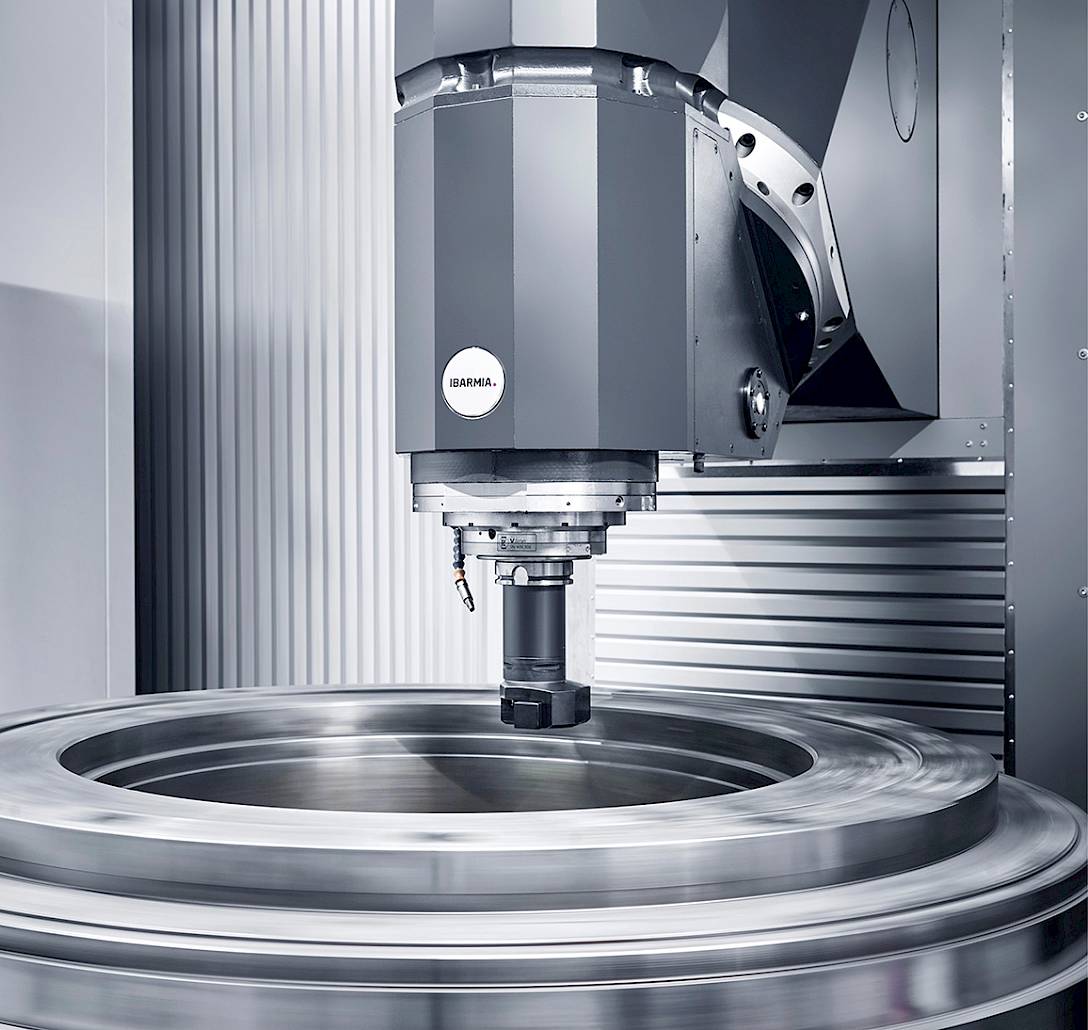

For many years, here at IBARMIA we have been working with this concept, which is perfectly integrated into our Z SERIES program

New

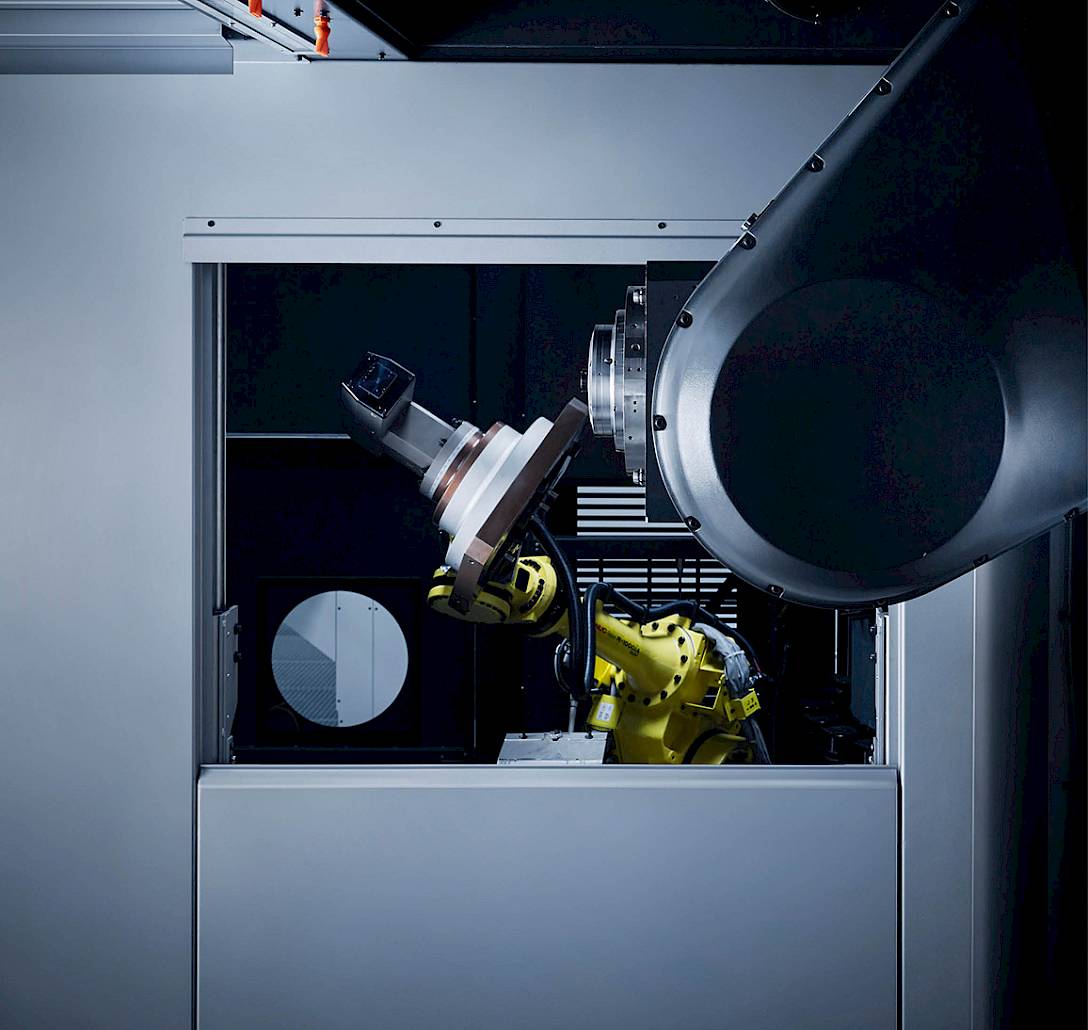

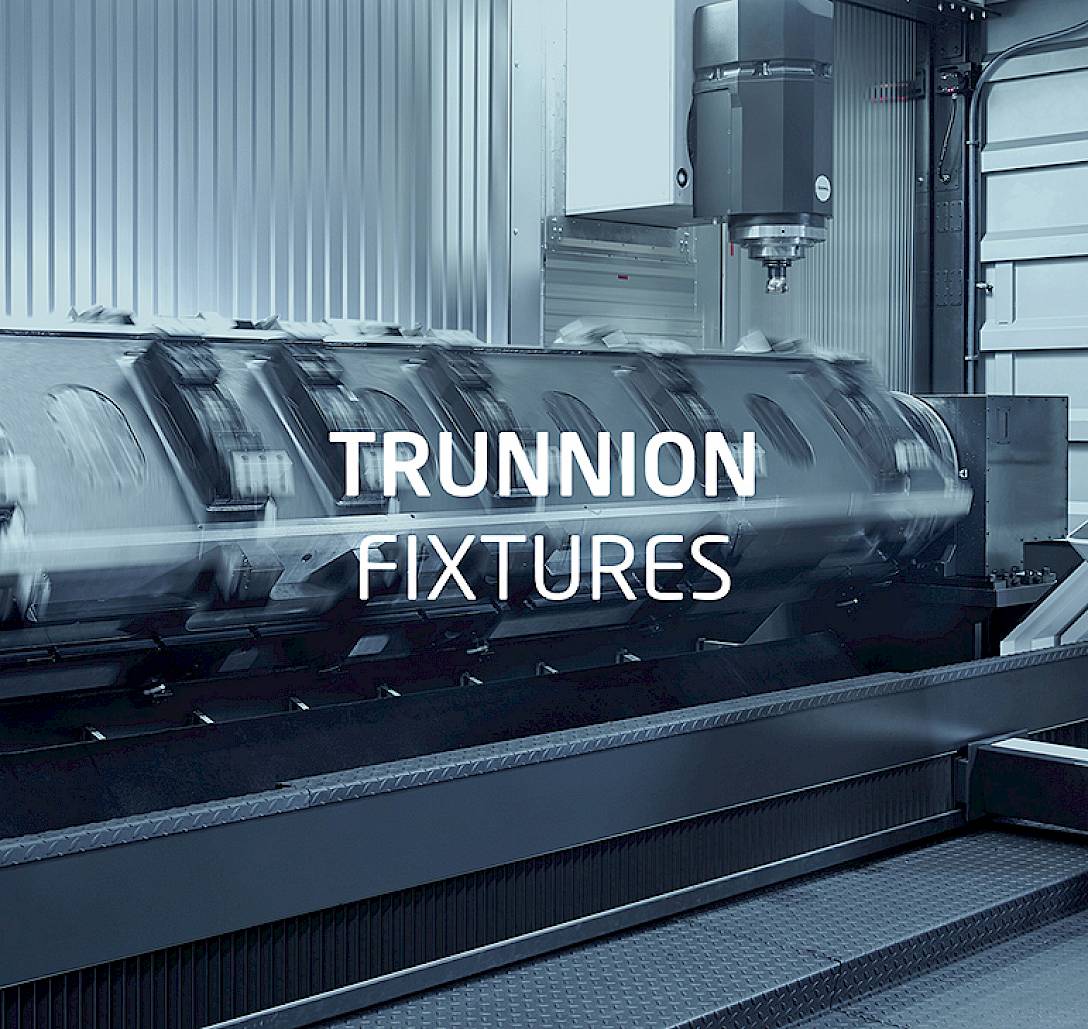

TRUNNION; A CUSTOM SOLUTION FOR OUR MOVING COLUMN MACHINES

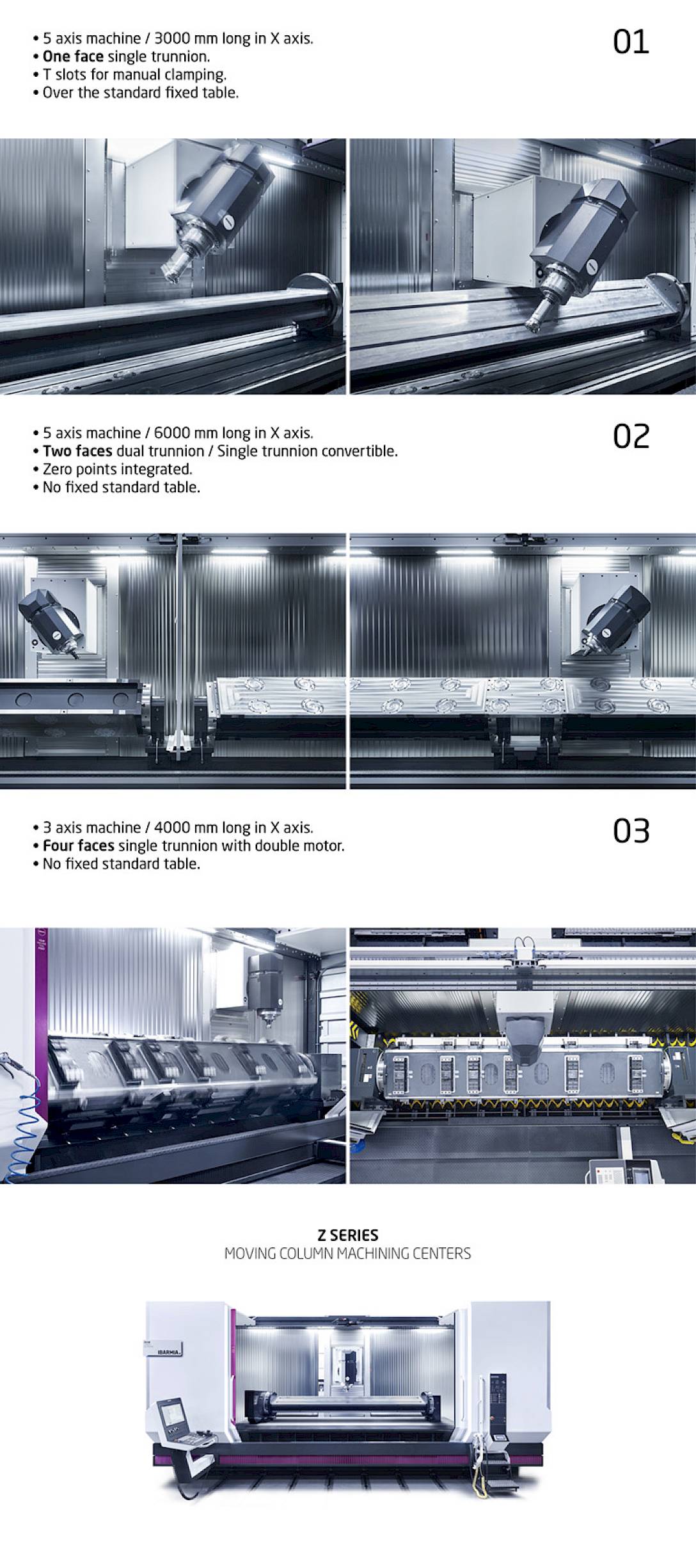

The trunnion consists of a fixture that turns around an axis (A). The rotation is made by using a rotary table with a support (motor-support), or 2 rotary tables (double motor system). Thanks to this trunnion fixture, at Ibarmia we offer the possibility of machining 1, 2 or 4 faces, with a smooth surface with clamping holes, T-slots, and the possibility of integrating zero points in the tooling, which facilitates the automation of the part change.

Many machines and applications have been approached, from trunnions mounted on the fixed table to machines with no table and a design adapted to the tooling. Depending on the transversal stroke of the machine, one or two trunnion tools can be mounted for pendulum cycle work. It also includes the possibility of integrating a plate between the two central rotary tables, connecting the fixtures on both sides to change from a double to a single workstation.

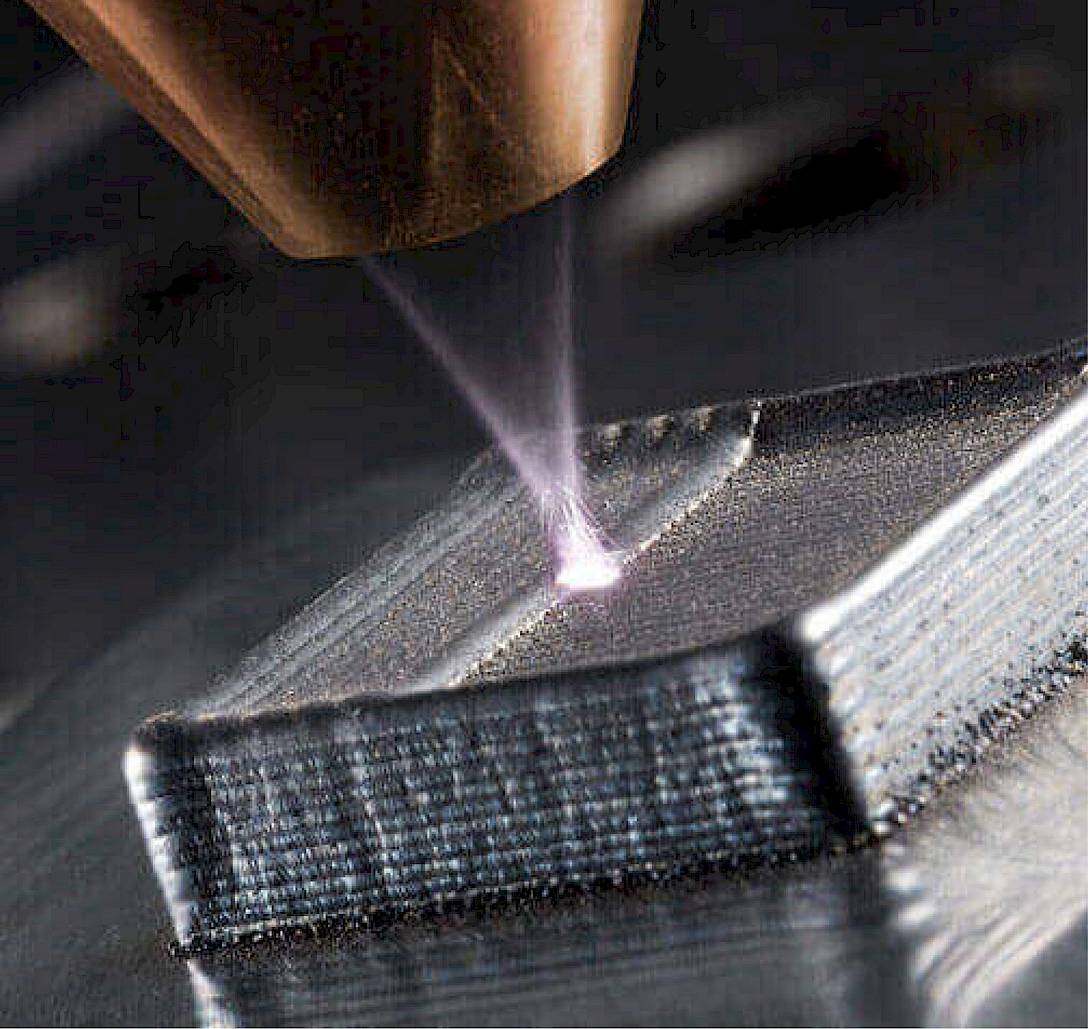

The biggest challenge in this type of developments is the request for precision. In order to meet this requirement, we manufacture the tooling providing a solution to the problem from the initial design stage, starting with the finite element calculation to have complete control over the flexion of the part, up to the definition of the geometric tolerances that must be included in the machining drawing.

In short, we are talking about a concept tailored to our Z SERIES moving column models in which the longitudinal travel is the key feature, introducing an added rotary axis for the machining of long and extra-long parts that do not require large transversal stroke.

SUBSCRIBE TO OUR NEWSLETTER

Subscribe to our newsletter to receive more content like this.

SUBSCRIBE

SUBSCRIBE

SUBSCRIBE TO OUR NEWSLETTER

01