Precision, automation, digitization and applied AI to drive high-value-added machining

New

IBARMIA consolidates its commitment to R&D in 2025 with nine key projects

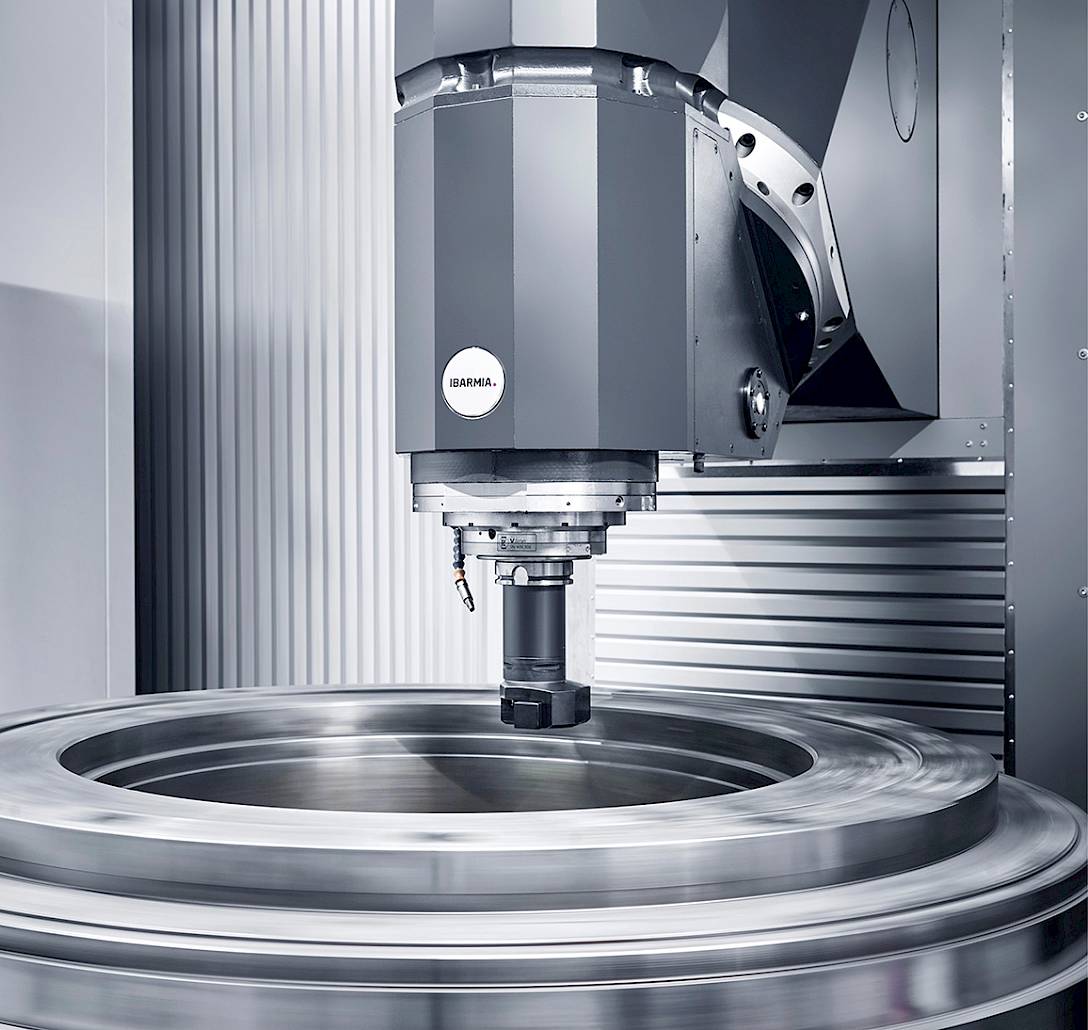

In 2025, IBARMIA has reinforced its technological leadership through a new portfolio of R&D projects aimed at increasing productivity, sustainability and process robustness in advanced machining applications. In line with our collaborative innovation strategy, these initiatives range from new thermal machine architectures to gear manufacturing, process virtualization and artificial intelligence applied to the plant.

R&D projects developed during 2025

Among the projects that have marked the fiscal year, the following stand out:

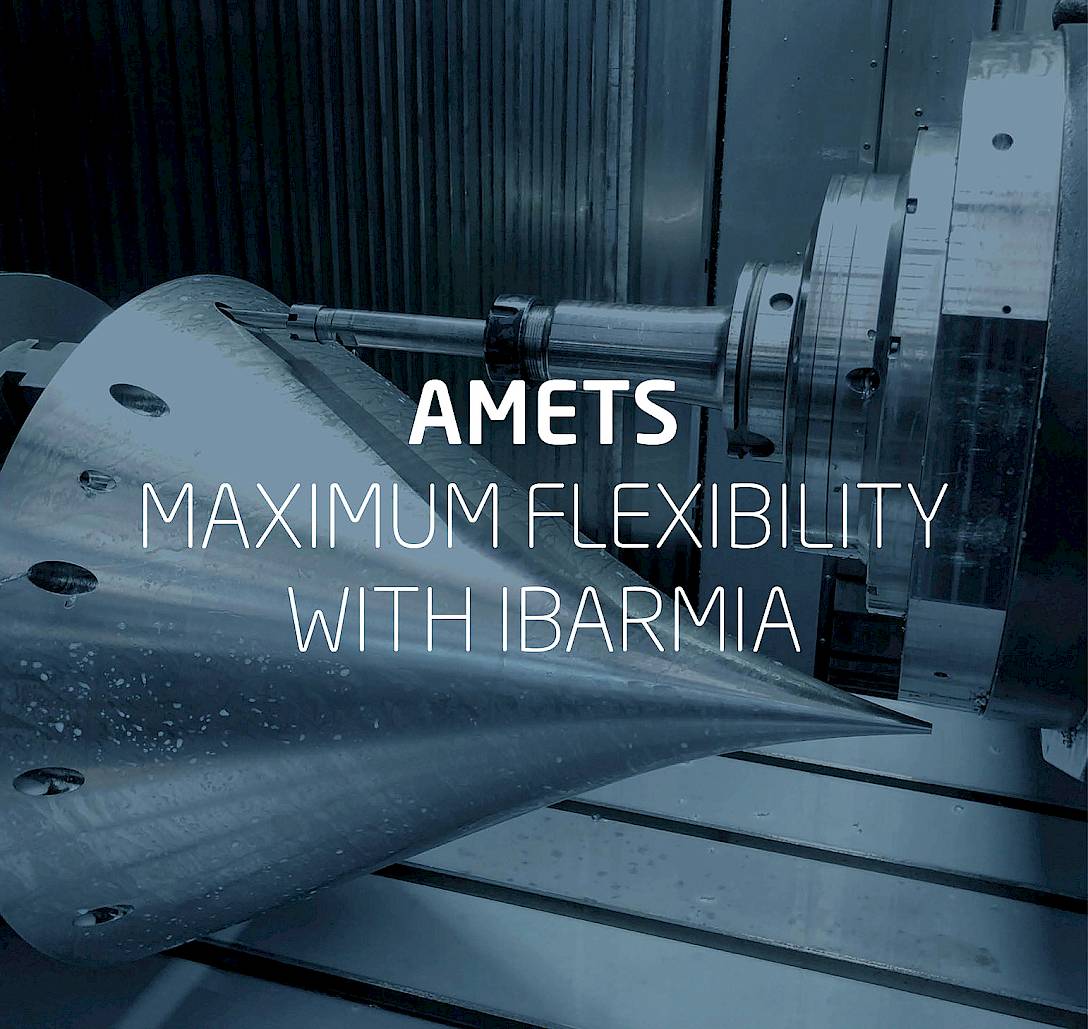

UPSCALE: research and development of technologies, processes and simulation models to optimize the integration of subcomponents in safer, more circular, accessible and lighter vehicles.

ACCUBASK: precision engineering and advanced metrology technologies to advance towards more intelligent, efficient and "zero-defect" production systems.

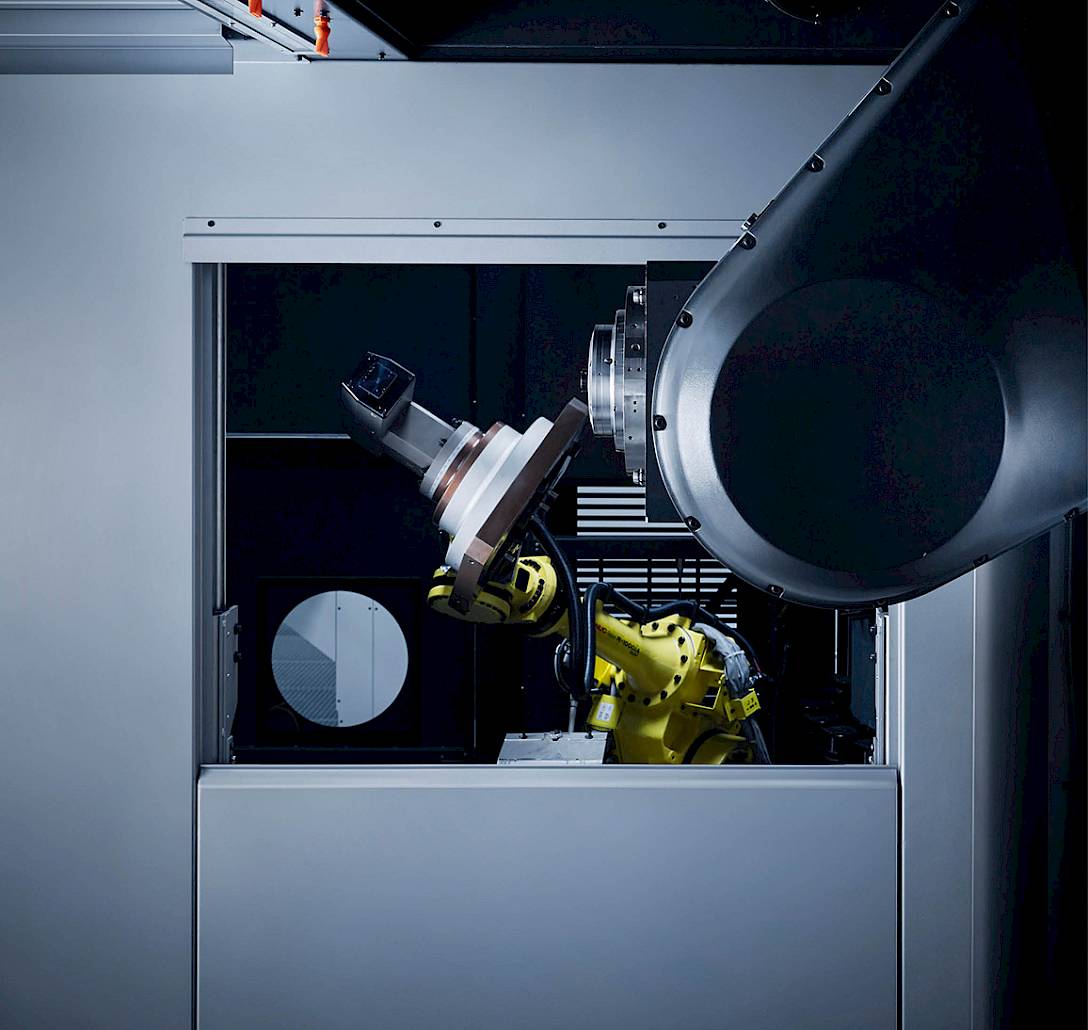

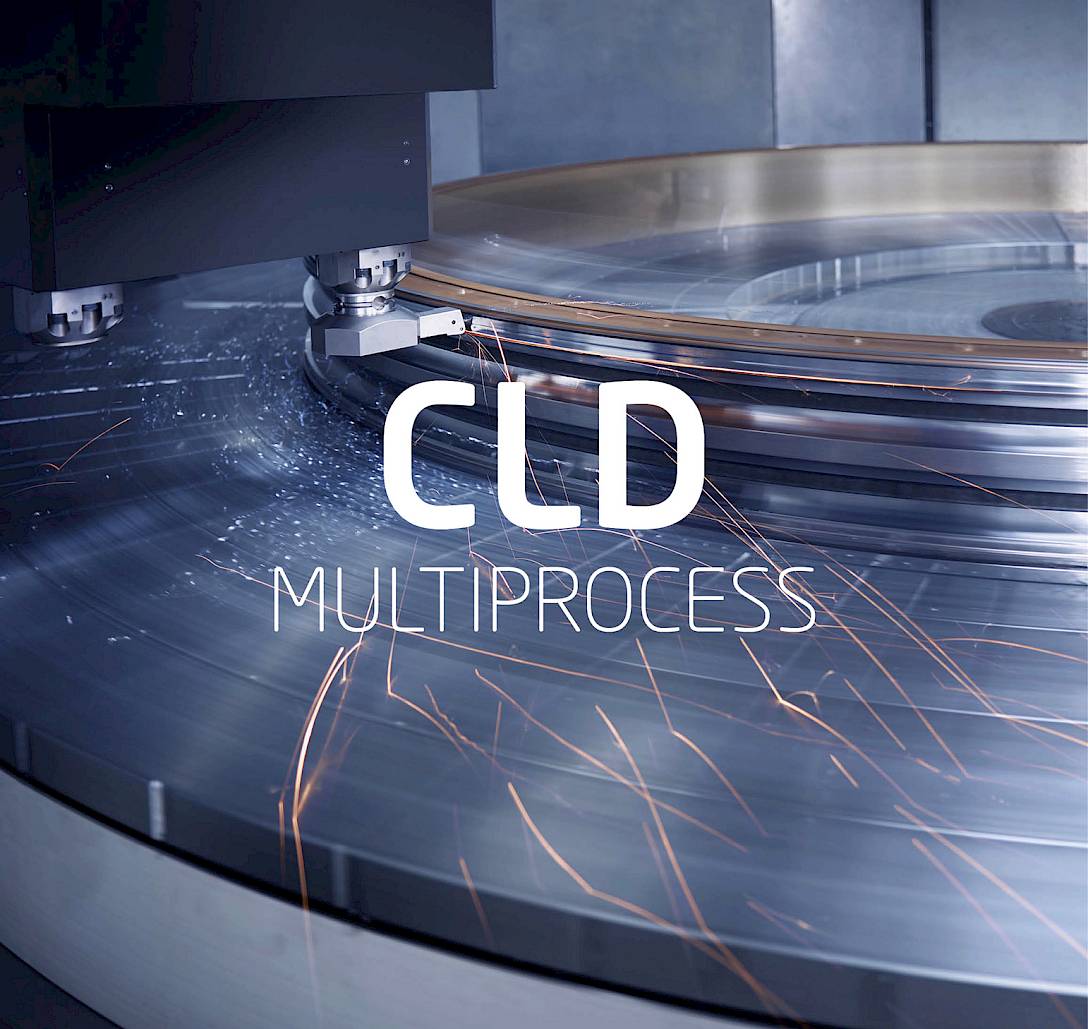

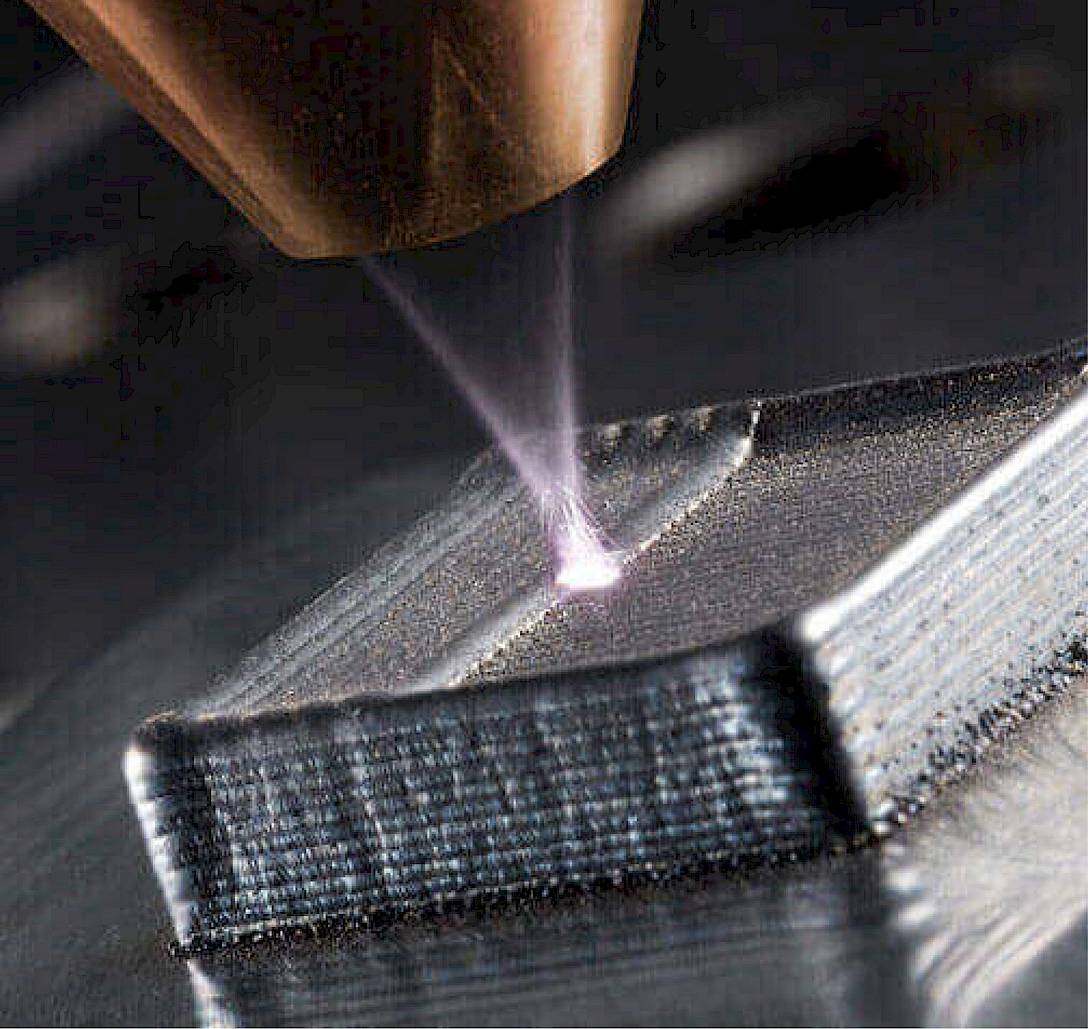

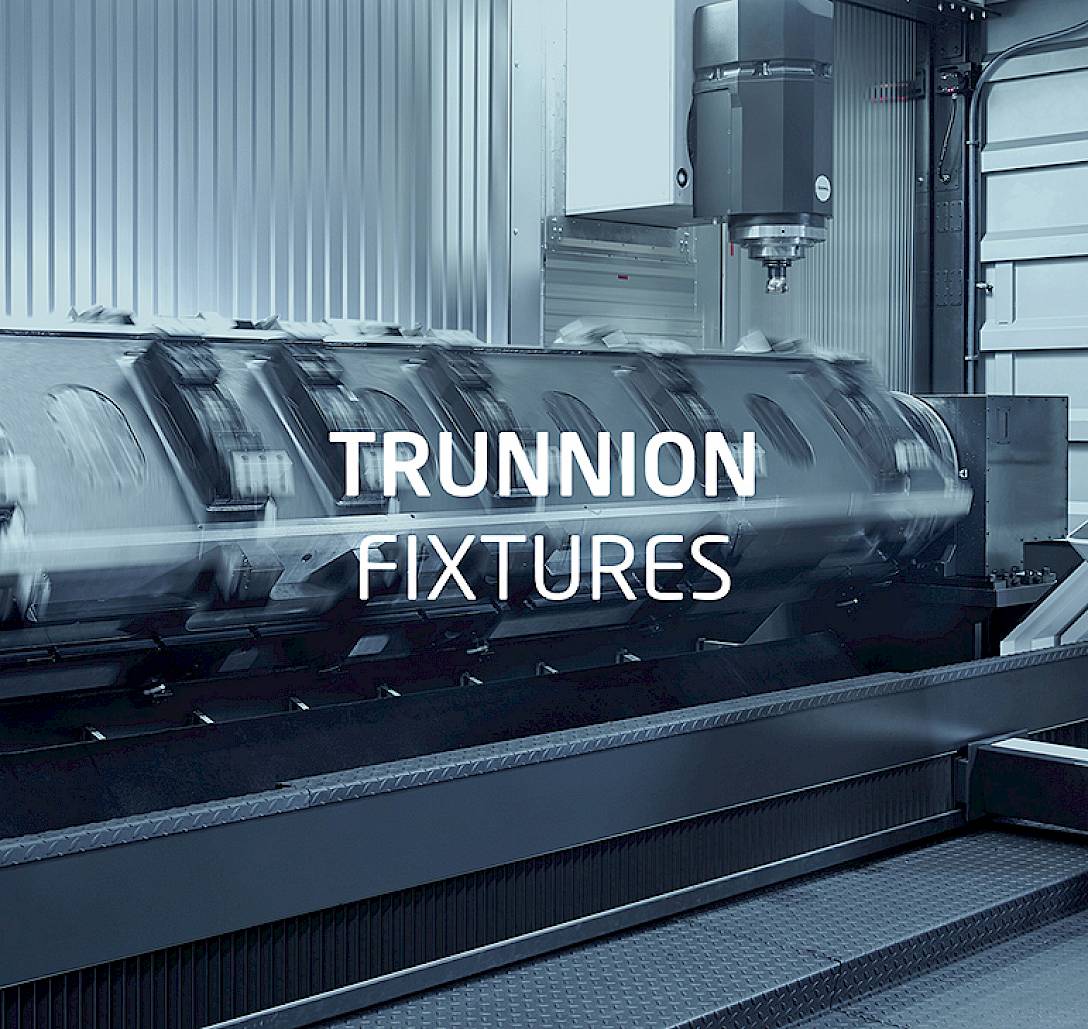

CONFLES: new manufacturing and automation technologies for a controlled, flexible, efficient and sustainable process applied to the machining of high-performance materials, with prominent application in complex components (e.g., aeronautics).

GEOMAK: development of a new generation of machine tools with geothermal temperature control systems, improving energy efficiency and thermal stability of the process.

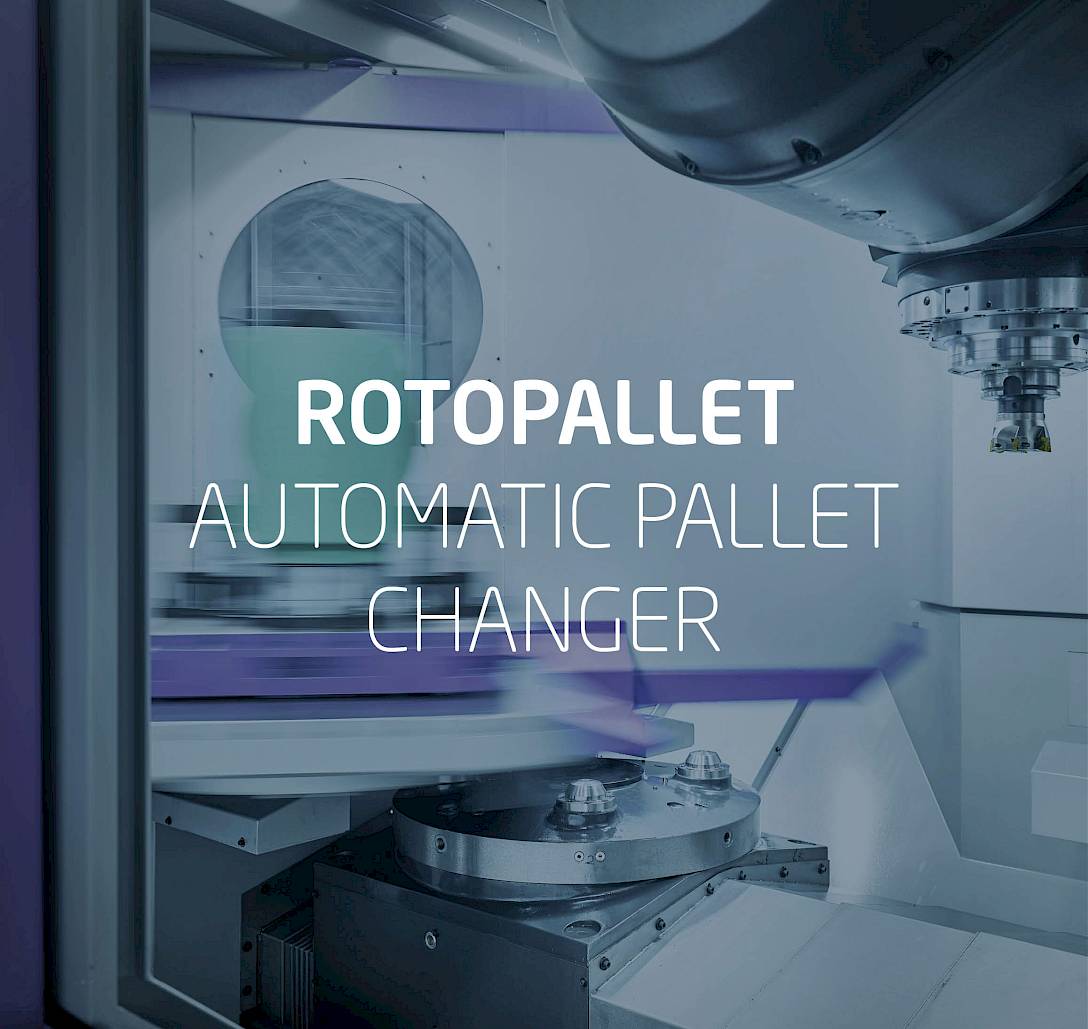

PILGRIM: implementation of an intelligent and interconnected system to optimize the physical load and management of industrial resources.

SKIVING: innovation in gear manufacturing through skiving in machining centers (with additional support from CDTI), aimed at increasing productivity and precision in high-value operations.

PROVERSE: creation of a "process metaverse" to virtualize part and machining, integrating simulation and advanced digital twin approaches to anticipate and optimize results.

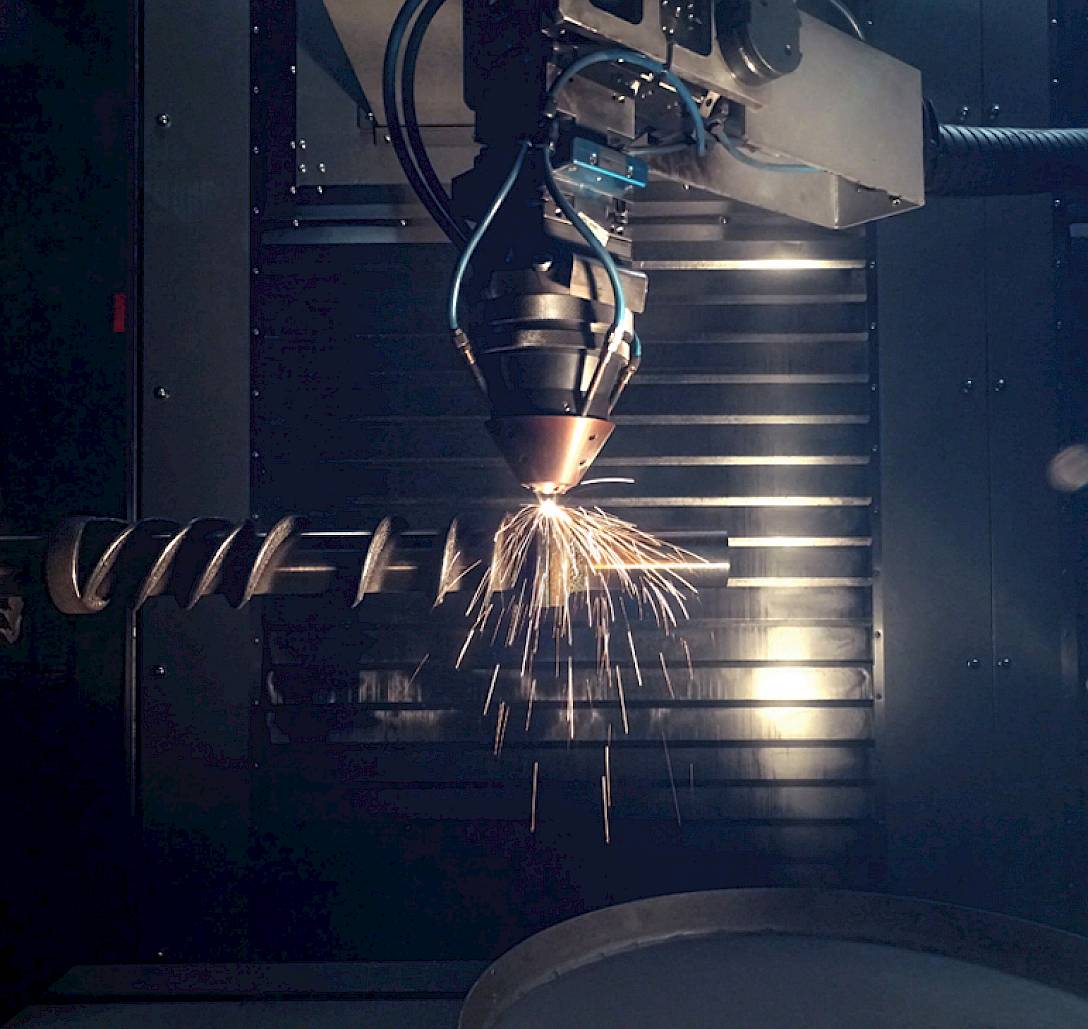

MIKROMAK: research into "micro" technologies to enable a new generation of machines and processes capable of manufacturing micro-level details in macro environments, pushing the boundaries of precision and capability.

PROFECIA (ProfecIA): development and application of artificial intelligence technologies to provide the means of production with greater autonomy, semi-autonomous operation and assistance to the operator when his intervention is critical.

These projects reinforce IBARMIA's commitment to applied research and industrial transfer, promoting more precise, automated and digital solutions for current and future manufacturing challenges.

01