MoM SOLUTIONS

ZVH 60/L4000 MULTIPROCESS

UNMATCHED VERSATILITY FOR MAXIMUM PRECISION ENGINEERING PARTS MANUFACTURING

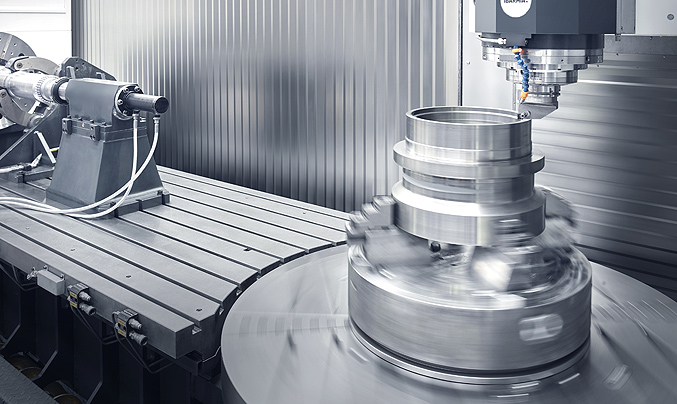

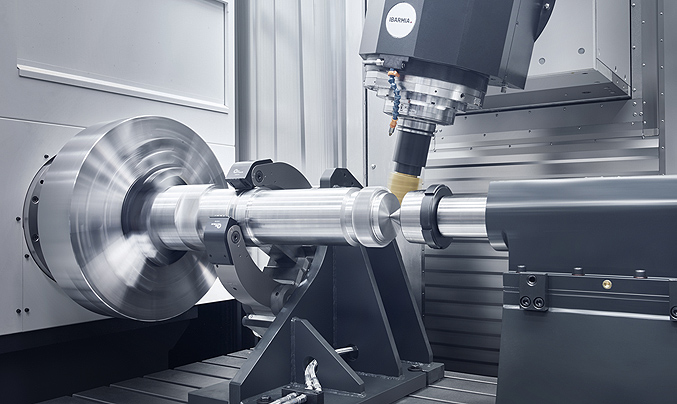

Machining center designed for machining 4 m long parts, with a 1800 rpm horizontal chuck with 3000 kg load capacity with tailstock, ø1400 mm turning in vertical turning operations up to 500 rpm.

The maximum virtue of IBARMIA's moving column platform lies in the flexibility it offers when configuring multiple machine typologies with the same basic ingredients; from 3-axis machining centers to the most advanced MULTIPROCESS models that integrate turning capacity on a 5-axis machining center.

Having reached this level of performance and adjusting to the maximum to the requirements of its customers, IBARMIA offers either the possibility of configuring models for the production of very specific machining parts, or models designed to manufacture parts of very different typologies by using a single machine. These are the virtues of multitasking which, taken to IBARMIA's moving column platform, allows the practical configuration of an entire machining workshop on a single machining center.

MAXIMUM VERSATILITY

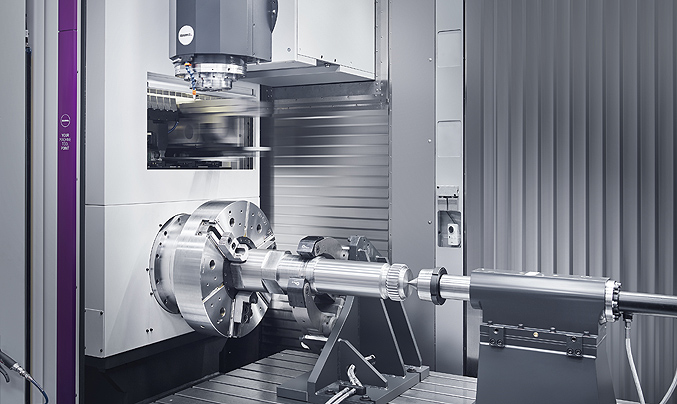

A long fixed table (4000 mm) with high load capacity, combined with a moving column equipped with a continuous turning head and torque motor that integrates a powerful electrospindle, plus an integrated rotary table. All this makes up a machining center that offers a wide range of possibilities. But what if we add turning capacity to a rotary table capable of carrying up to 6000 kg in milling operations? And what if, not enough with that, we also integrate a horizontal axis turning table at the other end of the machine, which we complete with the integration of an ATC for LBB (long boring bars for internal boring operations)? Well, you can go even further, when multitasking means adding to the machine's own virtue for advanced manufacturing, technologies for advanced gear hobbing and gear skiving.

The simple answer to this question is that we obtain a machine with unparalleled versatility, which makes it possible to tackle complex workpieces of up to 4 m in length by using a horizontal chuck of up to 1800 rpm with a load capacity of up to 3000 kg with tailstock, or turning of up to ø1400 mm on workpieces of up to 3000 kg in vertical turning operations at up to 500 rpm, all with a minimum number of set-ups and from the widest combination of machining operations.

That is how our customer, a manufacturer of engineering parts of high technological value in small prototype series, saw it as a key investment for this purpose.

The model also integrates a wall for pendulum work, doubling the machine's capacity, and a wide range of options such as cameras, probes and various systems for active control of the machine's activity.