The company, which has sealed an agreement with TECNALIA China and the Chinese Railway Corporation, will invest over three million euros in six HAZITEK projects.

New

IBARMIA'S INNOVATIVE JOURNEY GAINS MOMENTUM ON ITS 70TH ANNIVERSARY

IBARMIA will surpass three million euros in investment across the six HAZITEK projects for 2023 in which it participates: four strategic ones (Accubask, Maqhia, Upscale, Confles) and two competitive ones (Saturno and Orkestra). This investment is in addition to a CDTI approval in July with over 300,000 euros in funding. The driving force behind this increase in R&D investment is IBARMIA's structural growth, which translates to more equipment and, consequently, enhanced responsiveness. This is why the company has been able to intensify its efforts in technological innovation, culminating in the submission of all six projects for the HAZITEK Program, a feat unprecedented in its history.

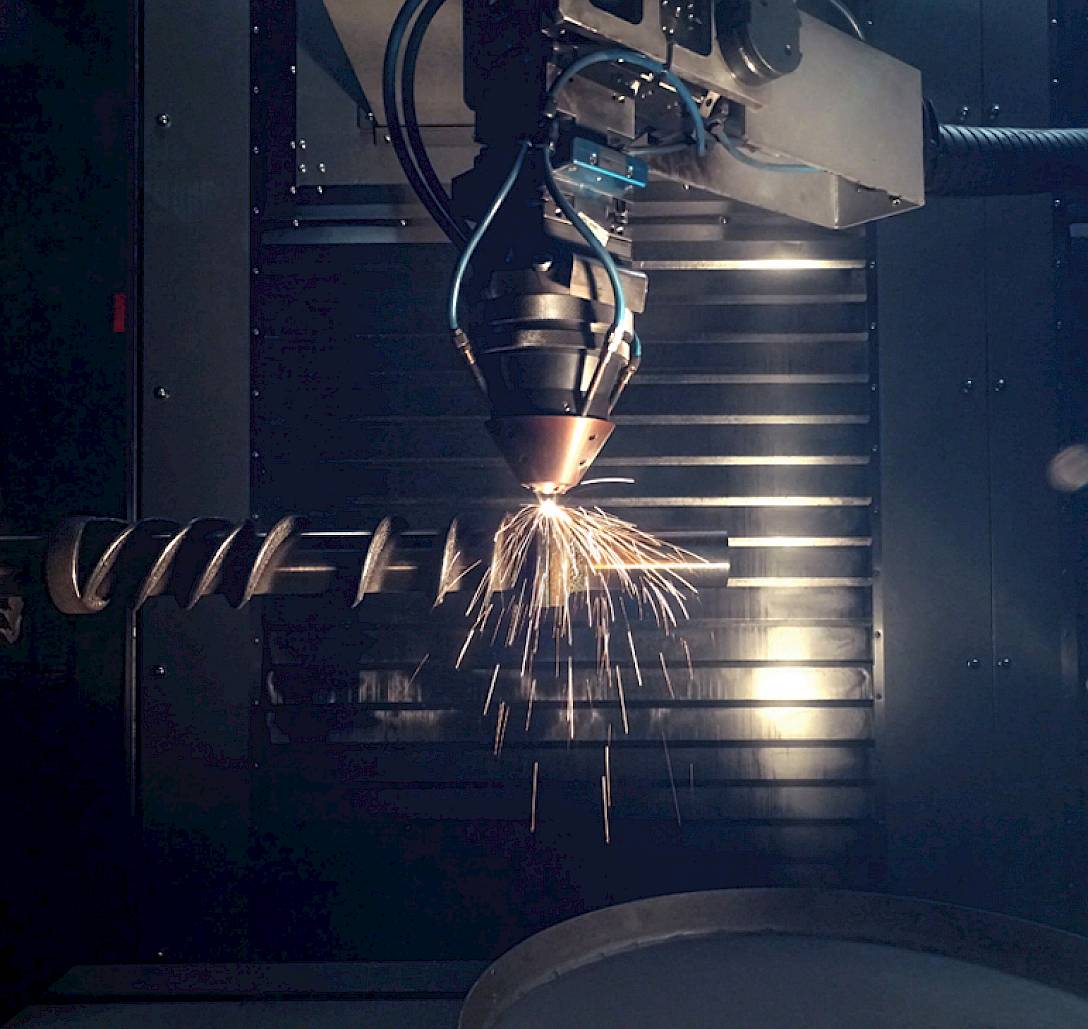

The significance of these ongoing projects lies in their direct alignment with new market demands, such as additive manufacturing with wire, controlled, flexible, and efficient machining of aeronautical materials, and a focus on high-value components in sectors like rail, allowing for the strategic acquisition of knowledge to diversify capacities and industrial sectors. For example, in the wire additive manufacturing sector, IBARMIA will collaborate with leading companies like Gestamp and the Chinese Railway Corporation on three projects, while, under Egile's leadership within the "Conflex" project for the aerospace sector, IBARMIA will invest over one million euros to explore new machine architectures that enhance performance and profitability.

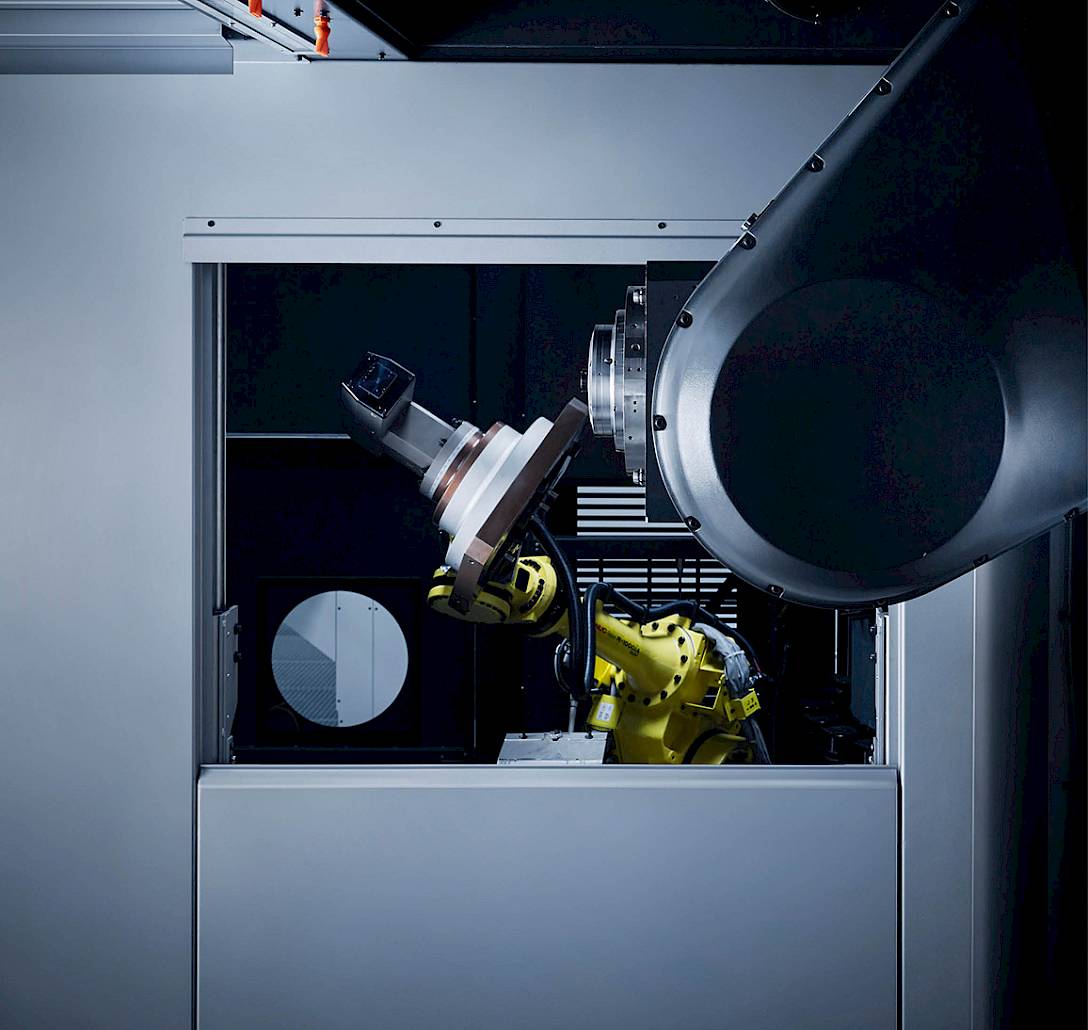

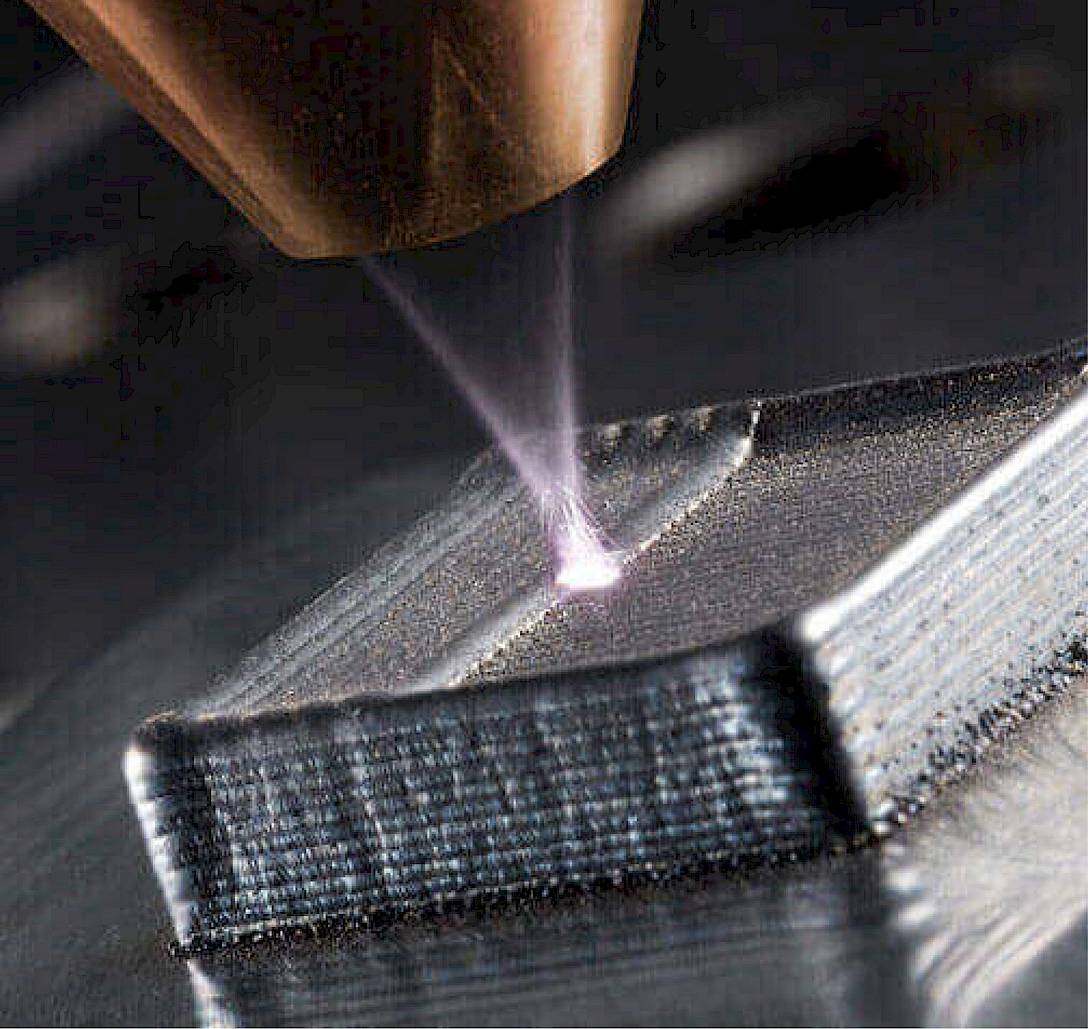

The substantial investment in the HAZITEK "Conflex" project, which includes participation from Egile Mechanics, Fagor Automation, Sariki, and Smart Process Management, is aimed at designing a new line of grinding machines that, while maintaining current precision and quality standards, increase productivity in NGV component machining processes and facilitate the use of standard grinding wheels. In additive manufacturing, IBARMIA has launched a plan to position itself in wire technology, after several years of progress in powder technology already offered in its catalog. The "Upscale" project, led by Gestamp, will focus on integrating wire technology into robots and/or machines, with an initial industrial milestone set for 2024. In the HAZITEK "Maqhia" project, they will work on cases to validate IBARMIA's technology in collaboration with Eibar Precision Casting, Optimus 3D, ABC, Juaristi and Delaser Global Solutions.

Finally, in the same field, they have entered into an agreement with TECNALIA China and the Chinese Railway Corporation, supported by CDTI, to create a hybrid process based on additive, machining, and artificial vision for the repair of high-value added railway components. This solution will overcome the thermal deformation issues that occur with traditional welding systems.

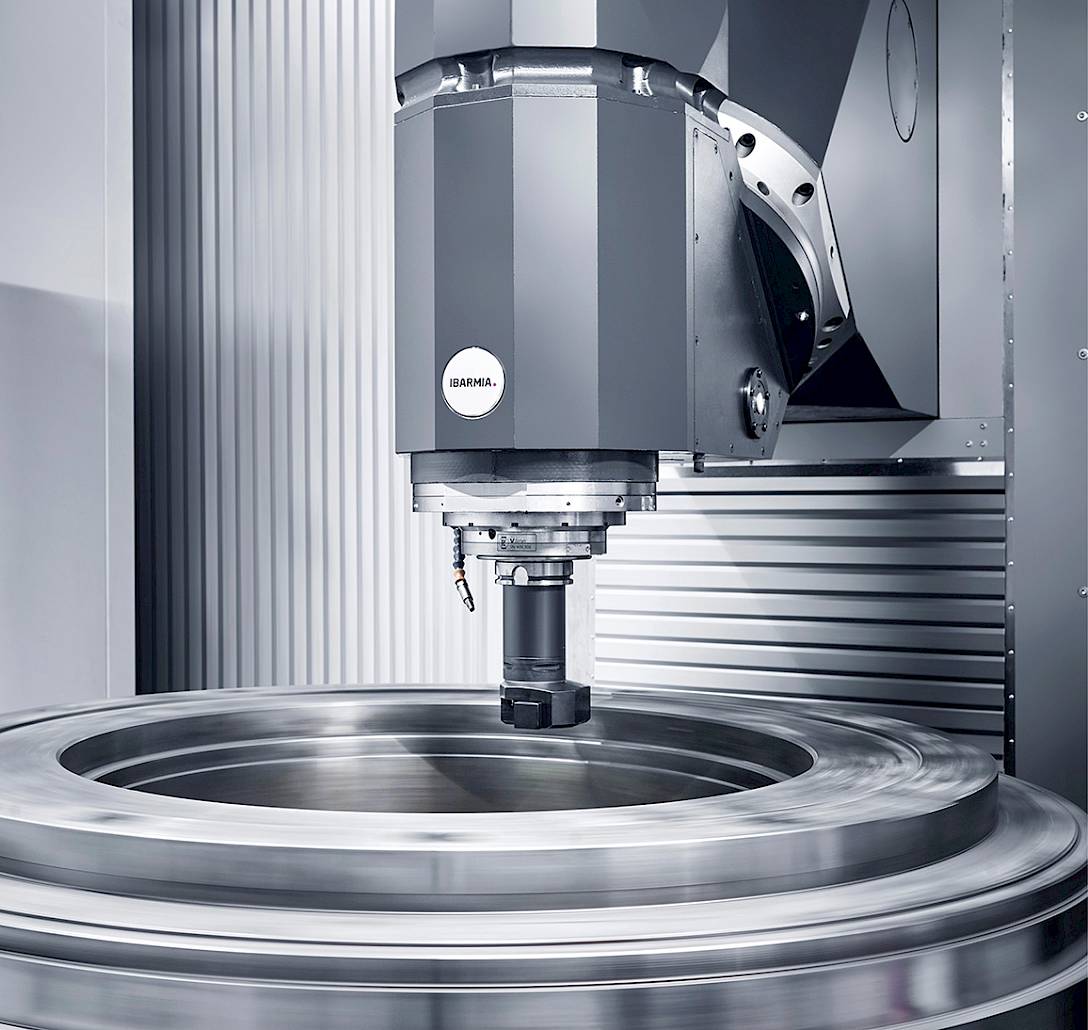

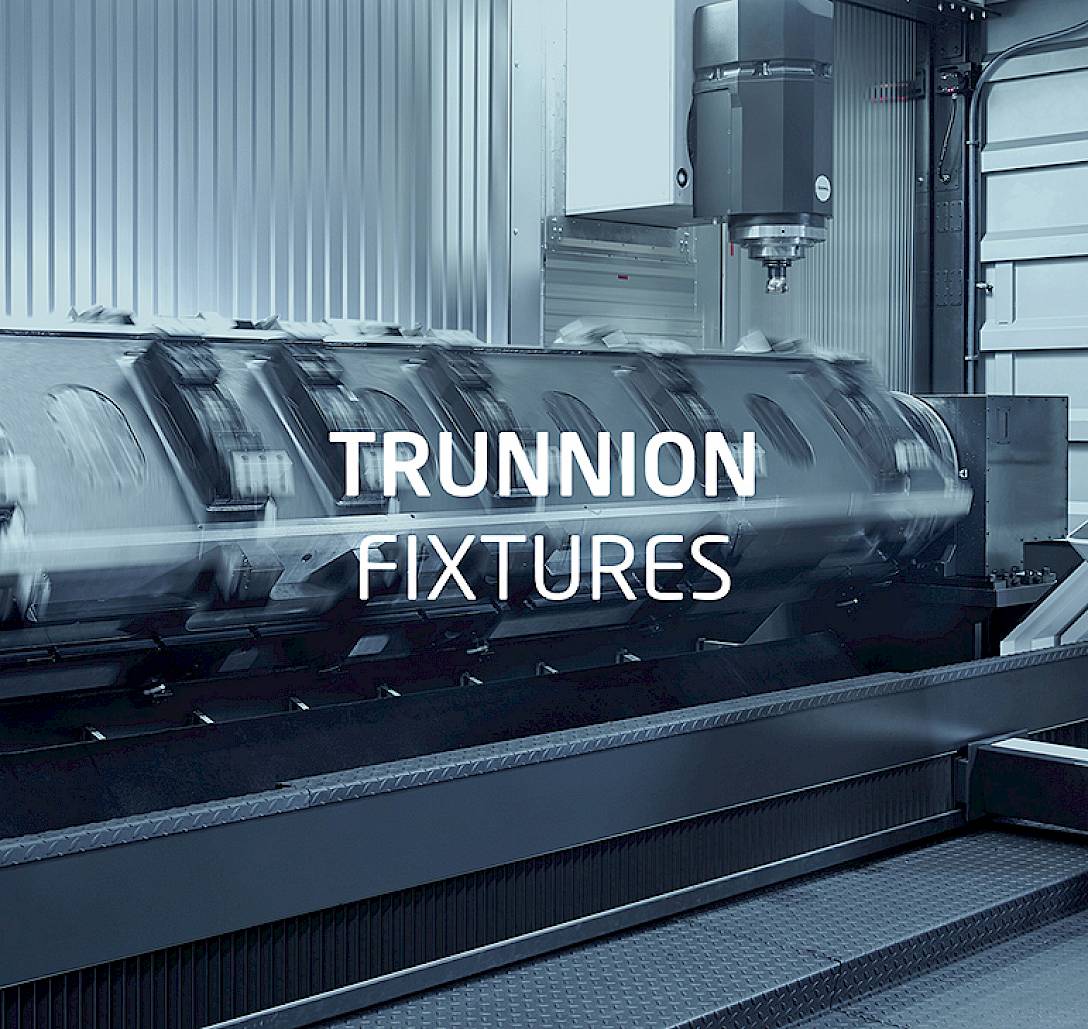

Noteworthy is the "Accubask" HAZITEK project, which centers on precision. In essence, it involves integrating measurement into the machine as an additional process. Collaborators in this project include Soraluce, Juaristi, Ona, Danobat, Zayer, AFM, Fagor Automation, Maier, Gaindu, and Macarbox. In the competitive HAZITEK sphere, and in continuation of projects presented in 2022, IBARMIA will finalize the "Saturno" and "Orkestra" plans. The former is focused on creating a machining architecture for offshore components (flanges and bearings) of up to 12 meters in diameter, while the latter aims to standardize communication protocols to shorten automation lead times for different systems existing in the market, as requested by clients.

01