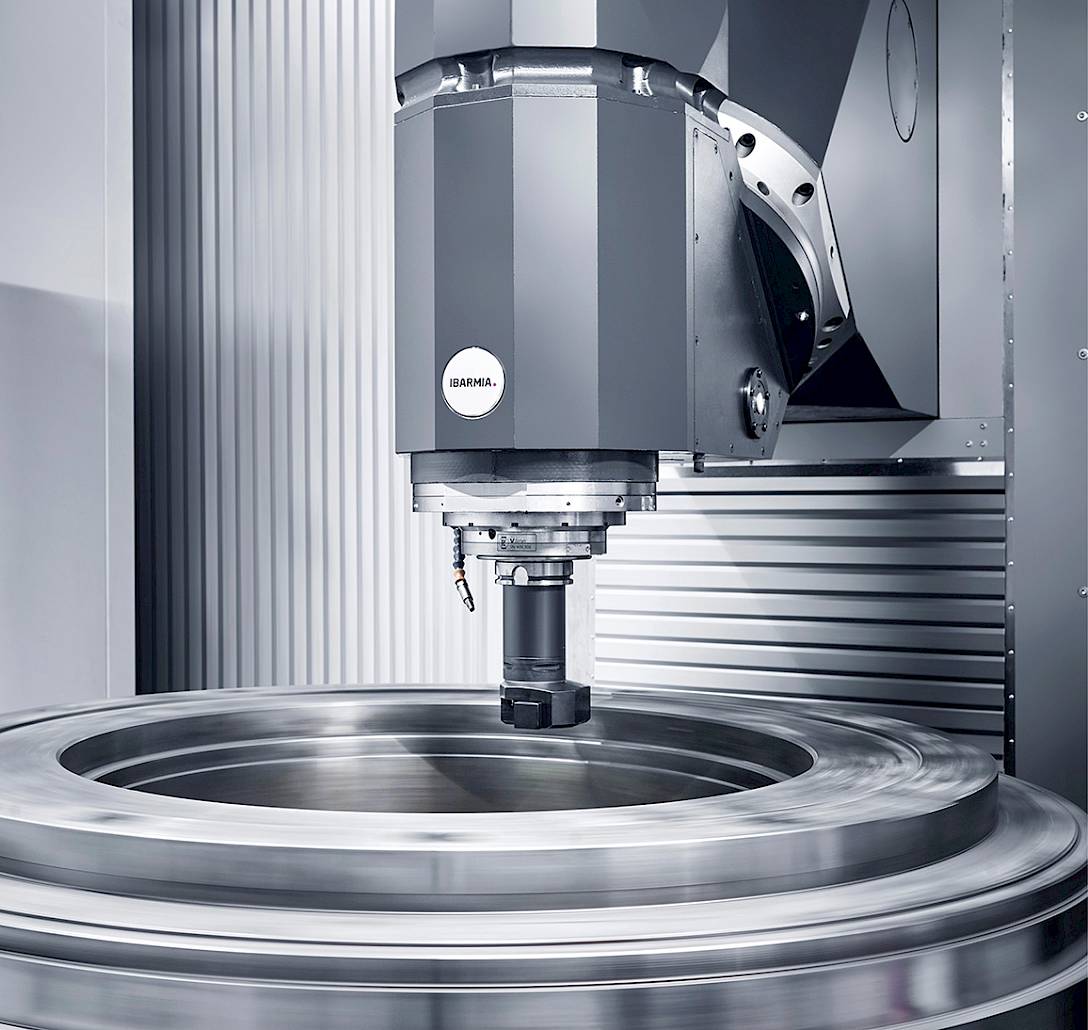

The new range of MULTIPROCESS turning centers can be configured to accommodate all the processes required in the complete machining of large circular parts: turning, milling, drilling, threading, boring and grinding.

New

CLD MULTIPROCESS_ INTEGRAL MACHINING OF LARGE CIRCULAR PARTS UP TO ø8500 mm IN ONE SET UP

The finishing operations in large circular parts are critical, reducing the number of set-ups avoiding errors is vital. The new MULTIPROCESS IBARMIA turning centers have been designed to respond to these real market needs.

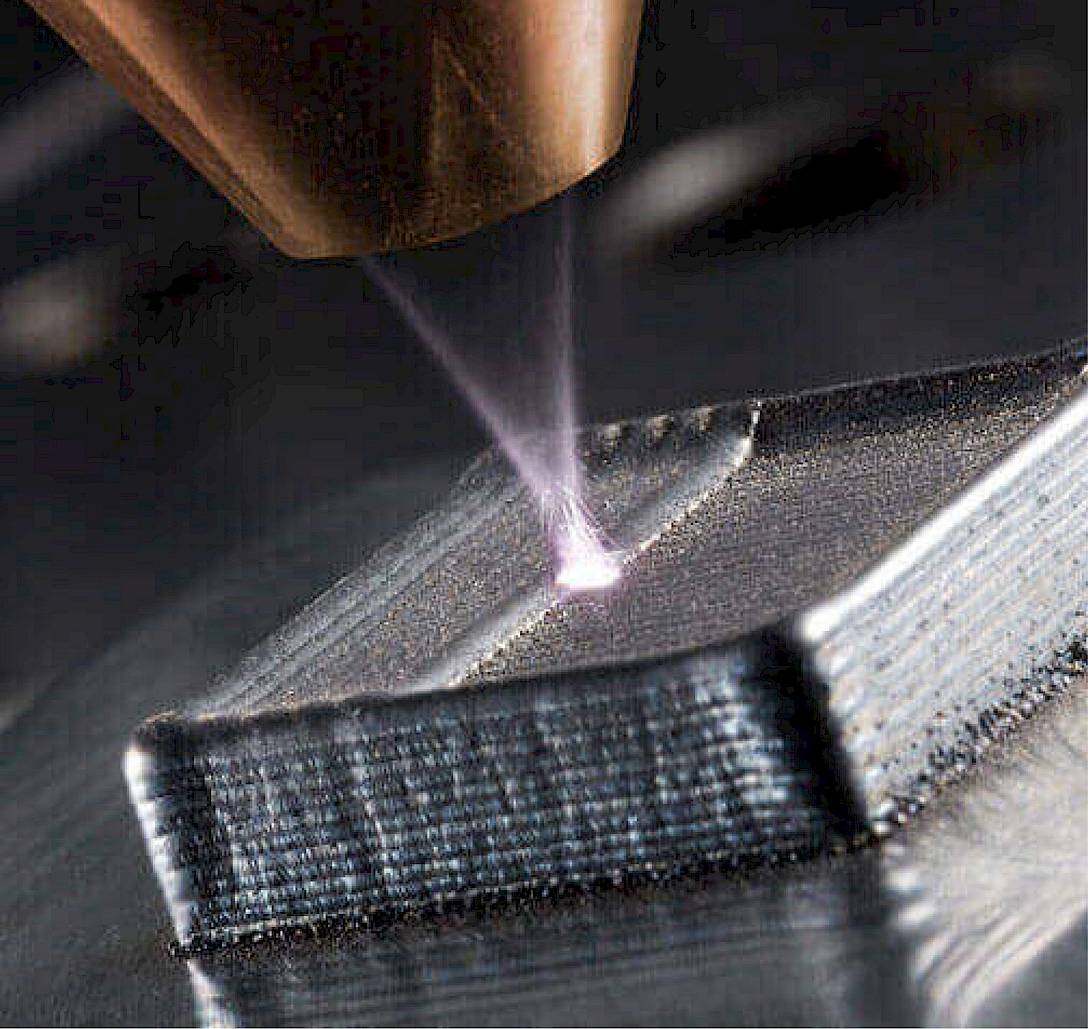

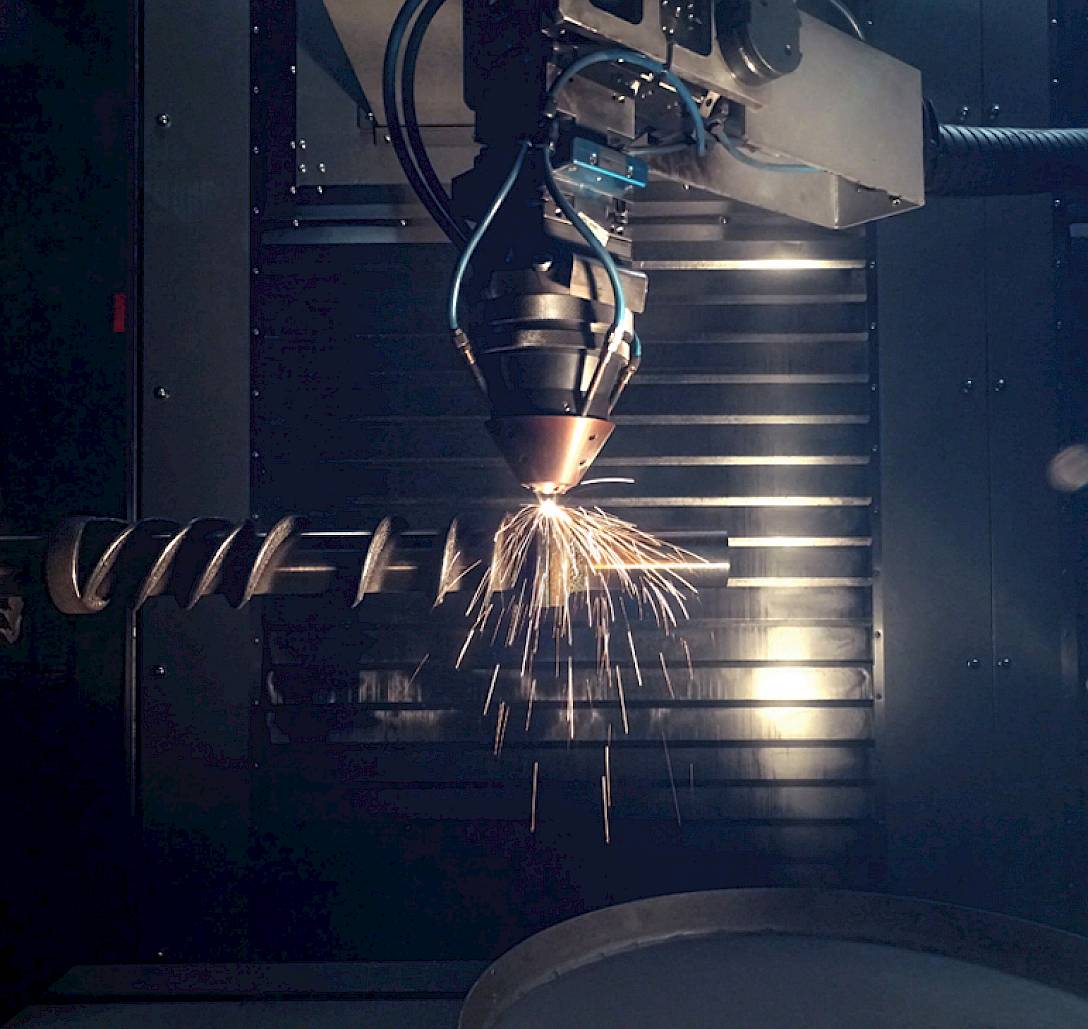

Turning, milling, drilling, threading and boring operations are brought together in a single machine which can also execute grinding operations for finishing processes, such as, for example, the raceways of large bearings. Although grinding is usually the usual finishing method chosen by manufacturers for these processes, IBARMIA also offers the possibility of using its Hard Turning capacity as a real alternative to this process.

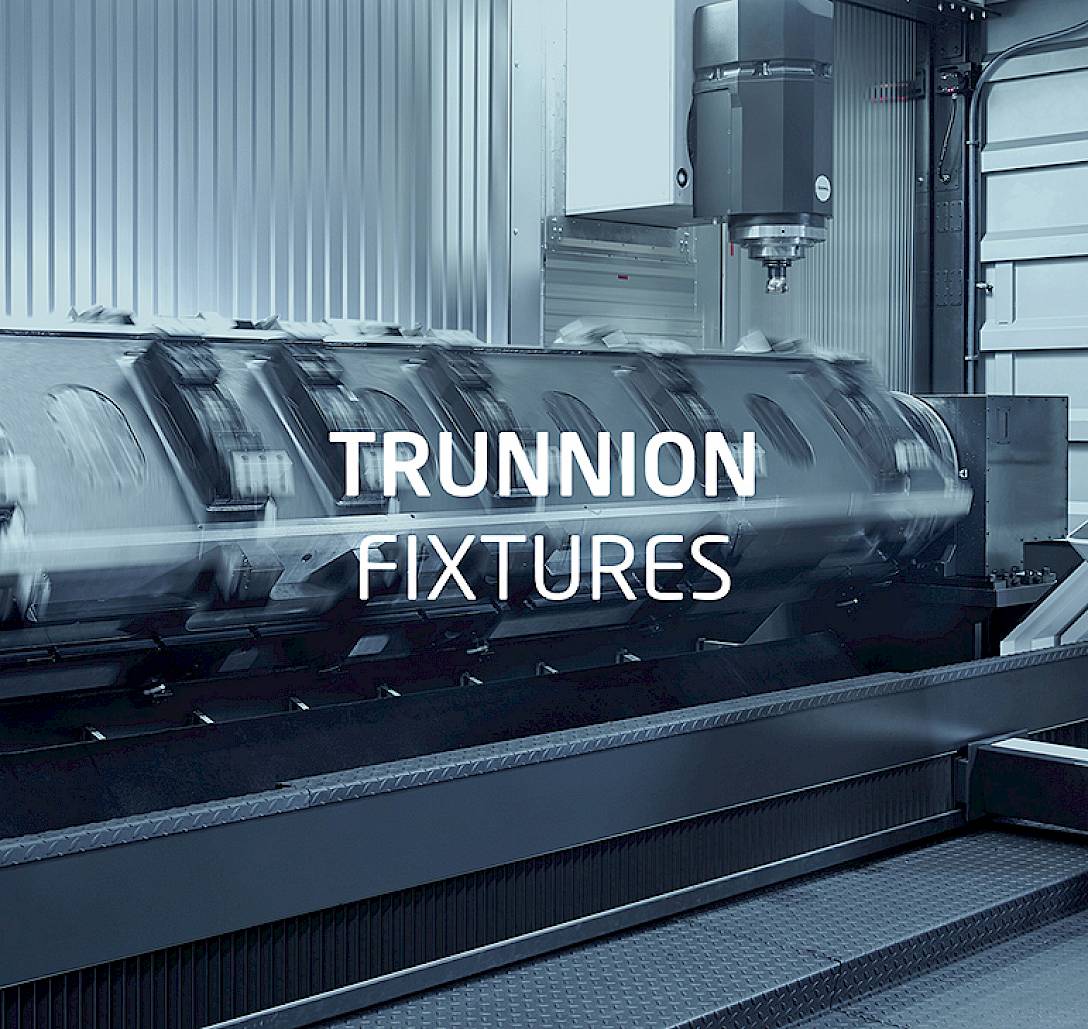

The variety of clamping fixtures, to facilitate the loading and unloading operations as well as the clamping and unclamping operations of the piece, give continuity to the successful line of clamping fixtures already developed for the drilling centers range and updated to the demands of turning and/or grinding operations.

The possibility to equippe the robust RAMs that the machine has (320×320 in the standard version and 400×400 as optional) with an automatic change of turrets and tool holders for turning gives the possibility to complete the most demanding machining process due to the capacity of the tool magazines that can be customized in each case.

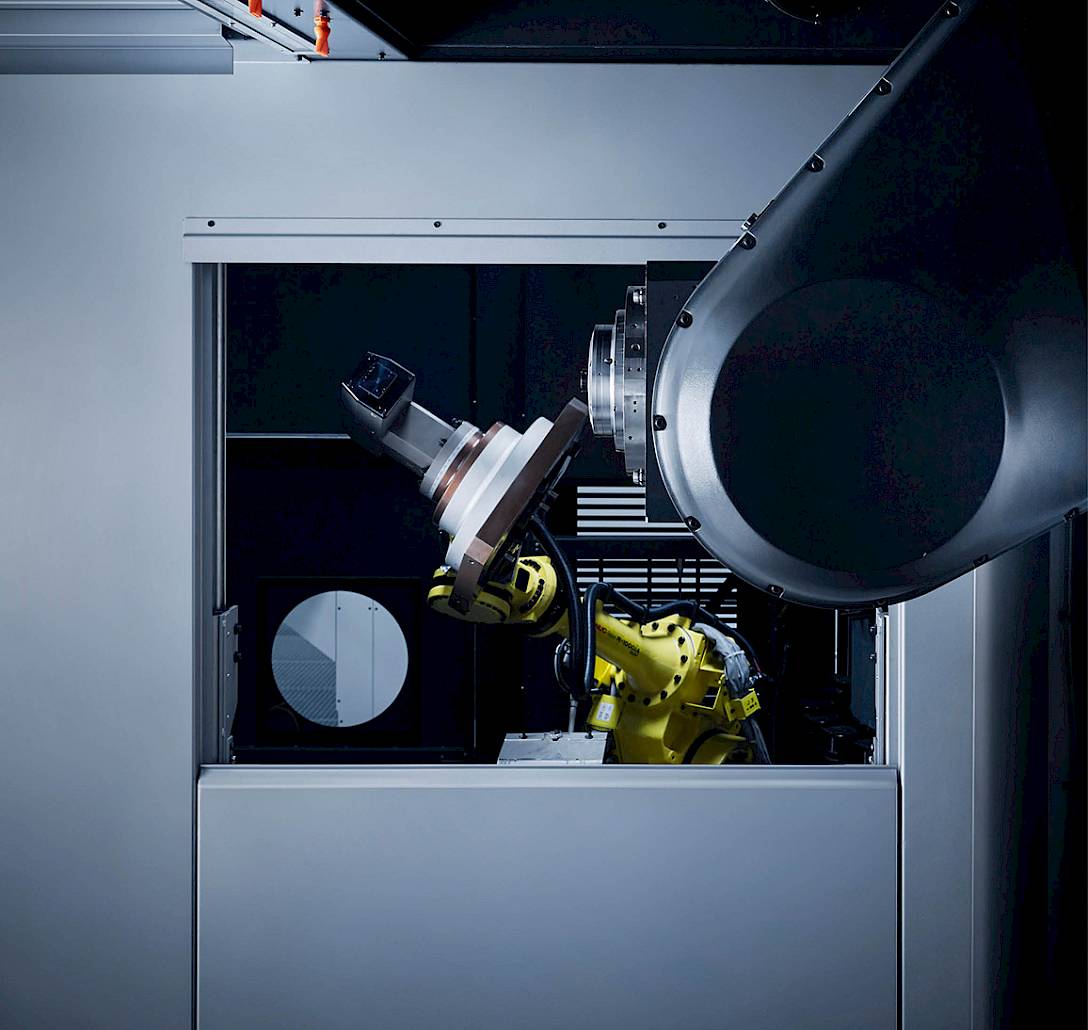

At the same time, the RAMs can be equipped with accessories that facilitate the execution of the rest of the machining operations, such as the Live Spindle integrated inside the RAM as a solution to vertical milling, drilling, threading or boring operations. Additionally, the live spindle can be used as a transmission for powerful angle heads (automatically interchangeable and hydraulically tied to the RAM, for horizontal drilling or threading operations) and with automatic 0-180º rotation (inside-outside or outside-inside operations), grinding straight heads (mainly used for grinding the raceways of large bearings) or fork heads (as a solution to surface grinding).

Large Bearings

IBARMIA has always been at the forefront in the design and manufacture of machining solutions for all types of large circular parts (mainly focused on the wind power sector), and in its extensive experience it has extensive knowledge and advisory capacity that make it the ideal technological partner for manufacturers of large circular parts such as large bearings.

Always close to its customers, IBARMIA is aware of the machining needs that are required when manufacturing large bearings. The evolution of its solutions, since its first foray into this sector more than two decades ago, today allows it to respond to all the manufacturing requirements associated with the machining. Machines that, maintaining the required turning capacity, are equipped with the rest of the necessary technologies to be able to complete the manufacturing process by reducing the total number of machines.

Do you want to read the full article?

Download the iNews

Do you want to read the full article?

Leave us your data to download the iNews where you will find many other articles related to the industry.

01

Download the iNews

Download the iNews