MoM SOLUTIONS

THR 16P MULTIPROCESS

ADVANCED MANUFACTURING OF COMPONENTS FOR THE OIL & GAS SECTOR

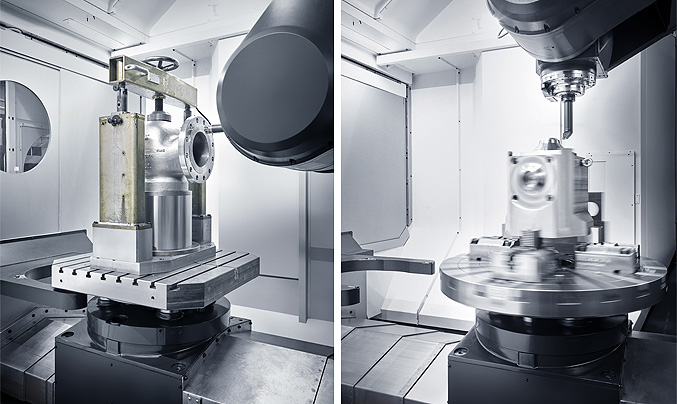

The high-performance THR 16P MULTIPROCESS model has been designed for the advanced manufacturing of components for the Oil & Gas industry. We refer to it as high-performance because it integrates two of the main drivers of modern machining into one machine: MULTITASKING and AUTOMATION.

Regarding multitasking, this machine is built for high-capacity machining, designed to handle 5-axis/5-face machining of parts up to ø1600 mm, 1700 mm in height, and 6000 kg in a single setup. This model not only excels in multi-face milling but also incorporates high-capacity vertical turning, thanks to its high-dynamic rotary table capable of handling parts up to 4500 kg at 500 rpm, and the integration of a U-axis head for interpolation turning. These combined capabilities enable the machine to drastically reduce the manufacturing complexity of the parts it processes, doing so with the reliability provided by a powerful CAPTO C8 electrospindle of up to 84 kW and 12,000 rpm, designed to handle the high-resistance materials (superalloys, stainless steel, etc.) characteristic of the Oil & Gas sector.

In terms of automation, the machine features a compact system for quick changeover between two tables, each designed for different operations. This system aims to eliminate non-productive times associated with part preparation, allowing the operator to configure one reference while the machine works on the other. To further enhance efficiency, the model also incorporates an external probing arm for part measurement.

In summary, the THR 16P MULTIPROCESS is a high-performance machining center capable of integrating several functions into one machine.

View previous Machine of the Month

SUBSCRIBE TO OUR NEWSLETTER

Subscribe to our newsletter to receive more content like this.

SUBSCRIBE

SUBSCRIBE

SUBSCRIBE TO OUR NEWSLETTER

Newsletter

Want to know more?

SUBSCRIBE TO OUR NEWSLETTER

Subscribe to our newsletter to receive more content like this.

WANT TO KNOW MORE?

Contact us to learn more about our solutions