Every change entails an opportunity and the new reality demands companies capable of adapting to different jobs at high speed. To do so, they need machines that can provide a wide range of solutions in the same space.

New

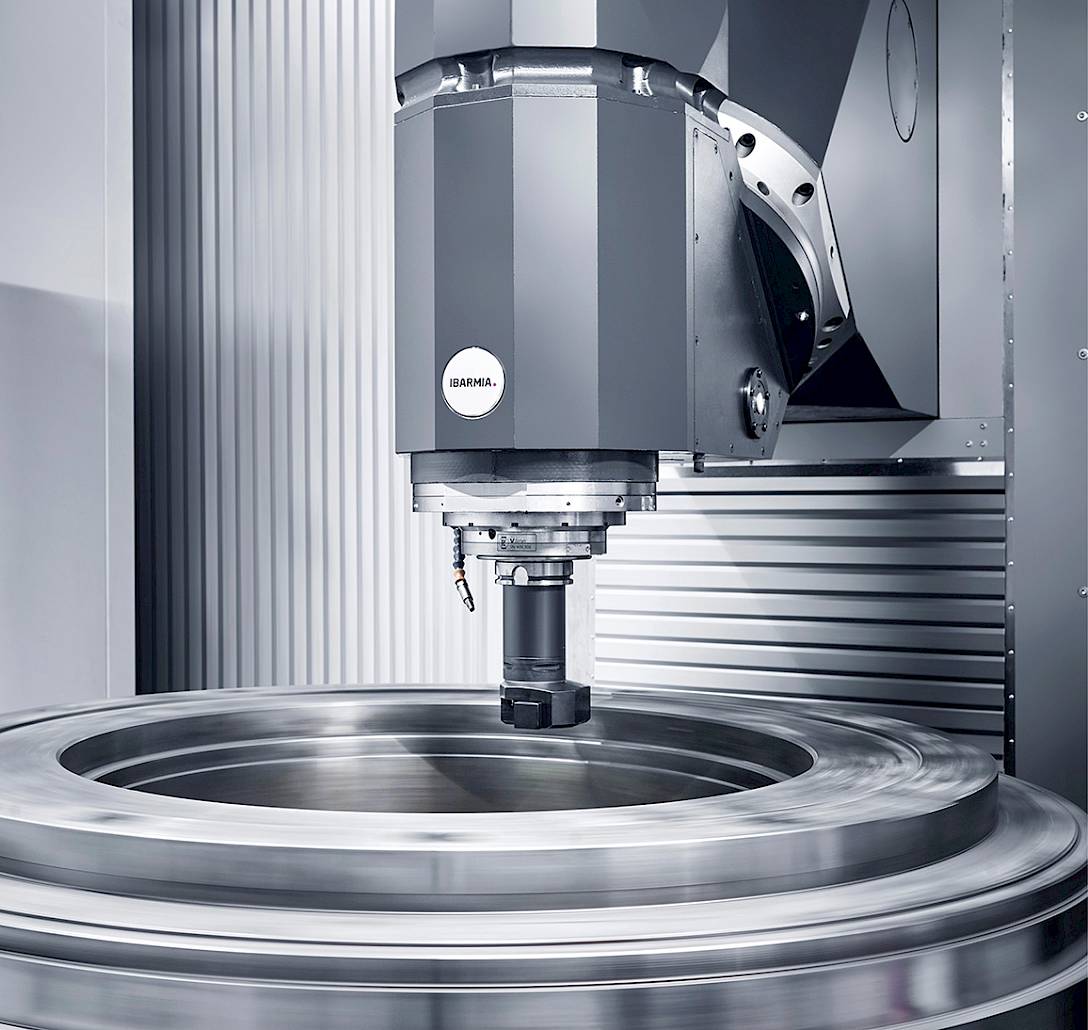

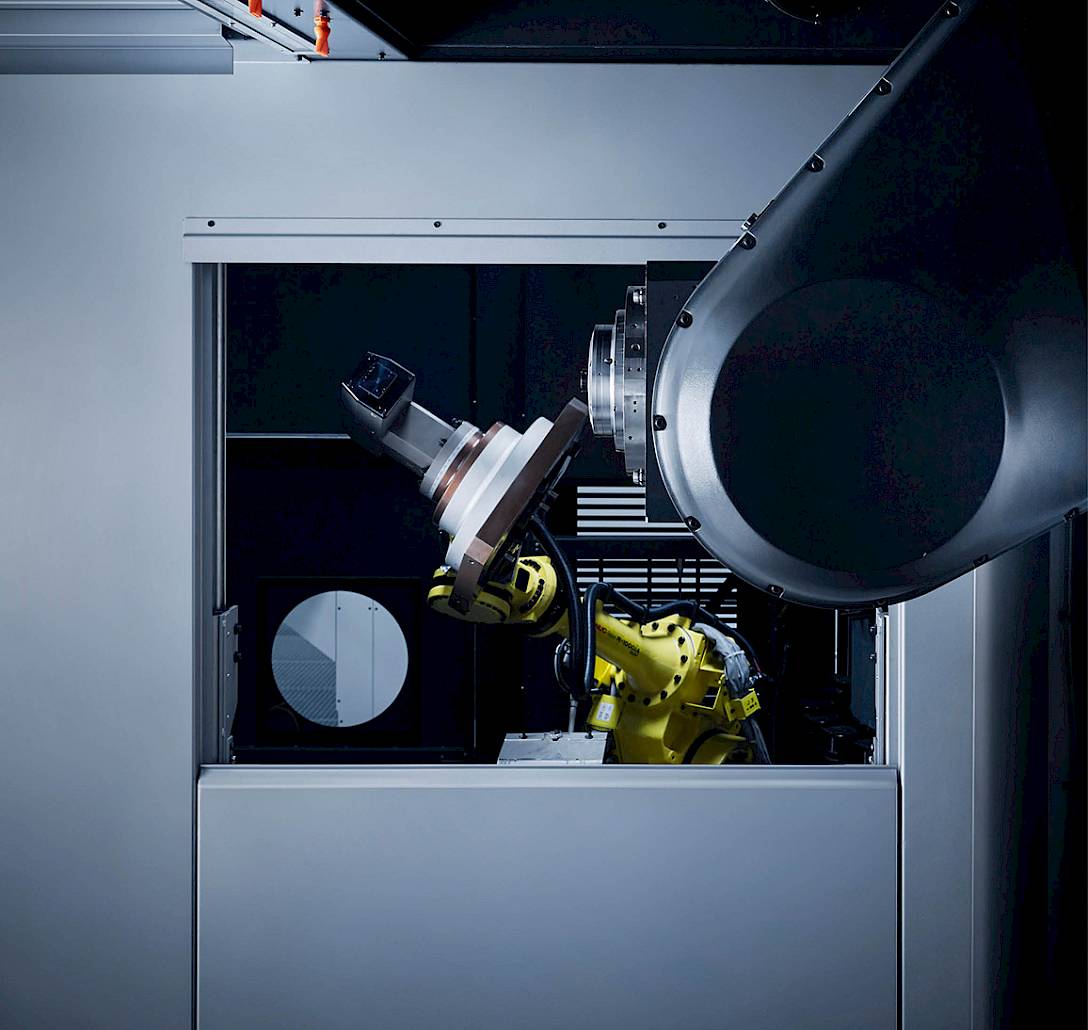

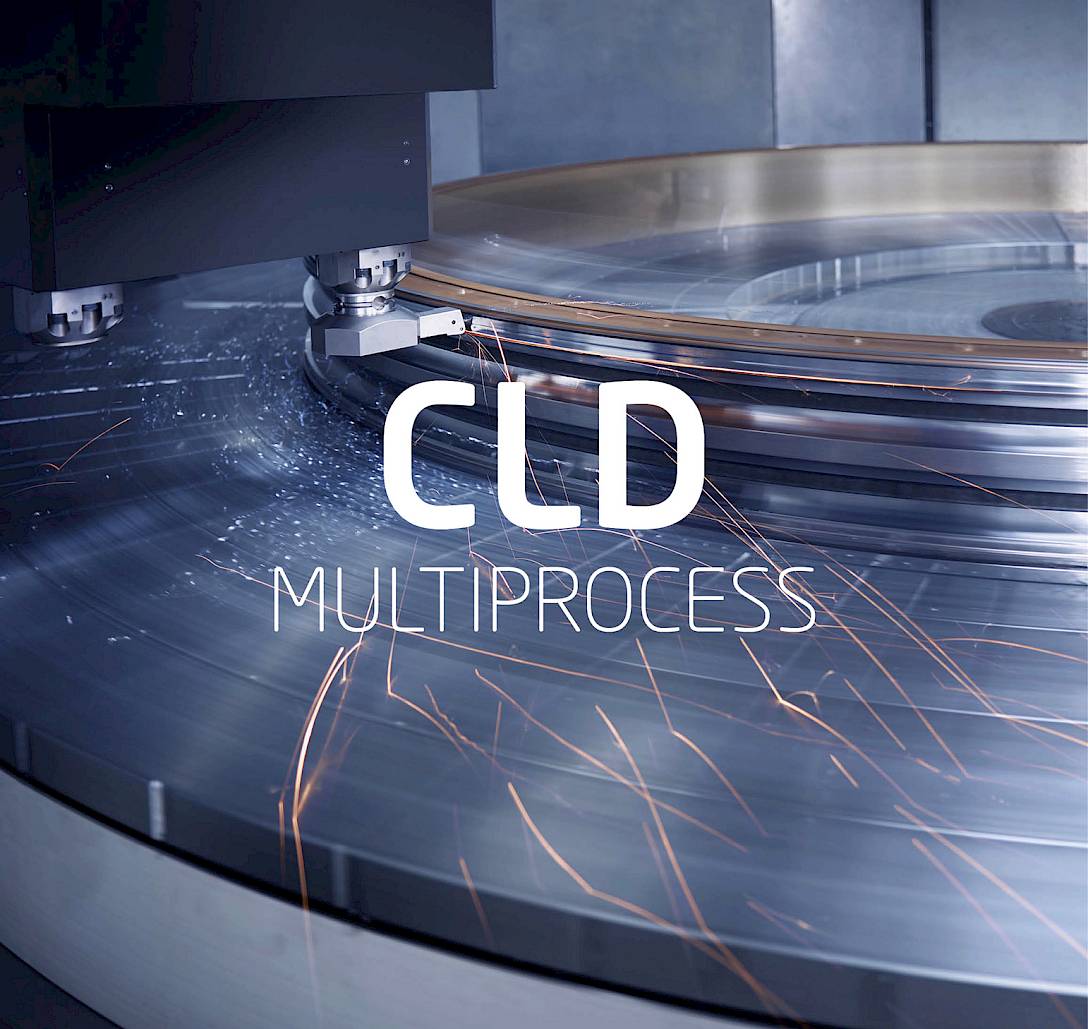

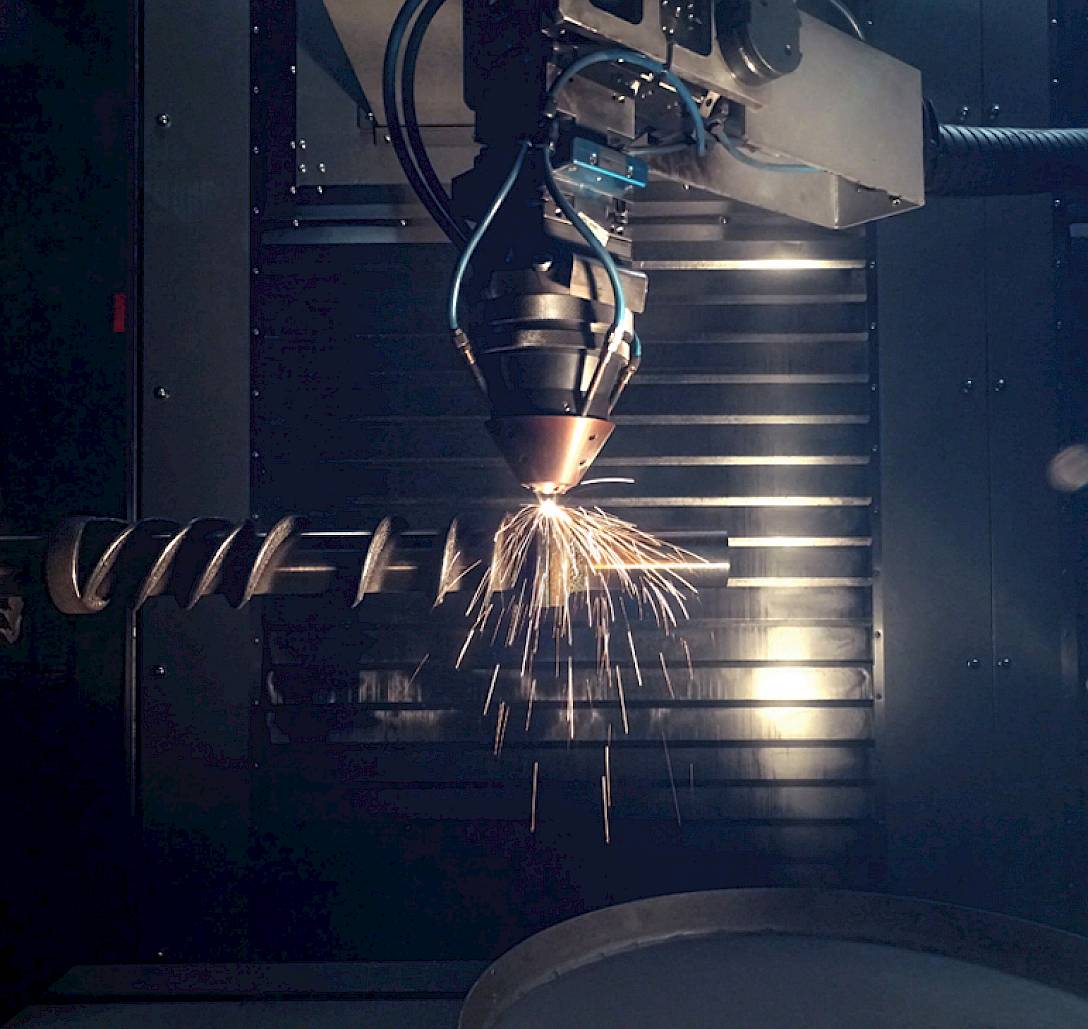

ZVH MULTIPROCESS IN #50 BODY SIZES; THE SWISS KNIFE OF THE MACHINE TOOL WORLD

Because the world is undergoing rapid change. The Covid-19 pandemic created a new reality in which travel restrictions made video-conferencing into the most widespread intra- and inter-company communication media, the manufacturing industry is reversing a global trend by bringing outsourced functions back into the company and unexpected events are causing an unusual shortage of raw materials that affects the delivery times of key components and stressing logistics systems to unsuspected limits. In brief, we are doing business in a turbulent environment where numerous companies with competitive strategies based on long-term contracts are now facing instability and machines designed and built to perform very specialised tasks no longer make sense in the production line.

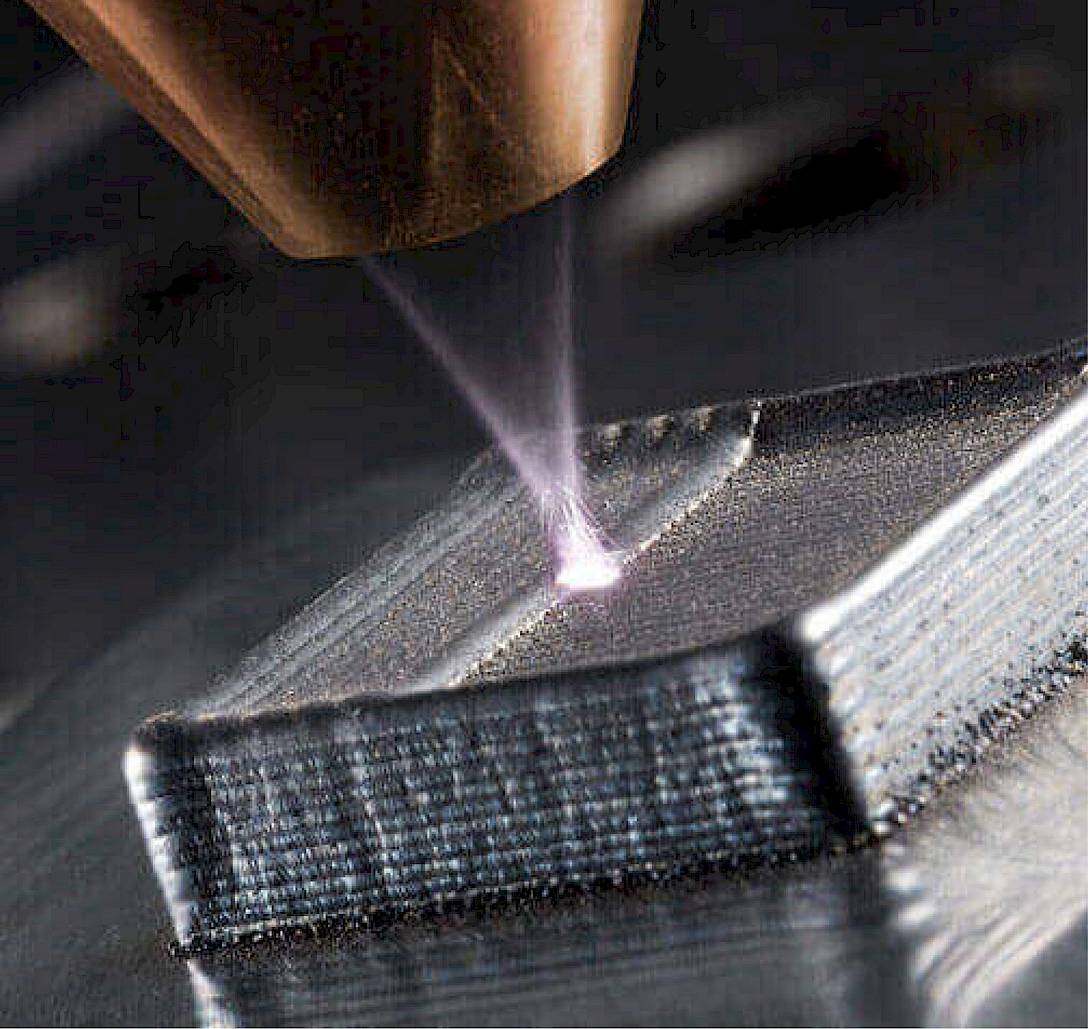

This new reality demands companies capable of adapting quickly to different jobs, which means that they must be provided with highly-versatile machining centres. Fortunately, the solution has a name:

ZVH MULTIPROCESS by IBARMIA, five-axis travelling-column machining centres with built-in lathe function.

When we mention the IBARMIA travelling-column platform we are talking about the program that embodies the very essence of IBARMIA as a project, the totally customer-oriented approach, which for a large parts hinges on the extremely flexible Z SERIES travelling-column platform that enables configuration of innumerable types of machine on the basis of the same structural components.

That's where our slogan “create your own machine" begins to make sense: highly-technical solutions with great added value 100% adapted to the specific needs of each customer/case.

In this respect, the basic features of our travelling-column centres could be summed up in two words: flexibility and versatility. The first enables us to implement the second: in other words, we design and manufacture the machine that best meets the demands of the current socio-economic context.

Do you want to read the full article?

Download the iNews

Do you want to read the full article?

Leave us your data to download the iNews where you will find many other articles related to the industry.

01

Download iNews

Download iNews