12.000 rpm, delivering power and torque where it matters: 48 kW at 1500 rpm, 74 kW at 4000 rpm and 300 Nm. To sustain the pace, it incorporates a DUO magazine for 240 tools, optimised for HSK A100, and a coolant system ready for demanding cutting conditions, with dry machining capability.

Automation is built around an IBARMIA palletised rotary table rated for 10.000 Kg and 6500 Nm, integrated with a T22 pallet pool. Everything is managed by HEIDENHAIN TNC 7 (19”), with KinematicsOpt, teleservice and monitoring, plus probing and tool breakage detection to ensure repeatability, shift after shift.

DOWNLOAD THE CATALOG

DOWNLOAD THE CATALOG