The IBARMIA’s sliding tables system on moving column structure, a solution tailored to the production needs of this belgian manufacturer

New

THE ZVH EXTREME MACHINE WITH CUSTOMIZED MOVING TABLES KEEPS PICANOL AHEAD OF THE GAME BY INCREASING QUALITY AND SAVING TIME

Picanol, is a leading company that develops, produces, and markets high-tech weaving machines since 1936. With an increasing demand for wider weaving machines, Picanol renewed their machine park with 2 IBARMIA ZV EXTREME and 5 IBARMIA ZVH EXTREME machines, 4 of them with moving tables, that enable to adapt the position of different fixturing devices to the customer's different part lengths.

With more than 175,000 weaving machines installed worldwide, Picanol has been playing a pioneering role as both a developer and manufacturer of highly productive weaving machines since 1936. The head office is located in Ypres (Belgium), and the company also has production facilities in Asia and Europe, linked to their own worldwide service and sales network.

The market is evolving rapidly, with an increasing demand for wider weaving machines, up to 5.40 m, what means that the structural elements of the weaving machines are also becoming wider. The Belgian company already had 8 machining centers with a 5 to 6 m heading on their shop floor, but these wider structural elements required a 7 m heading.

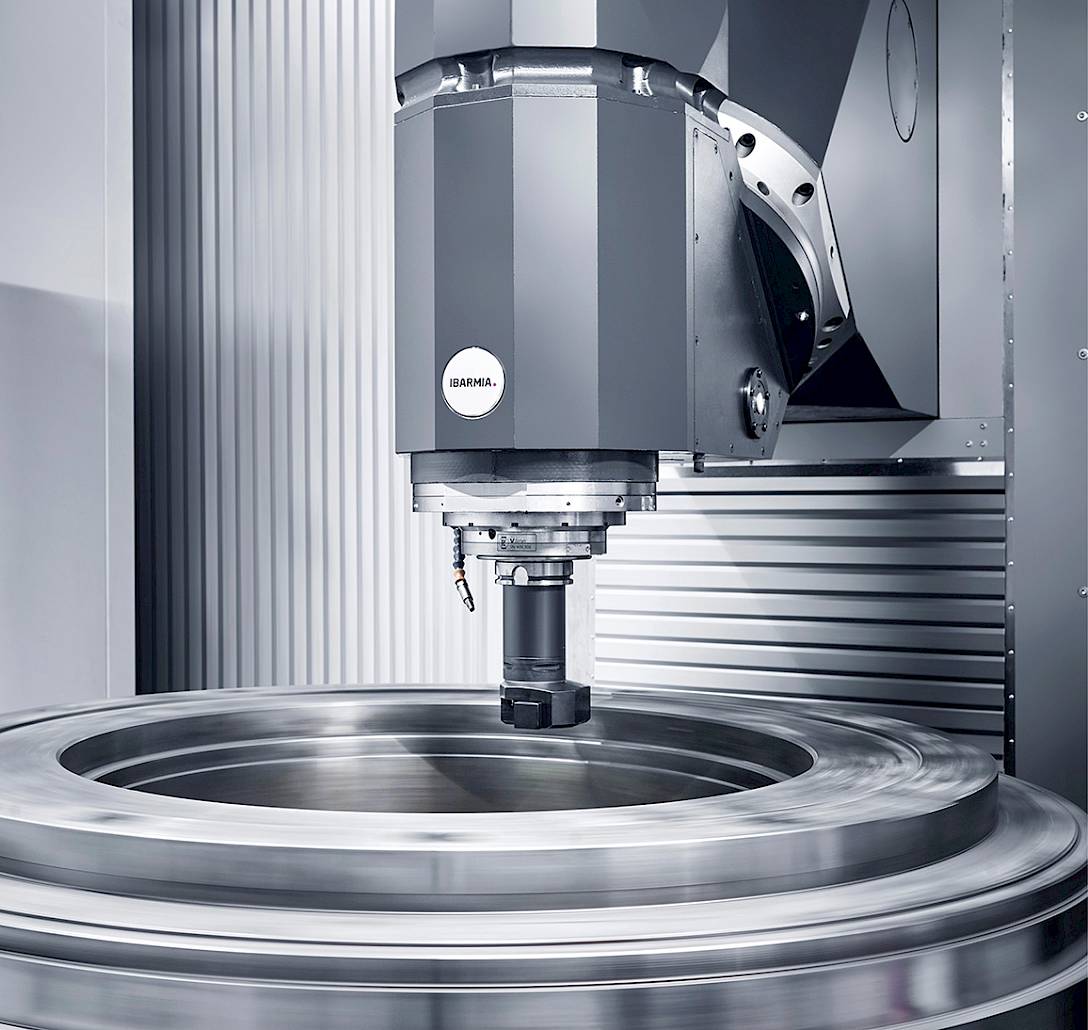

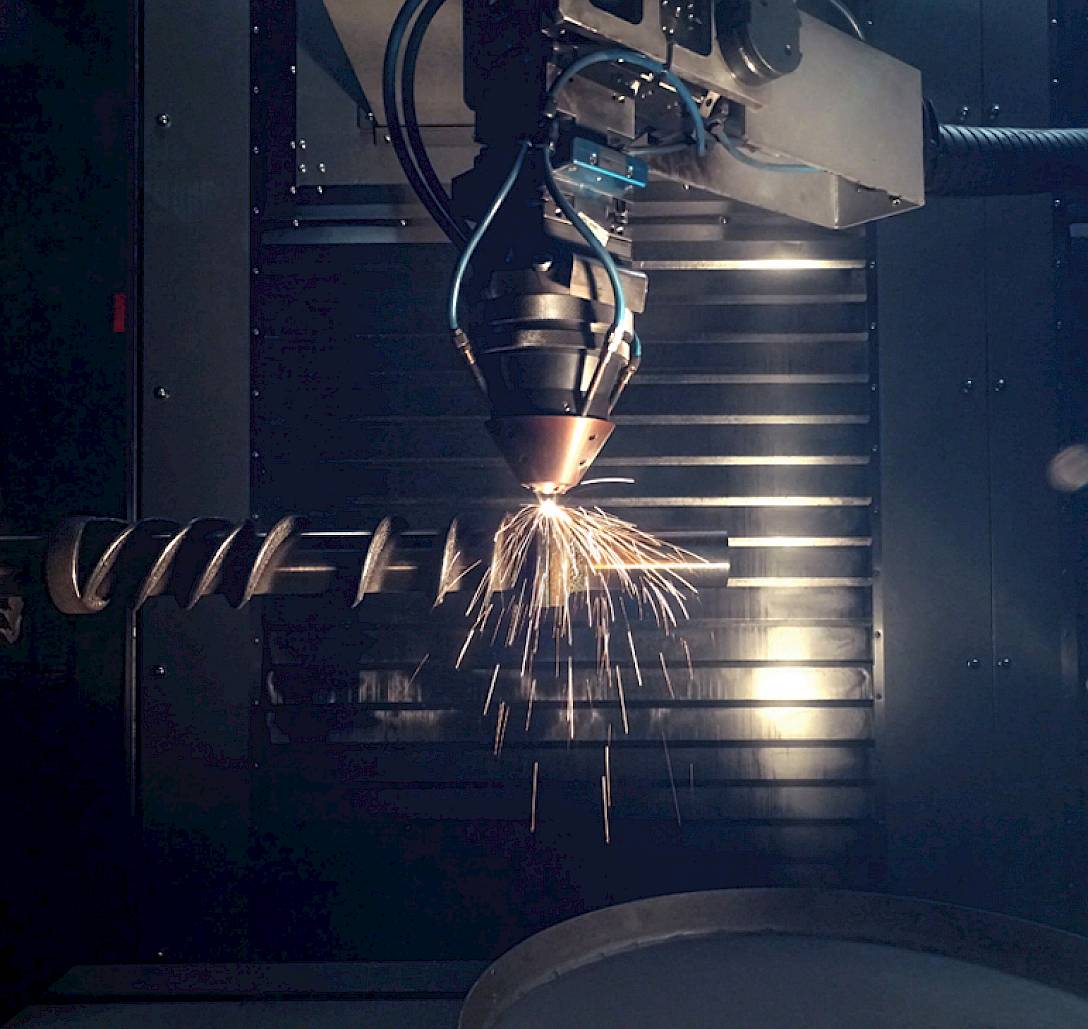

For the production of those long structural elements, which today can be up to 5.40 m long, the 'Long Pieces' production cell had to look for a new machining center. After much deliberation, Picanol chose IBARMIA’s ZVH 55/L7000 Extreme machining center, adapted to the department's needs. The simultaneous 5-axis pendulum milling machine with an igneous speed of 45 m/min is equipped with a continuous B-axis for angular machining, guarantees a spindle speed of 9000 tr/min and has an X, Y and Z axis of 7000, 800 and 1100 mm respectively.

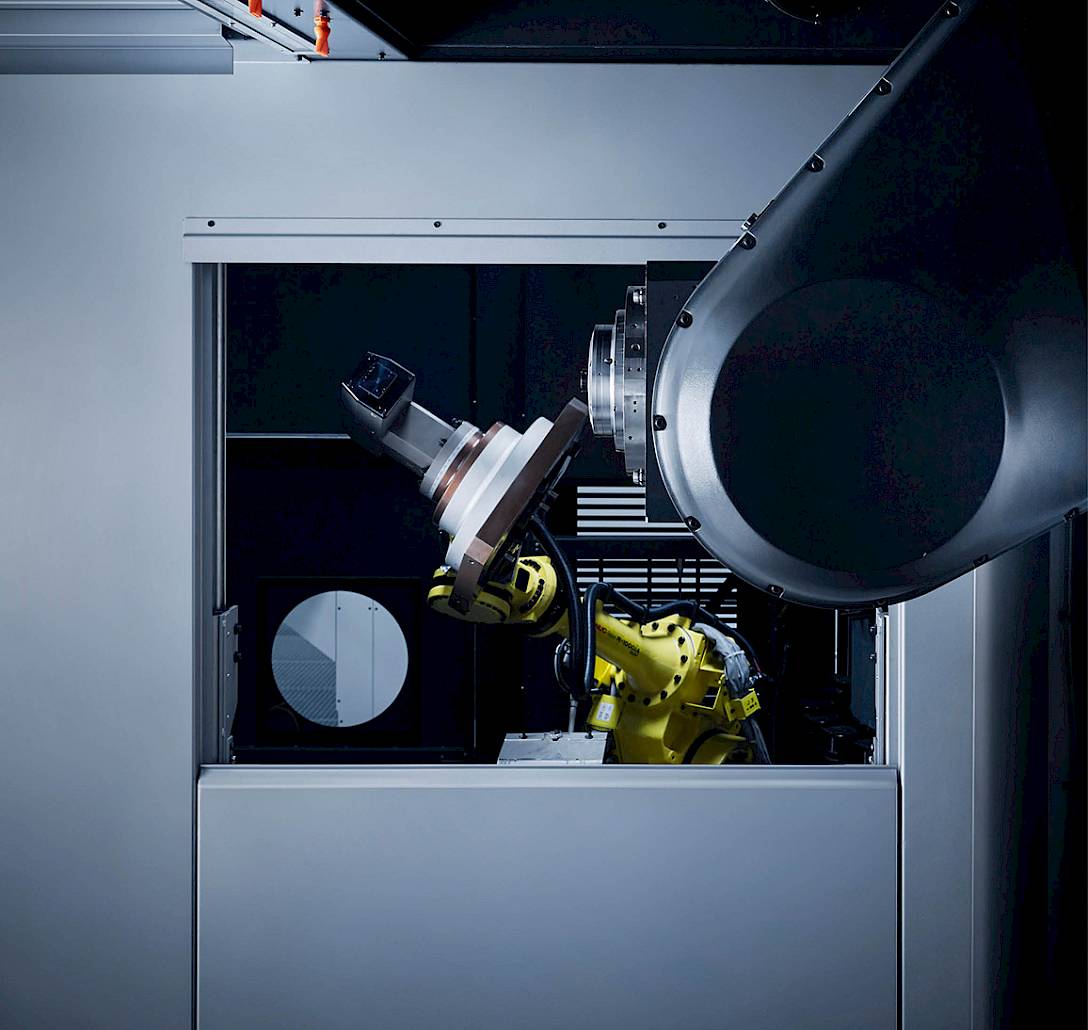

The “Long Parts” production cell required very specific needs for this application, so the IBARMIA Z series machines where perfect for them, as these machines are distinguished for their flexibility and versatility to adapt to the demands of the customer. The fixed table, for example, offers the possibility of integrating one or more rotary tables in or on the table, allowing to rotate and adding one or more controlled axes to the part itself.

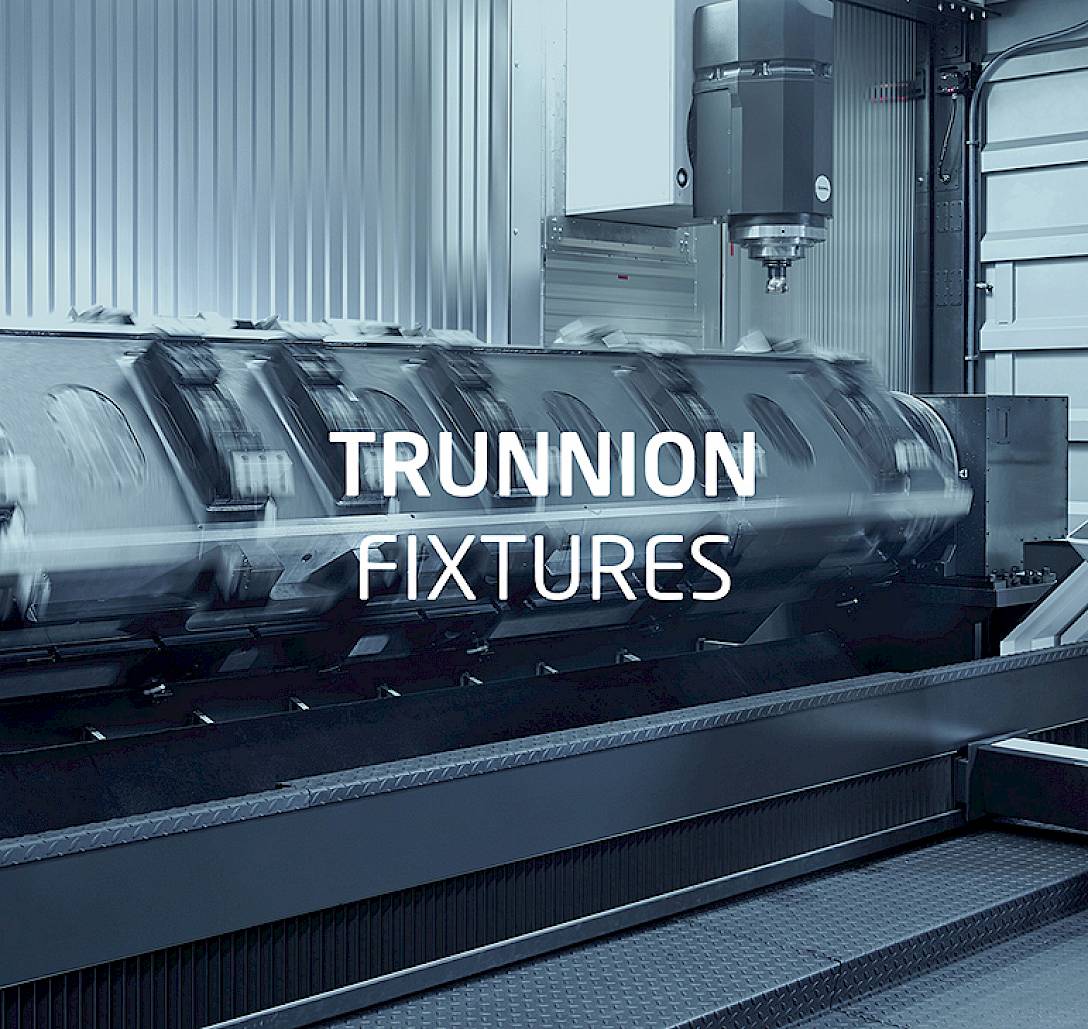

"The machining center is now proving its worth. All productivity targets have been met and exceeded without any problems.” says Henk Ryckeghem, Machining Supervisor. After seeing the great results obtained with the first machine, the Belgian company decided to install 4 more ZVH EXTREME with moving tables and 2 ZV EXTREME machines with trunnion table, with 12000 and 20000 tr/min spindle power.

For the moving table solution, the fixed table of the ZVH EXTREME was replaced by a set of 6 moving tables with 2 linear guides, making it possible to adapt the position of all elements such as bolt in rotary tables, tailstocks, steady rests, vices and other fixturing devices, that allow to adapt to the different part lengths in a more agile and efficient way and reduce set up times drastically. These moving tables can also be used as “tool following steady rests” to machine long parts faster with better quality.Thanks to the integrated Zero Points, Picanol can now quickly interchange vices, steady rests, tailstocks, etc. on the table, saving much time during their production process. Supervisor Machining Henk Ryckeghem tells that "thanks to the special clamping concept, for example, the machine takes less time to drill 5 separate holes than our previous machine to drill 5 holes at once."

In this project, too, IBARMIA and Germond delivered a suitable solution based on the needs of the customer and his production. "Without a successful collaboration between all partners, the machine would never have looked like this”, says Hans Donck of Germond. “Together with Henk Ryckeghem, we also worked out an adapted training schedule. The operators first received basic training, then advanced training, and in the future a third part will follow around the Shopmill business."

From IBARMIA to Mars

The Belgian company has been a key member in the success of MARS 2020, which is, to date, the most ambitious mission by humanity in search of extraterrestrial life. On the 18th of February 2021, the Perseverance spacecraft faced the most critical moment of the mission to Mars: landing with a parachute that had to deal with extreme conditions, it had to be ultra-light, heat resistant and strong enough to deploy when the travel speed was over 16 times the speed of sound and decelerate to 350km/h.

With this challenging requirement NASA - National Aeronautics and Space Administration opened the European circle by giving such responsibility to Heathcoat Fabrics Limited, British manufacturer of high level textiles. The fabric was then weaved with the highest European technology: OptiMax-I from the Belgian company Picanol Weaving Machines, one of the most advanced machines for this type of technical task. And closing that European circle, we have the “machine to produce machines”, as PICANOL use IBARMIA machining centers to make the components of their high-level equipment.

SUBSCRIBE TO OUR NEWSLETTER

Subscribe to our newsletter to keep up to date with all our news.

SUBSCRIBE

SUBSCRIBE

SUBSCRIBE TO OUR NEWSLETTER

01