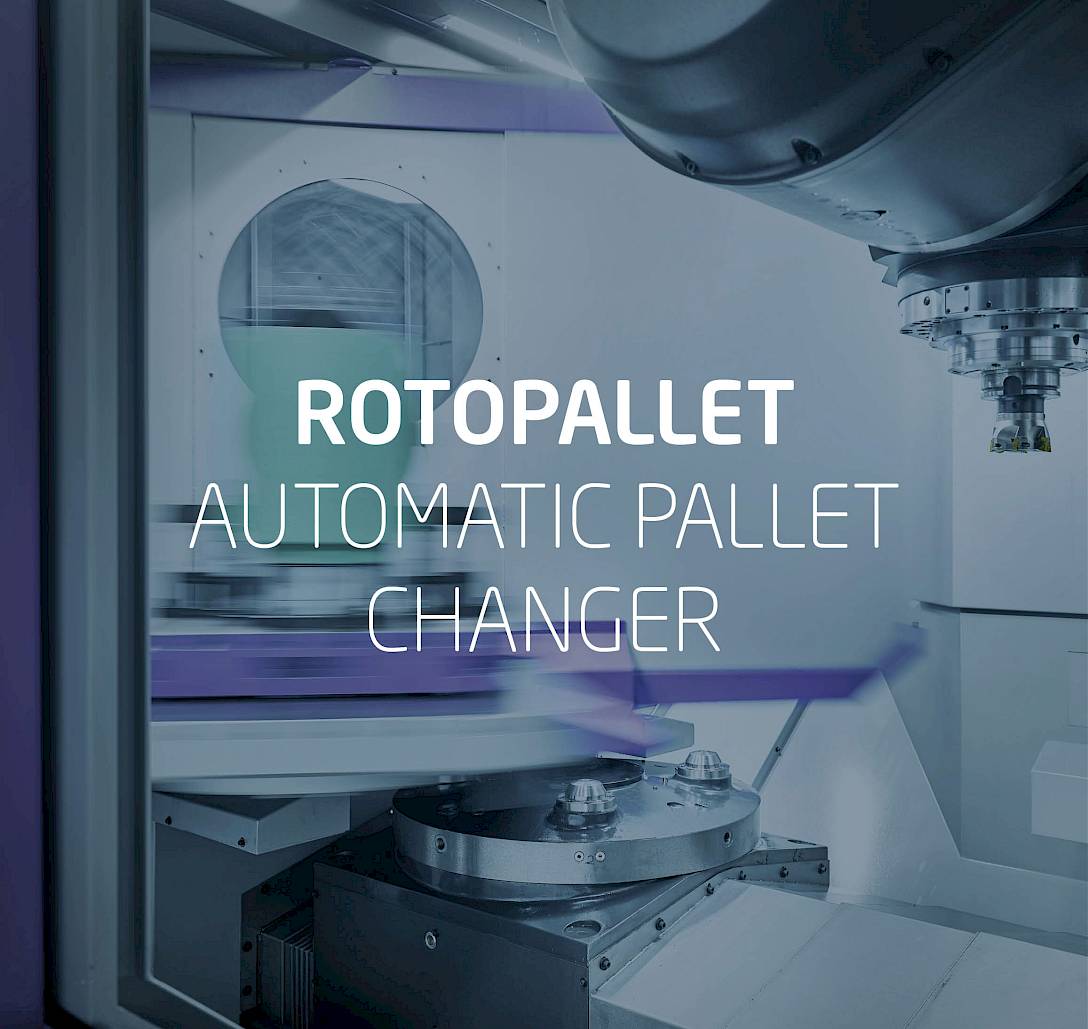

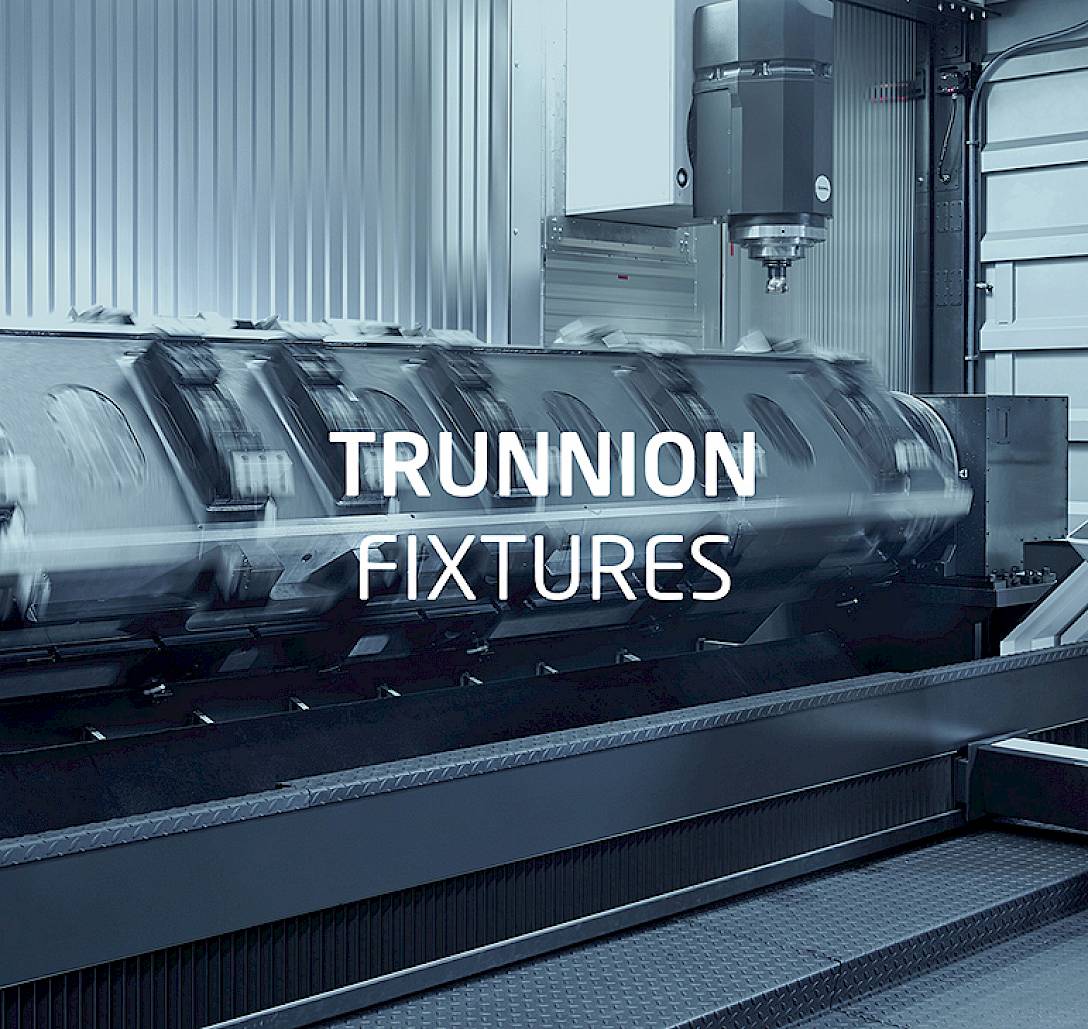

A compact and high-technology machine needs to have a system to prepare the next job while the machine is working

New

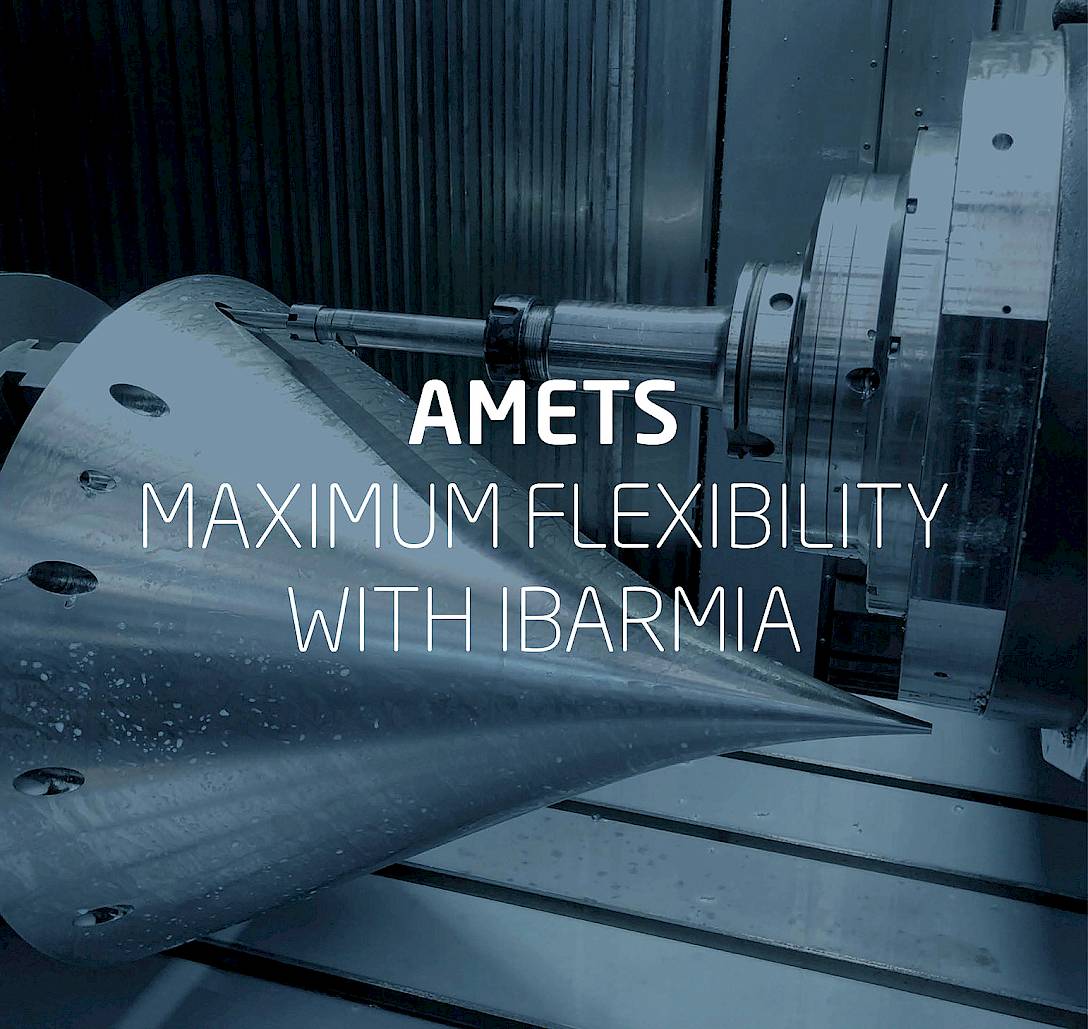

AUTOMATION: Rotopallet Automatic Pallet Changing system for T12 and T16 machine models

The IBARMIA T Series is designed for getting high productivity in 5 axis machining of heavy parts thanks to its high load capacity rotary tables and powerful spindles. Our range of universal 5 axis machining centers offers a modern range of solutions for the most demanding sectors by using the multi-function and automation capacity of machines. The IBARMIA T Series covers 5 different models depending on the axis travels and swing diameter of the working area: T12, T16, T22, T30 and T36 for travels that go from 1200 mm to 3600 mm.

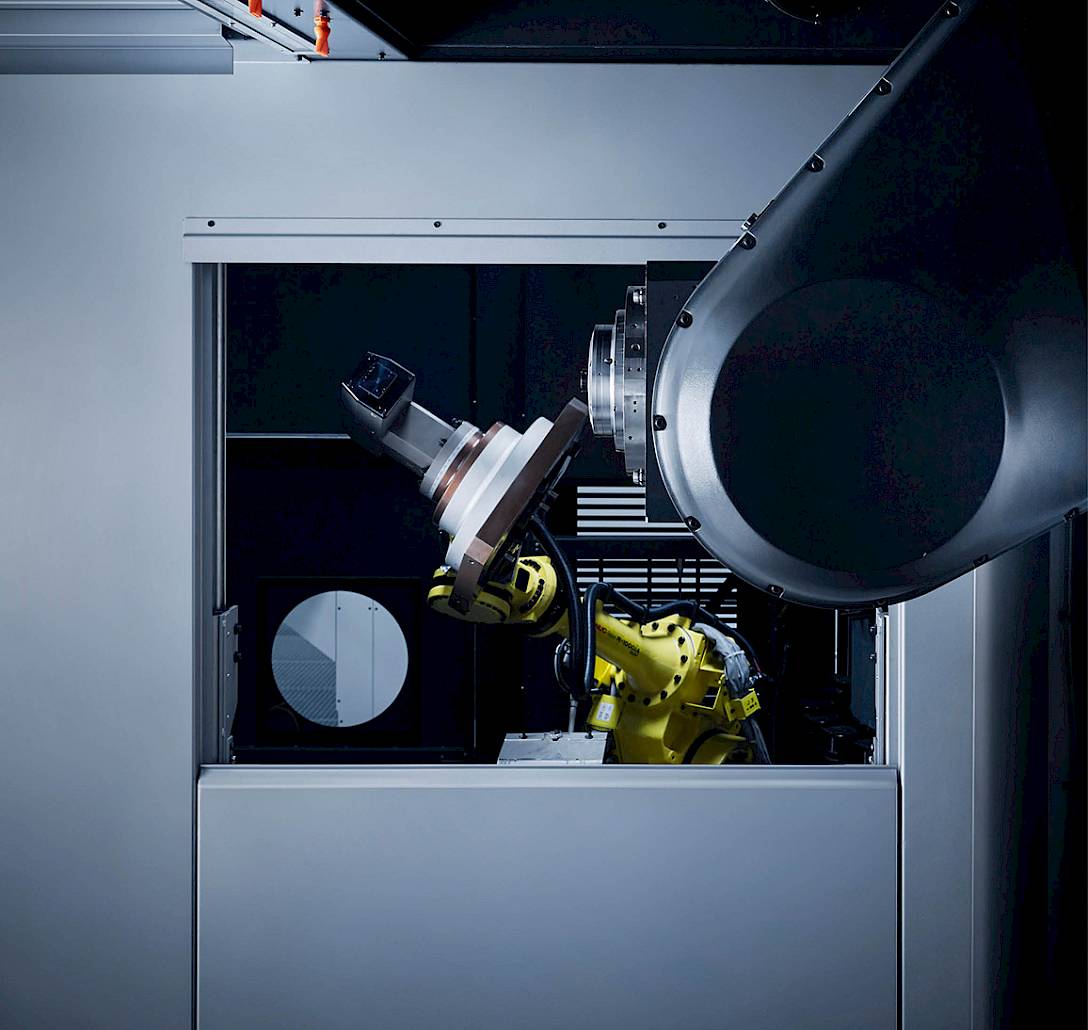

Nowadays, along with the machine automation systems, the machining cycle time of each part to be machined is becoming more and more important for many workshops. In various industries, every second counts and can lead to a great loss of money if the machining times are not optimized.

Among our range of universal 5 axis machining centers (T-Series) we highlight the multi-purpose T12 and T16 machine models with Rotopallet system. A compact solution to process parts up to ø1600 mm swing and 6 t weight. The Rotopallet consists of a quick pallet change system executed by a double fork in the machine front. This increases the autonomy and production by considerably minimizing the floor space. While one of the parts is being machined the operator prepares the subsequent part reducing all the set-up times. This loading position can also be turned manually for a more ergonomic access to the workpiece.

Thanks to this system, the T12 and T16 machine models, in addition to their high load capacity and adaptability to a wide range of requirements of multiple industrial sectors, stand out as a compact solution for getting high productivity in the advanced machining of complex geometry parts of medium and medium/large size.

Download the catalogue

T SERIES CATALOGUE

Fill in the form to download the catalog

01