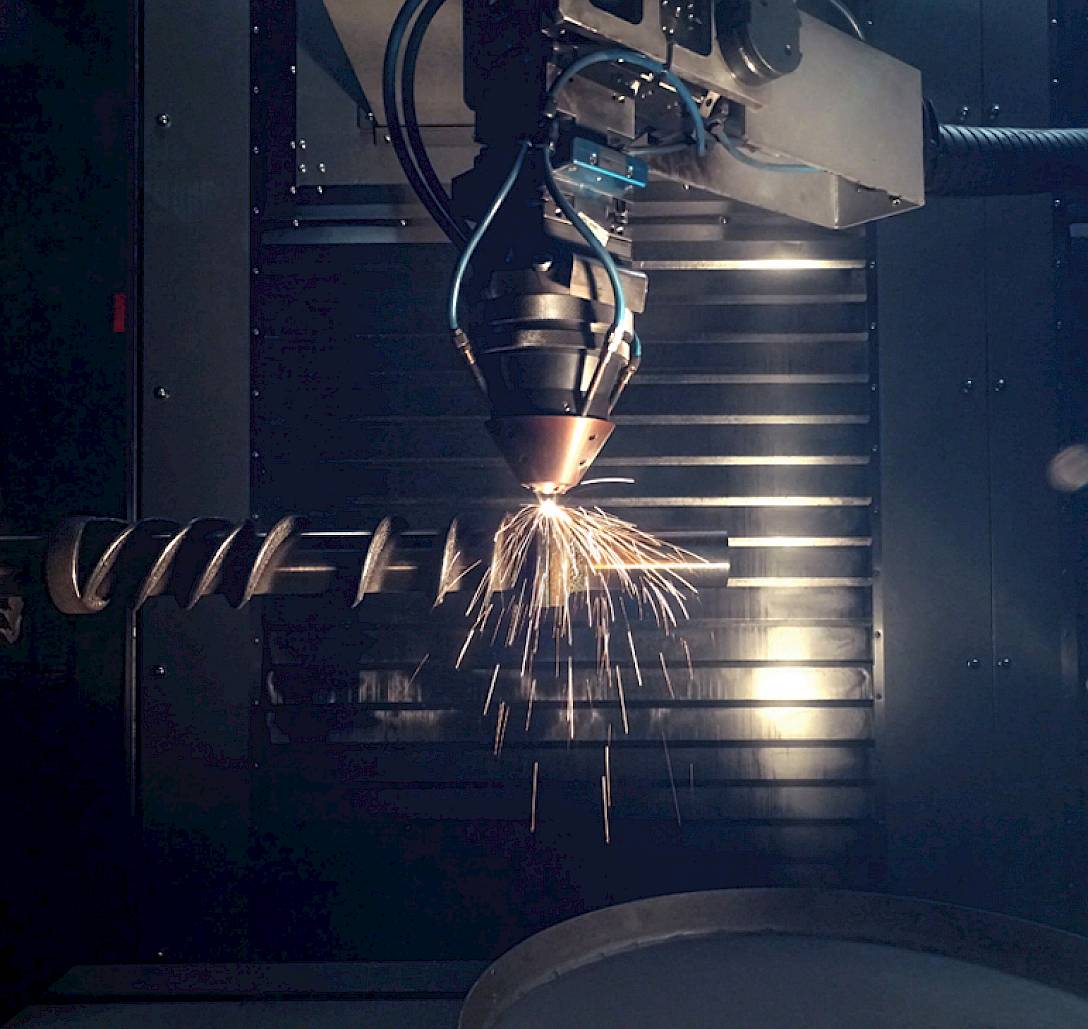

Manufacturing more, doing it better and investing less time in the processes is summarised as an improvement in production efficiency, an essential requirement to keep meeting the challenges imposed by today's market and for which industrial automation is a key factor.

New

AUTOMATION PORTFOLIO IN IBARMIA MACHINE PROGRAMS

Events such as digitalisation and Industry 4.0 are phenomena that were already on the way of course, before we decided to narrow them down and specifically label them. Whether the current situation has been imposed out of necessity or necessity has resulted from the current situation, the truth is we are being peppered with concepts derived from commercial and or political interests (which amount to the same thing), whose meeting with day-to-day reality is more diffuse than it may first appear.

On the road towards these new paradigms, it turns out that some were already on the way, some wanted to set off but did not find the way to do it, and lastly, those whose need were rather relative. In summary, a complete amalgam of realities.

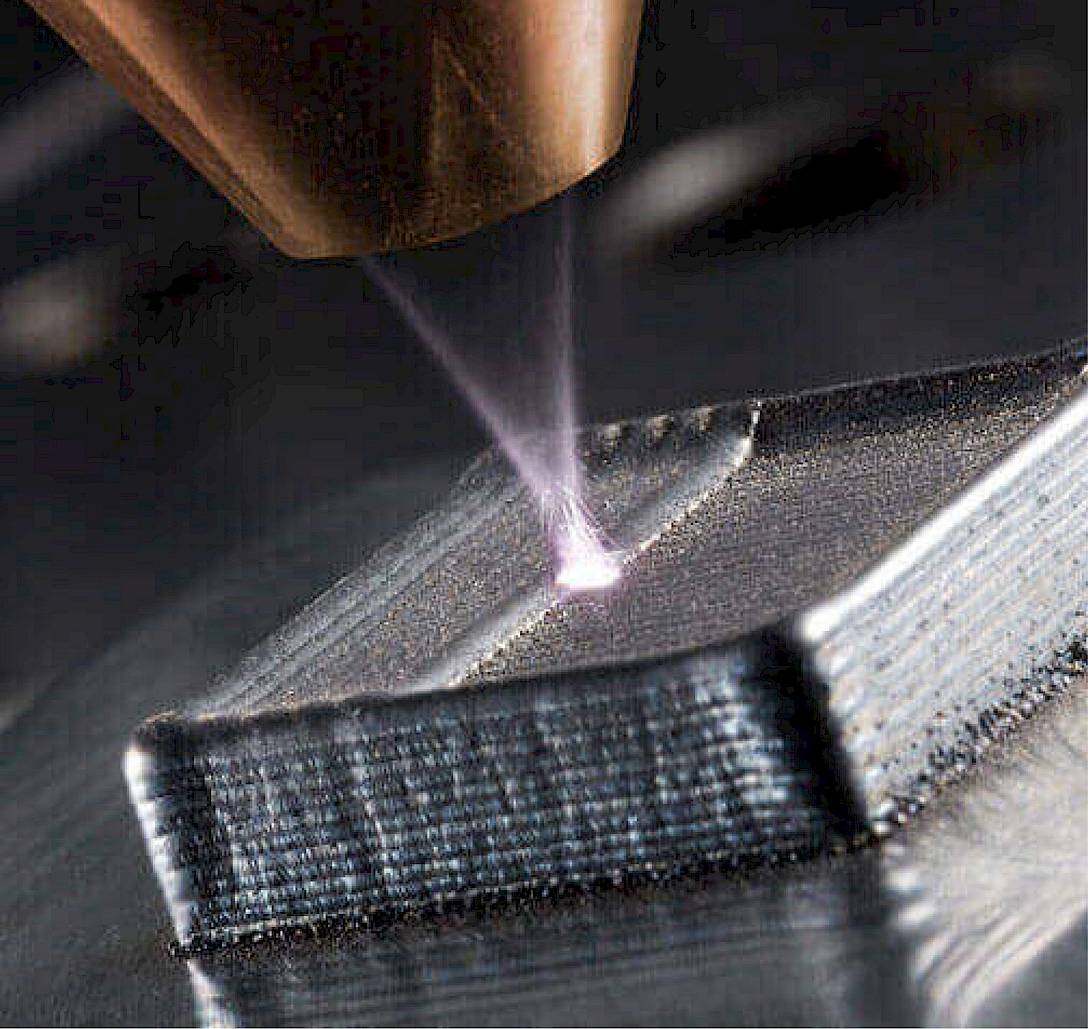

Objectively, however, all around is compressed and tense; we are growing in number... and needs whose satisfaction requires extreme competitiveness and imposes, in turn, a pace on all the processes never known before. Thus, although the map of industrial realities is widely varied, it is undeniable that the fact of having to do more, better and in less time, is something that needs to be addressed by the whole industry sector. Taking this to our sector, we all understand that automation is a driver and one of the fundamental points of what is called Industry 4.0, the variety of which can be translated into every possible aid or assistance to the operator, the very extreme of which fully independent operation of the machine and production without the operator. Be that as it may, and as four arms are better than two, automation is a key element of Advanced Industry aligned with the reality of the current market.

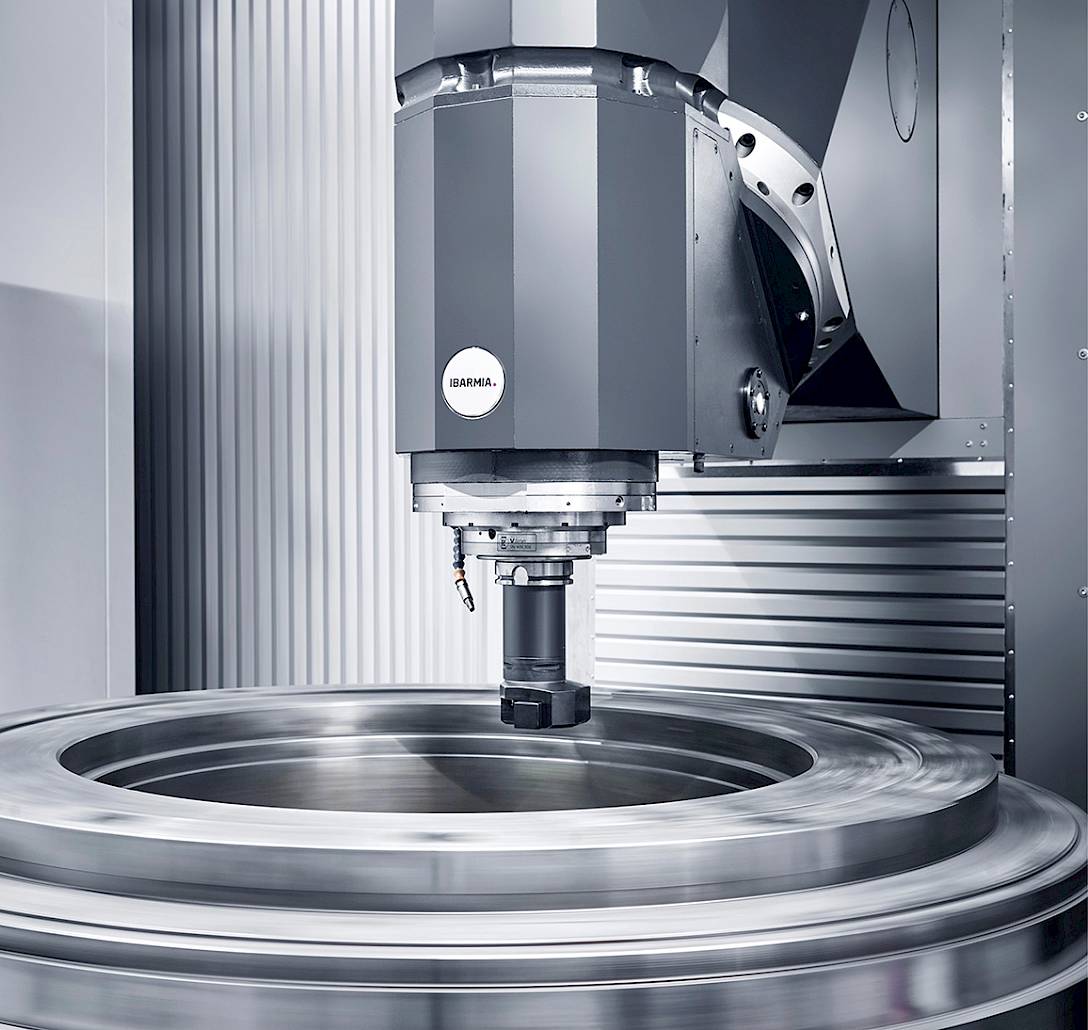

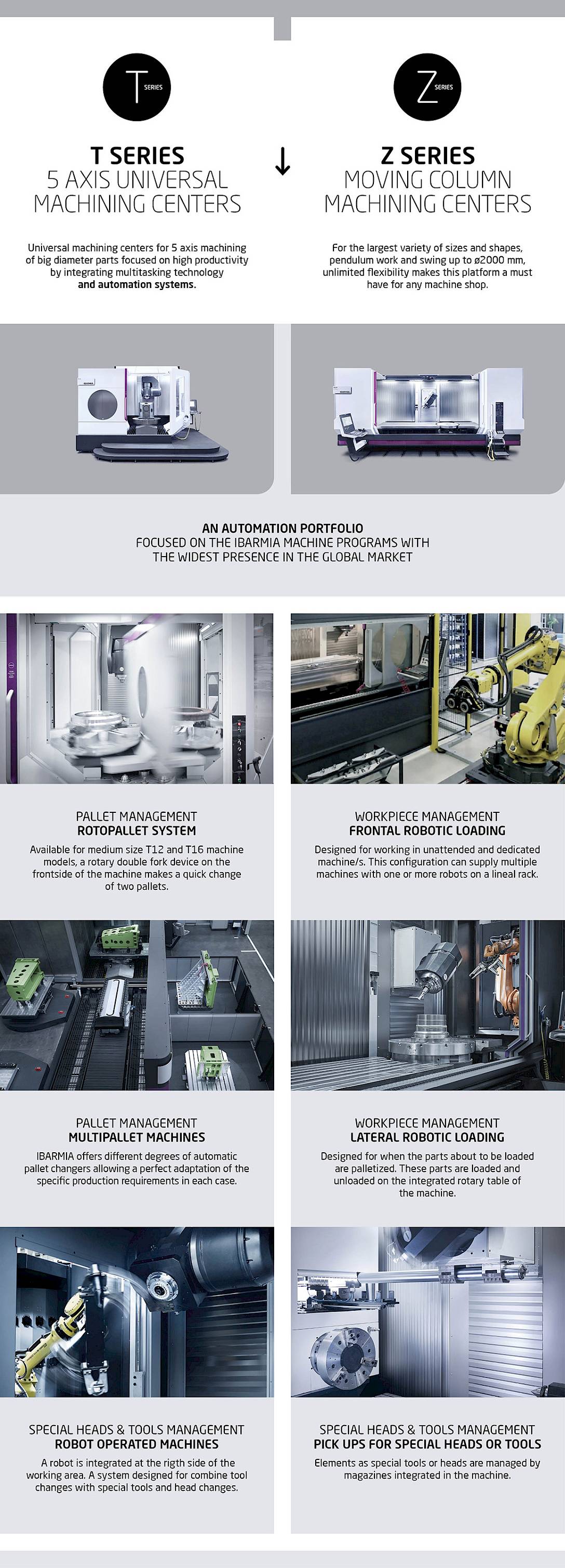

IBARMIA has a range of perfectly balanced products designed to respond to the various needs of the markets at which this aforementioned amalgam of realities is aimed. Let ‘s have a look at the various integrated support processes in IBARMIA’s T SERIES and Z SERIES programs that, as the range itself, vary depending on the industrial reality at which they are targeted.

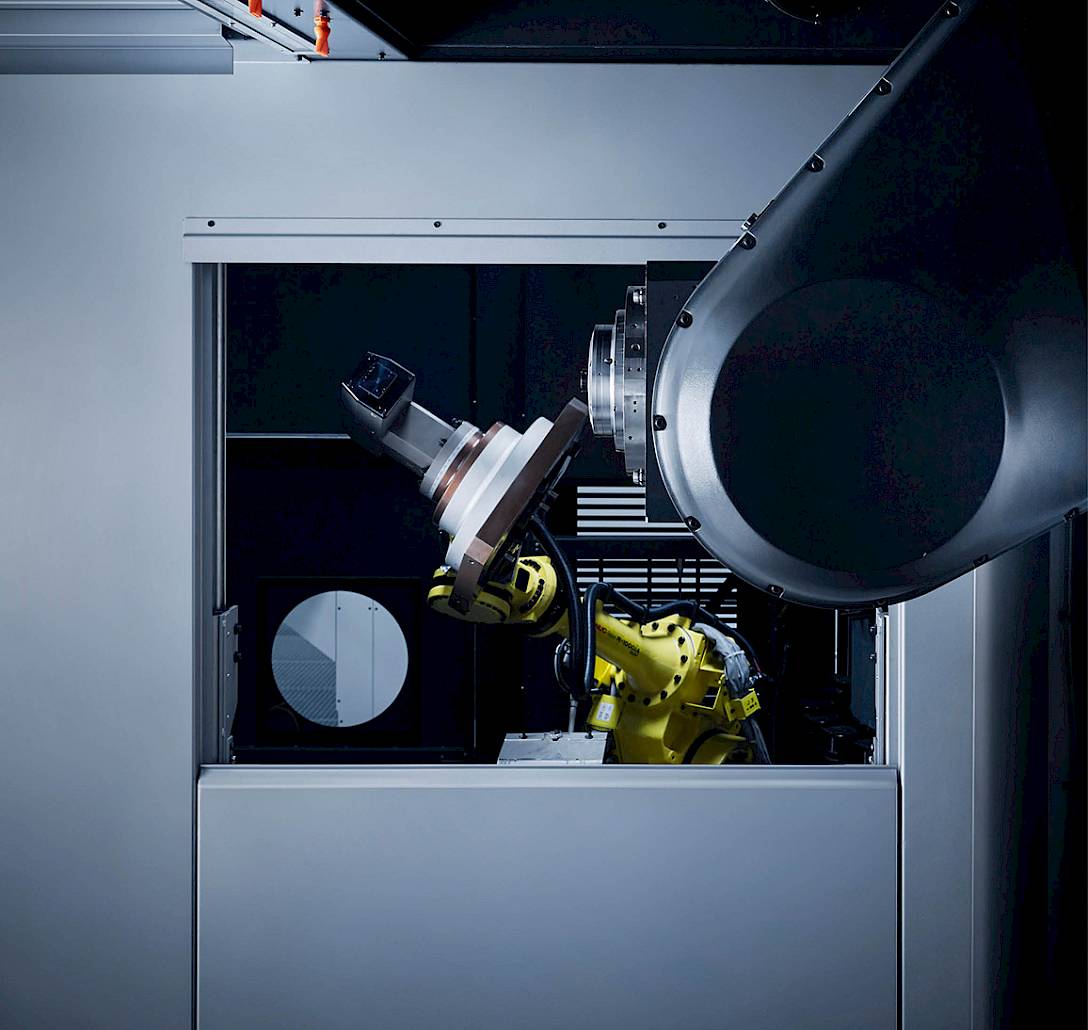

The automation processes that we can distinguish in our machinery range are the following:

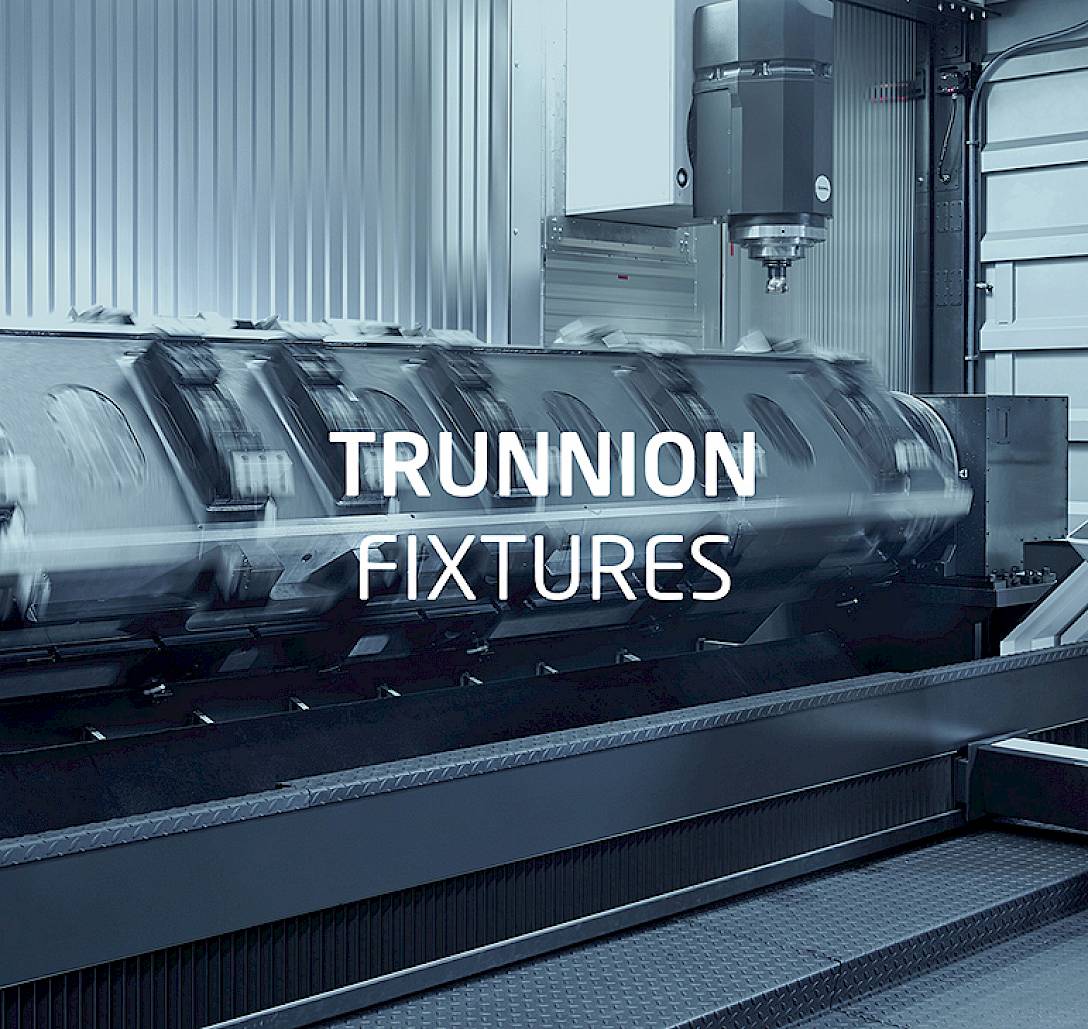

1_ Pallet management

Systems for storage and automatic change of working table.

2_ Workpiece management

Workpiece loading and unloading.

3_ Management of special tools and heads

Storage and automatic change of special tool and heads.

In view of the processes and as regards the degrees of automation, we can talk about two assistance levels. On a first level, that of shared ergonomics, operator and machine assisting each other. On the second level, production cells that operate completely autonomously, whether a single automated machine or an autonomous system made up of several automatically assisted machines.

Going back to the subject of diversity, we can summarise that the range of IBARMIA’s automation solutions is as varied as the requirements of the customers, which is no small thing.

01

Download the catalogue

Download the catalogue