Ecology and Economy can go hand-in-hand, integrating “green” parameters into the design phase, as well as adopting measures that reduce the environmental impact, to achieve a perfect balance between both “eco” concepts.

New

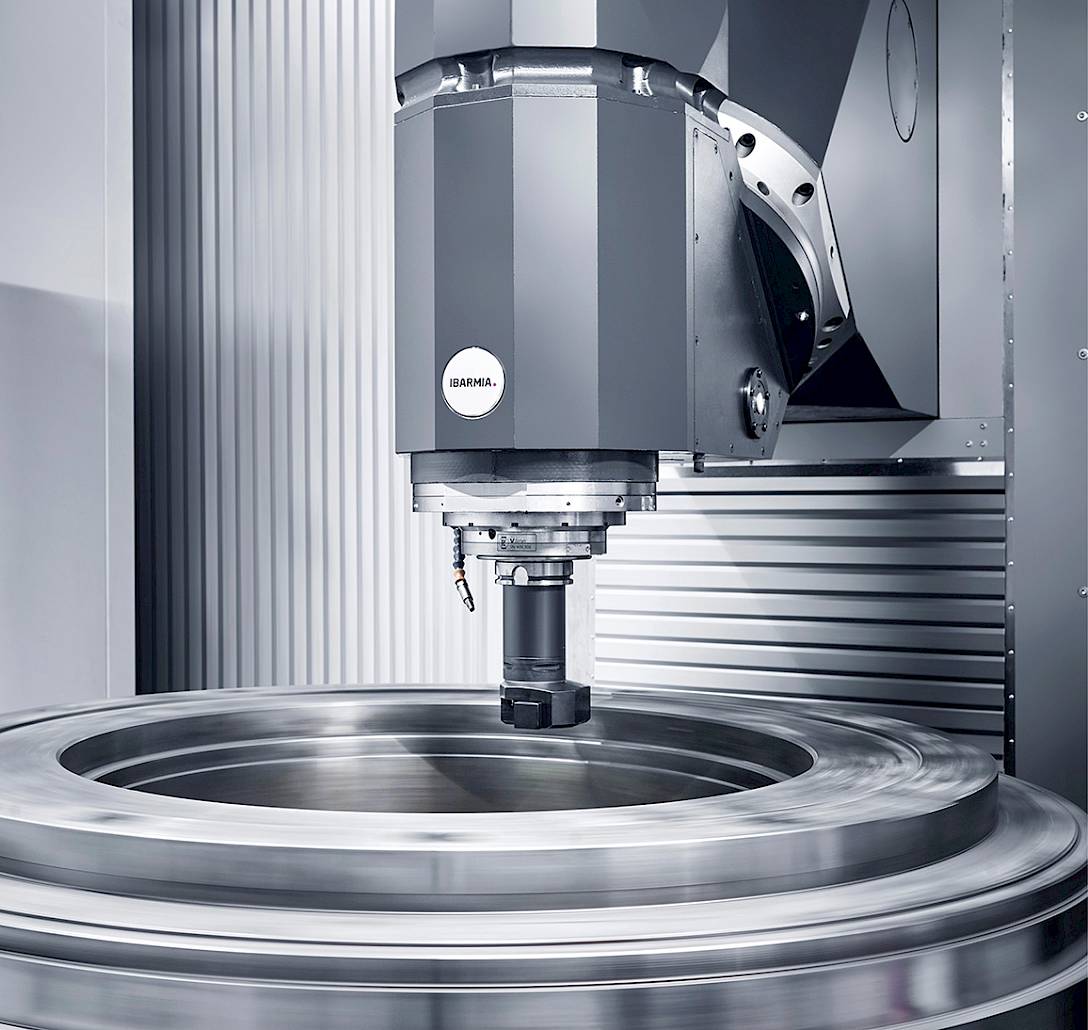

IBARMIA MACHINING CENTERS INTEGRAL MANUFACTURING ECO-CONCEPT

The Environmental aspect is becoming increasingly present in all areas of today’s society. Many products are designed taking into account their environmental impact during their lifespan, and Machine Tools are not exempt from this phenomenon. In this way, for several years now, IBARMIA has been taking measures to reduce the environmental impact of the products it manufactures. Obviously, considering the aspect of the environmental impact of a piece of equipment once it’s operational falls short in the analysis, since as manufacturers, we must also consider the impact that the manufacturing of each machine could have. So, in summary, considering the increasing demands in this field and, of course, the increasingly urgent need to make firm decisions in this regard simply because the future of the PLANET is at stake, IBARMIA decided to consider all these aspects as key elements of its General Strategy, integrating them throughout the value chain concerning product manufacturing, from the design phase, through manufacturing, to the definitive consideration of the environmental impact that each facility might have once installed at the customer’s site. This Comprehensive Strategy distinguishes two phases, which we detail below.

IBARMIA GREEN CONCEPT_

COMMITTED TO RESOURCE OPTIMIZATION AND MAXIMUM ENERGY EFFICIENCY OF THE MACHINES APPLIED TO THE MACHINE DESIGN PHASE.

APPLIED TO THE MACHINE DESIGN PHASE

• Development of thermo-design aspects during structural design of the machine, for a maximum optimization of the machine’s energy efficiency.

• Optimal sizing of the machine kinematic chain.

• Reconsidering the machine design in order to remove components from the moving parts, and move them to the fixed part.

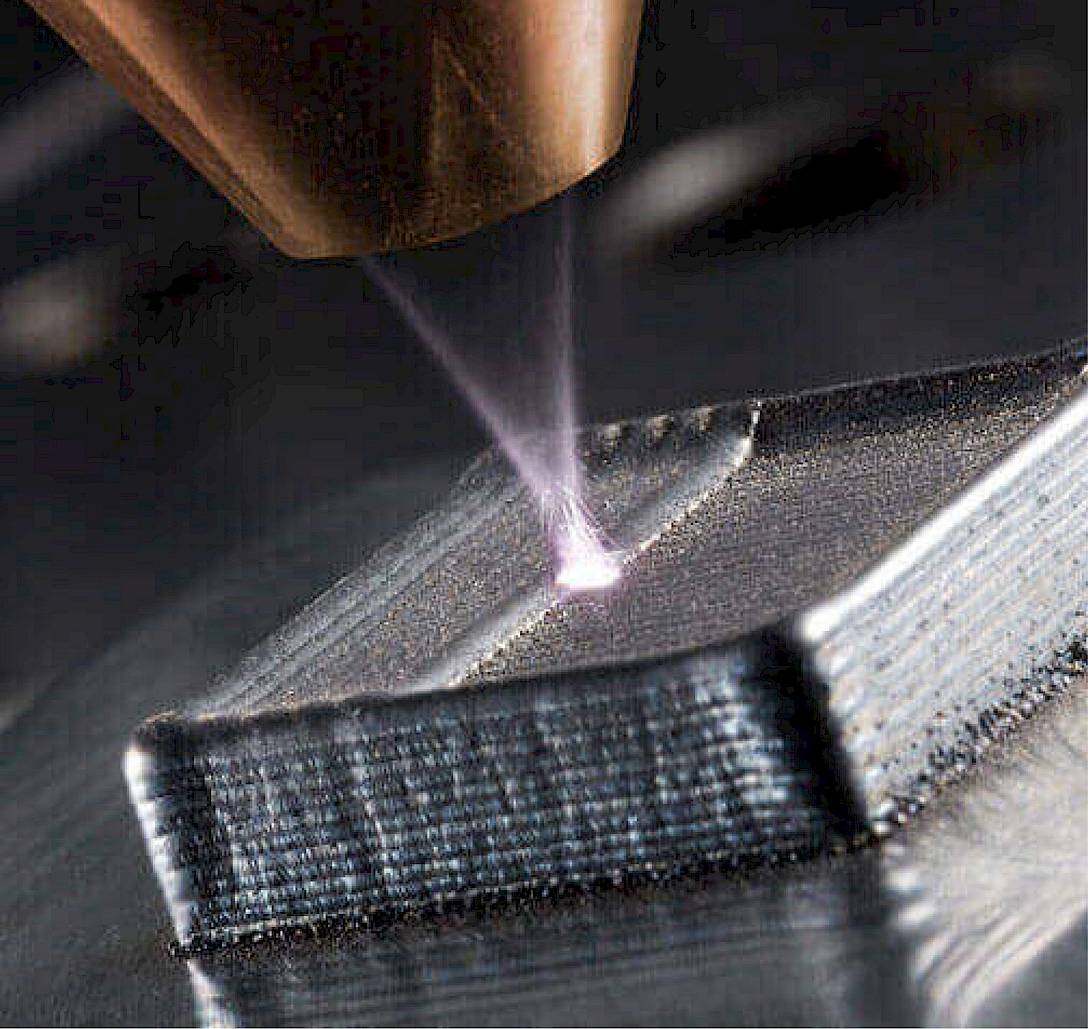

APPLIED TO THE MACHINE MANUFACTURIG PHASE

• Integrated and local machine manufacturing by using the right and necessary material and the source or manufacturing place of the components.

• 3D printers enable the use of lighter materials without losing machine performance.

APPLIED TO THE MACHINE PRE-OPERATIVE PHASE

Technological integration for a more efficient and optimal machine performance:

• Critical components monitoring in order to anticipate their failure.

• Technological cycles that help the machine to use only the necessary energy.

IBARMIA GREEN MACHINE_

MACHINES DESIGNED CONSIDERING THE ENVIRONMENTAL IMPACT THROUGHOUT THEIR ENTIRE LIFE CYCLE

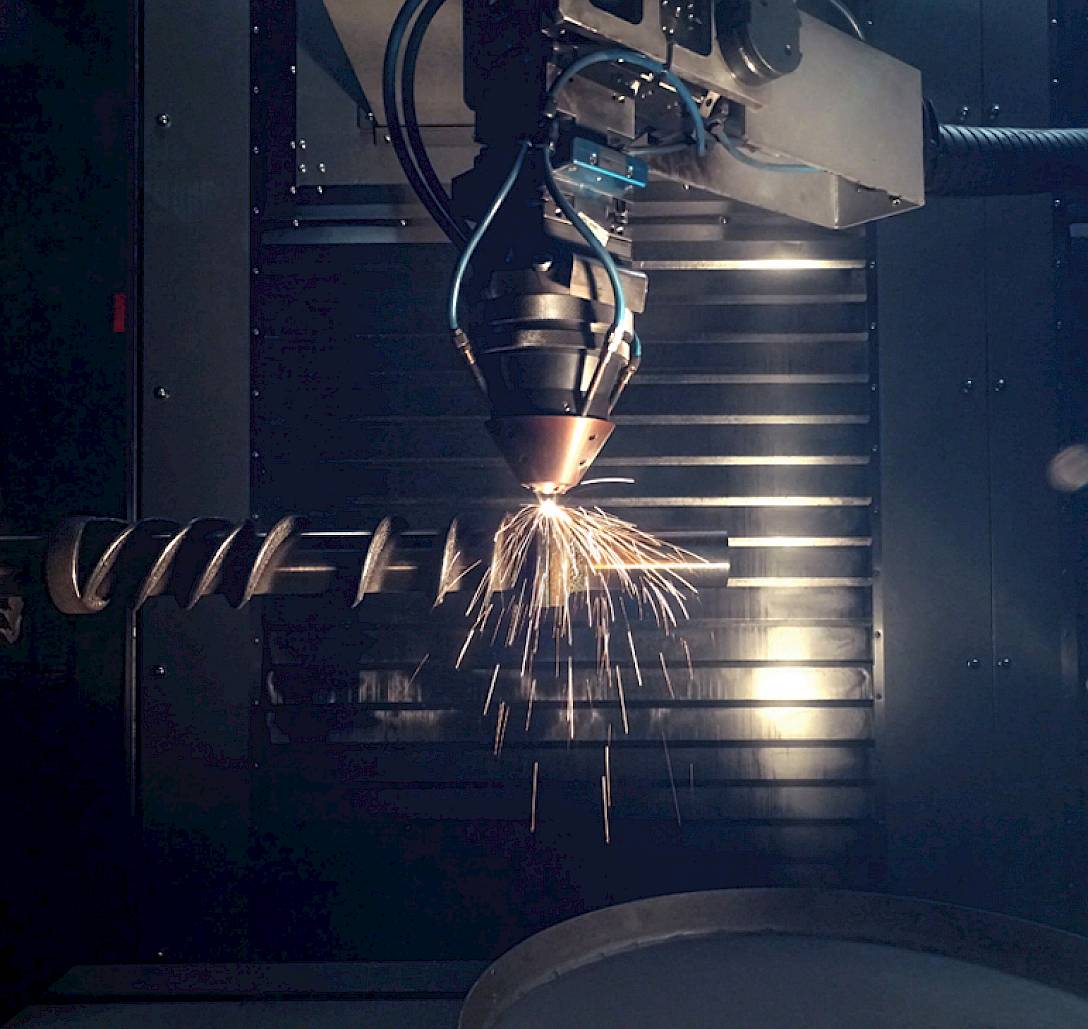

• MULTIPROCESS TECHNOLOGY

Various machines in one by using multitasking manufacturing, saving time, processes and energy.

• POWERFUL ELECTROSPINDLES With digital technology, to increase the cutting speed for a faster manufacturing, saving energy and limiting CO2 emissions.

• PRECISION PLUS CONCEPT Integral cooling measures to improve the thermal behaviour of the machine.

• MQL LUBRICATION

External / internal coolant frequency controlled by coolant hydraulic pumps.

• ADAPTIVE FEED CONTROL

• PID TECHNOLOGY COOLING UNITS

• LED LIGTHING / OIL SEPARATORS

• MACHINE STAND-BY AND AUTO POWER FUNCTIONS

• AIR BASED CHIP REMOVAL

• ZEROFOG OIL MIST COLLECTORS

In this way, the comprehensive approach to the aspects referred to as ‘eco’ implies considering them both in terms of the conception and manufacturing of the product itself and in the operational performance it can offer, minimizing to the maximum extent its future environmental impact during all the machine life cycle.

01