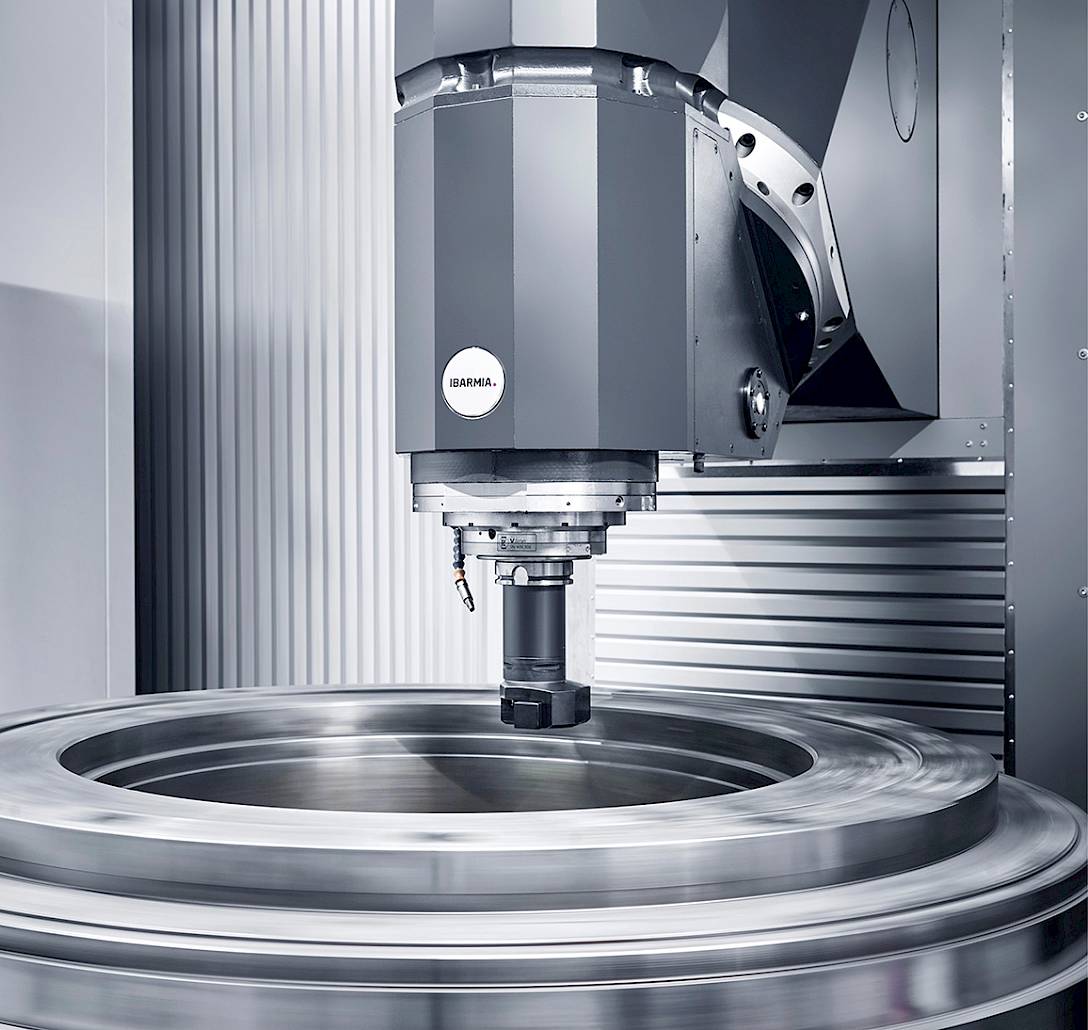

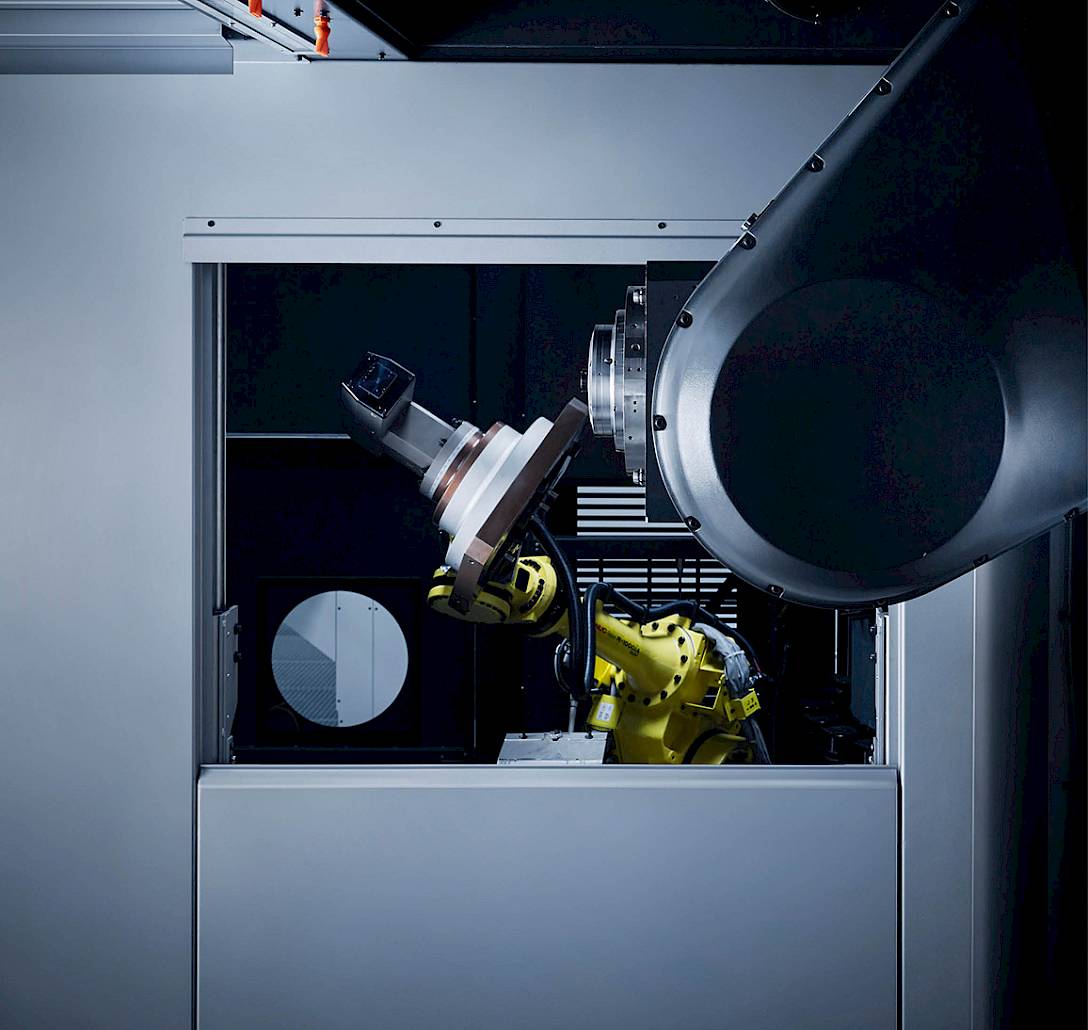

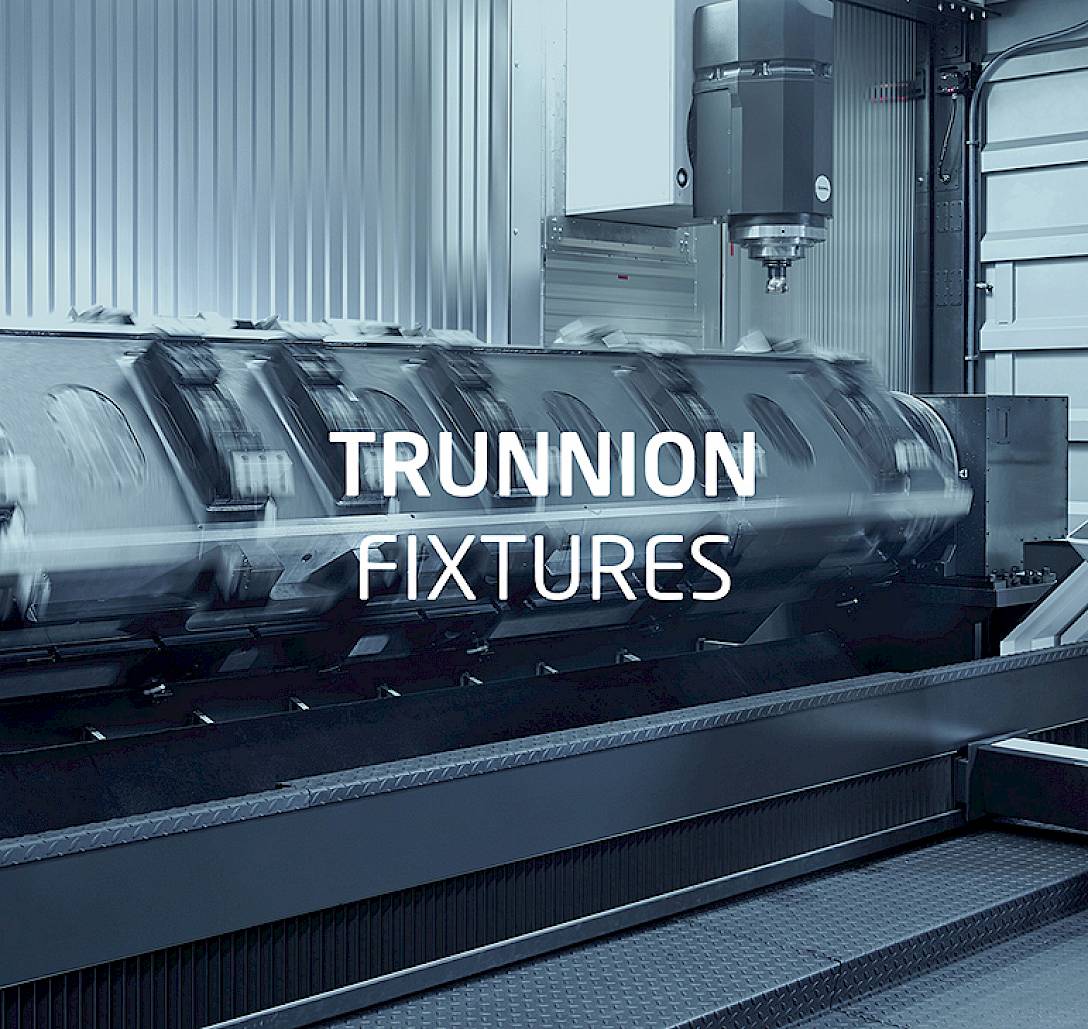

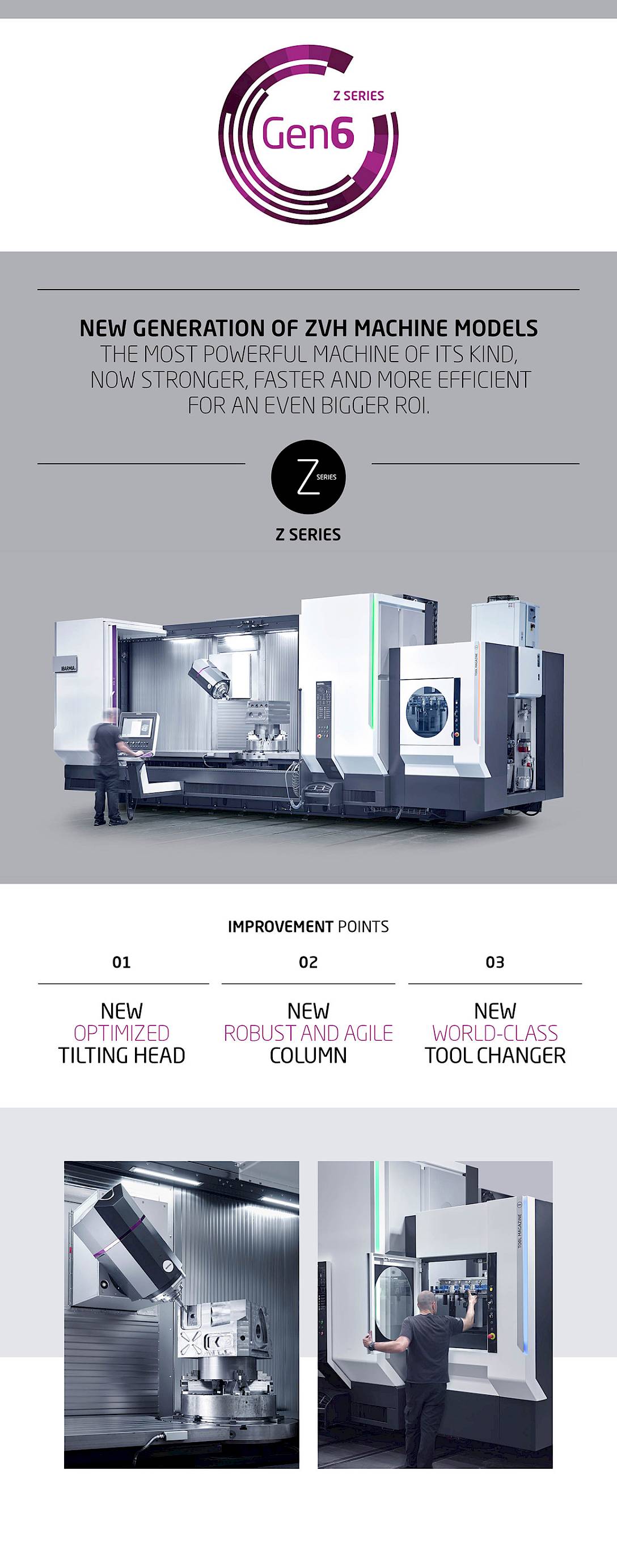

For the sixth generation of Z SERIES Moving Column Machining Centers, IBARMIA has revised the design of the machine and the result is a significant improvement in working space, dynamics, tool change and ergonomics.

New

NEW GENERATION OF Z SERIES-ZVH MOVING COLUMN MACHINING CENTERS

The most important improvement of these new ZVH MULTIPROCESS and ZVH EXTREME machining centers is the 20% larger work envelope for 5-axis machining. IBARMIA engineers have achieved this by reducing the distance between the spindle nose and the swivel axis of the spindle. Instead of 375 mm, it is now only 300 mm on the new generation of machining centers. If the spindle is positioned horizontally, the spindle nose can be lowered to 250 mm above the work table, compared to 375 mm in the previous generation of the Z SERIES. As a result, for example, for the versions with an X axis of 3000 mm, this means a maximum workpiece length of 2400 mm instead of the previous 2250 mm, and for the workpiece height, 800 mm is now possible instead of the previous 725 mm. At the same time, the maximum workpiece weight of up to 2000 kg/m² remains as high as users appreciate in IBARMIA.

Magazine holds up to 60 tools

Another important change can be found in the tool magazine: It is now located to the side of the machining area instead of behind the moving column. As a result, the tool magazine can optionally hold up to 60 tools - 50% more than the previous generation. For even more tools, IBARMIA offers the INDUNOOR M magazine.

It is also possible to exchange the tools in the magazine even during machining time. Moreover, during the tool change, the automatic tool changer no longer intrudes into the interference circuit of the machine.

Dynamics of the moving column increased

The changed position of the tool magazine enables even more improvements for the new generation of machining centers. The moving column is stiffer and moves more dynamically. The additional acceleration of approximately 0.5 m/s² represents an advance of 30%.

The new generation of ZVH MULTIPROCESS and ZVH EXTREME machining centers offers further advantages in terms of ease of maintenance and ergonomics. For example, pneumatics and hydraulics are combined in one place and easily accessible through a door. IBARMIA has also lowered the table height by 50 mm, which improves ergonomics for operators.

Reduced footprint facilitates transport

In addition to these improvements, the footprint has been reduced. The width of the machining center has been reduced by 500 mm. This not only simplifies installation in the production hall, but above all transport: a special heavy-duty transporter is no longer required to bring the machining center to its destination.

At the same time, with the new generation IBARMIA has taken the opportunity to standardize the Z SERIES machining centers to a greater extent. This means faster construction and cost reductions, which in turn make the machines more economically interesting for customers.

01

Download the catalogue

Download the catalogue