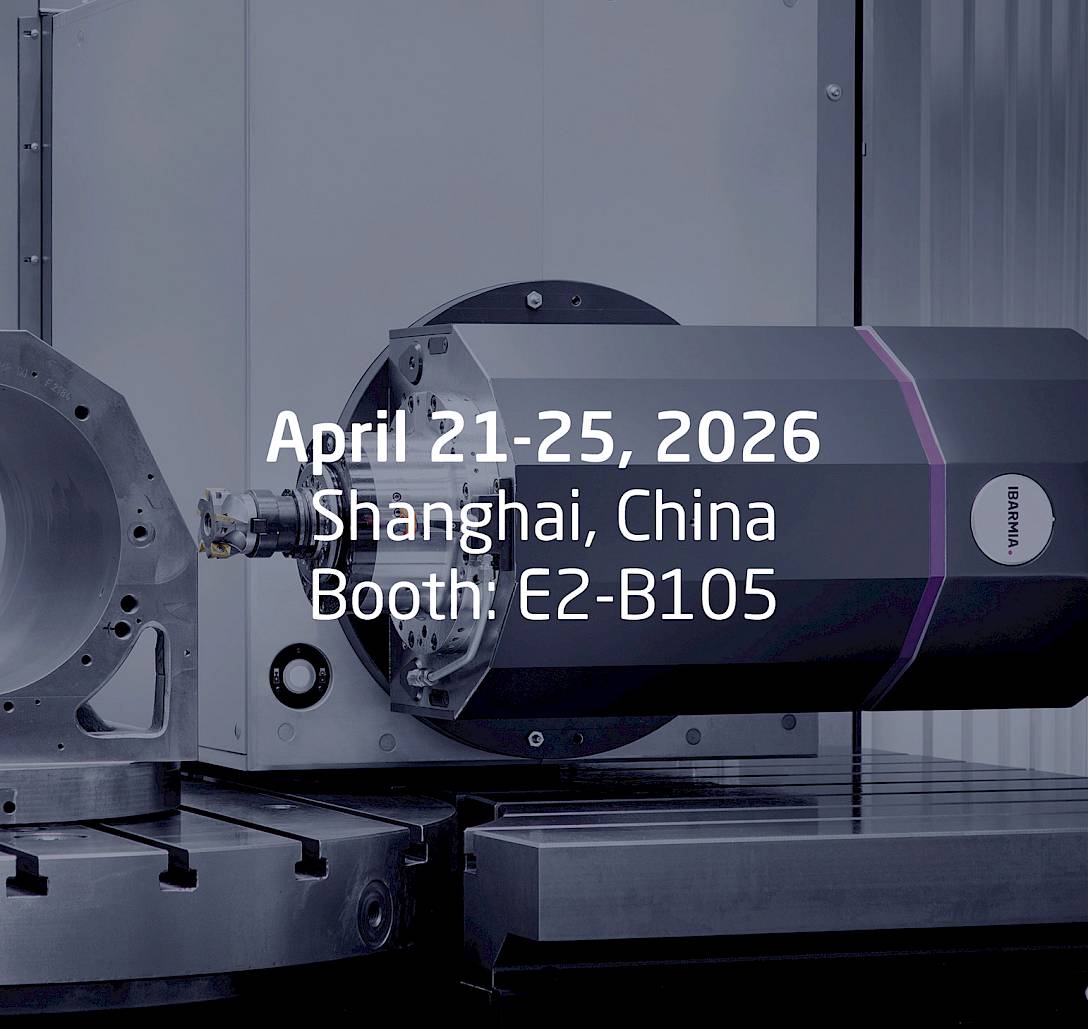

A tailor-made solution for integrated machining and unattended production in ABC’s Eibar plant

New

ABC COMPRESSORS BOOSTS PRODUCTIVITY WITH THC 16 MULTIPROCESS AND PALLET POOL SOLUTION

ABC COMPRESSORS, with over 80 years of history and operations in more than 120 countries, continues to strengthen its leadership in the field of piston compressors. Committed to innovation and customer-focused solutions, the company has taken a major step forward by incorporating IBARMIA’s advanced MULTIPROCESS technology into its production plant in Eibar, Spain.

THE CHALLENGE: FLEXIBILITY, INTEGRATION AND AUTONOMY

In response to increasing demands for smaller batch sizes and shorter lead times, ABC COMPRESSORS sought a solution that could integrate turning, milling, and drilling operations into a single, fully automated unit. The primary goal: reduce handling and setup operations, enhance machining efficiency, and transition toward autonomous production — specifically enabling 3-shift operation with one shift completely unattended.

Following a thorough evaluation of available technologies, ABC’s technical team selected IBARMIA’s THC 16 MULTIPROCESS with pallet pool as the most complete and future-ready solution.

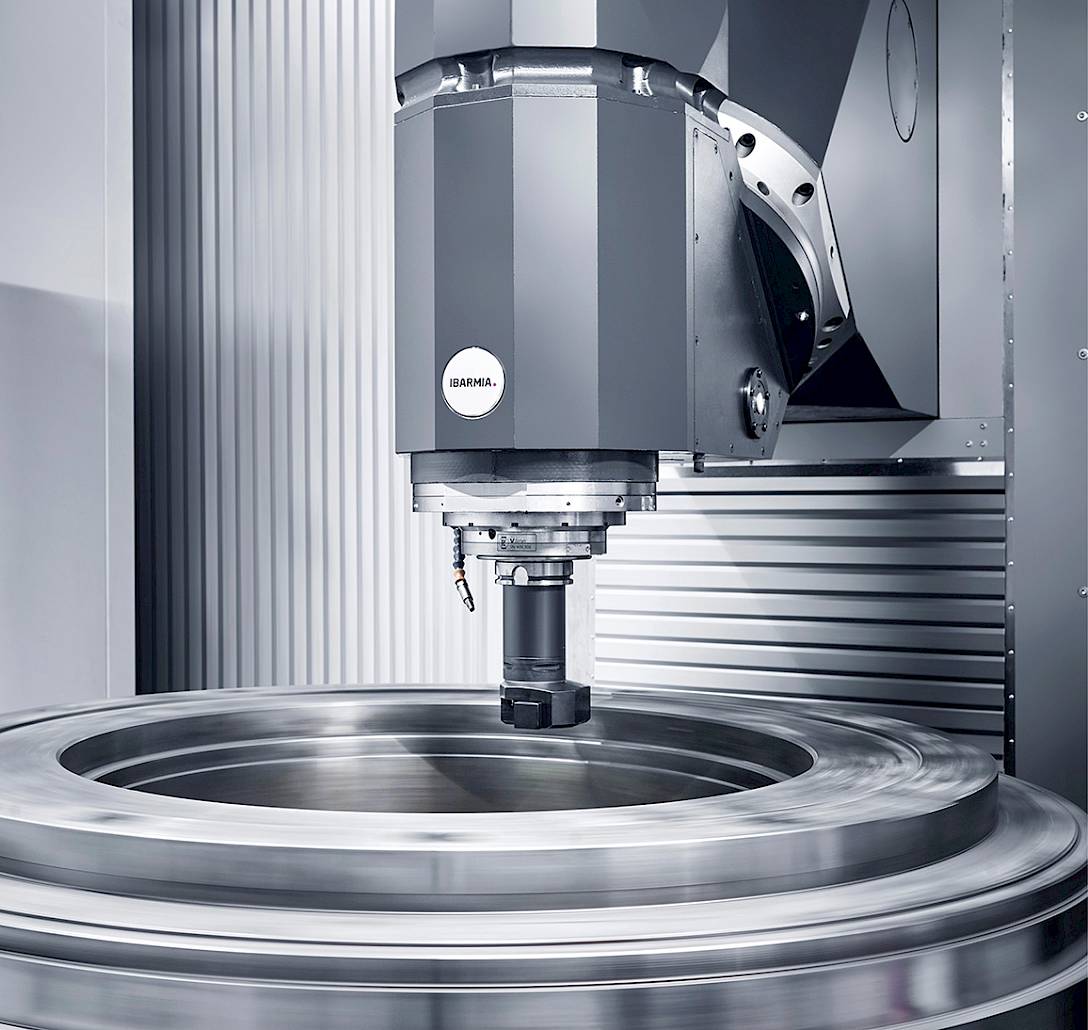

THE SOLUTION: TAILOR-MADE MULTIPROCESS TECHNOLOGY

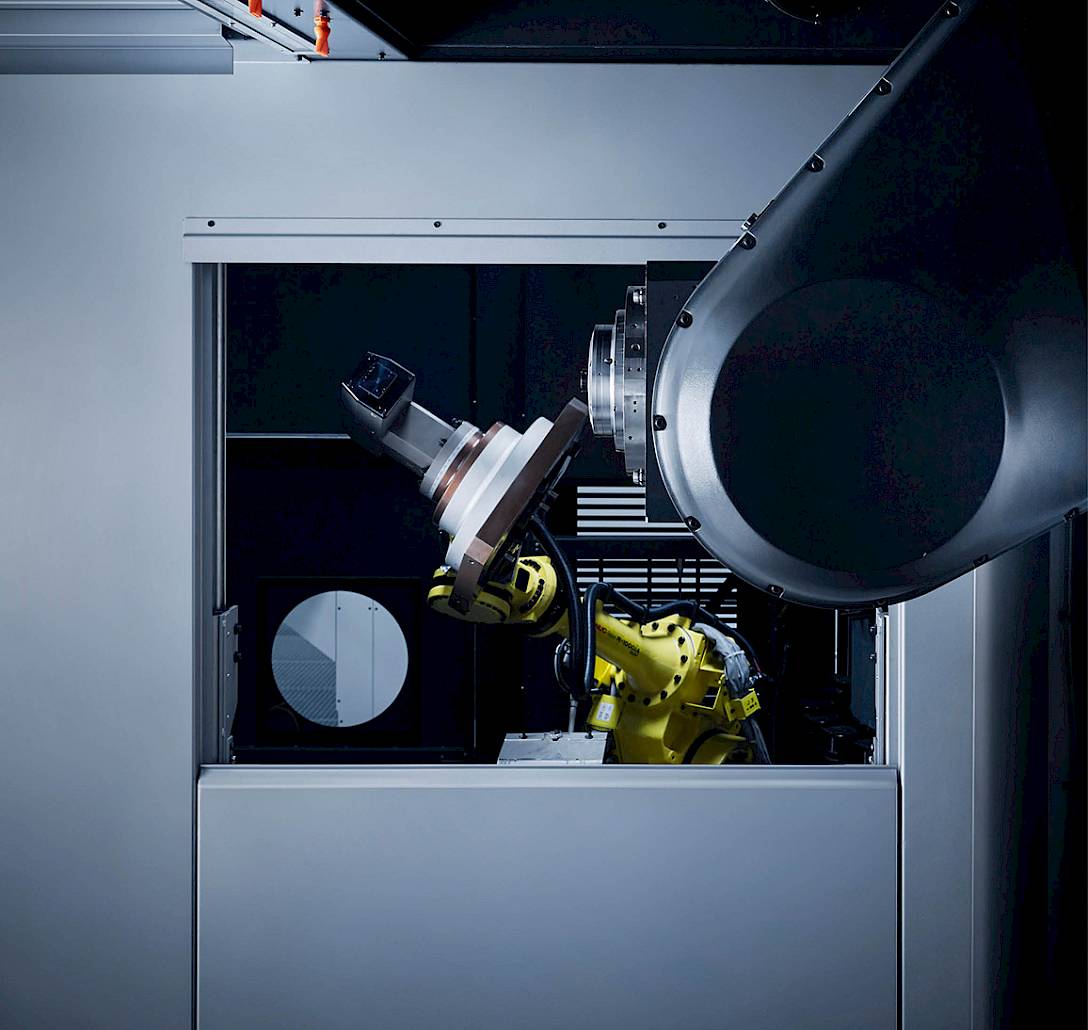

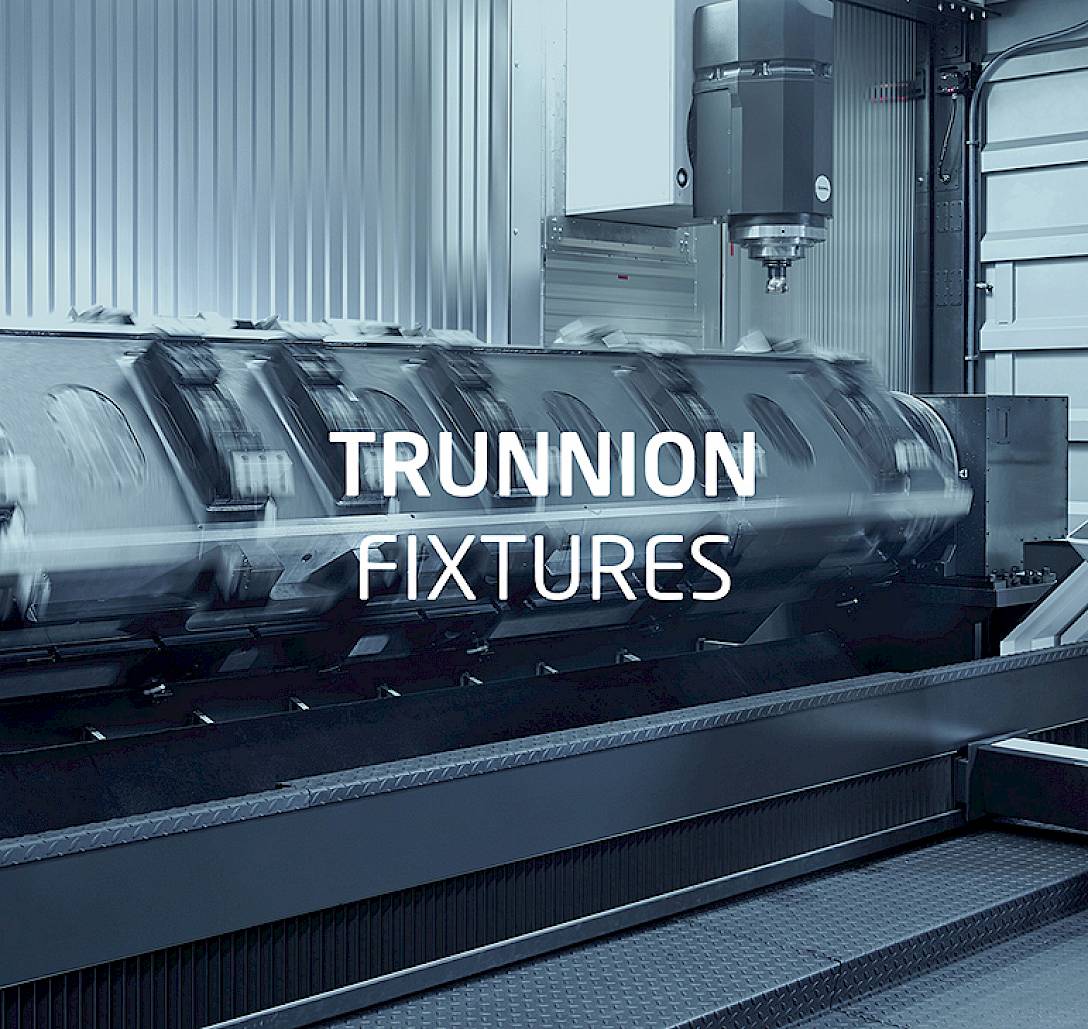

The chosen machine is part of IBARMIA’s T Series, a range designed for high-complexity operations requiring multiple turnings and 5-axis machining in a single setup. It features a rotary transfer table and travelling column, providing maximum flexibility and accessibility — two essential features for ABC’s machining needs.

Key benefits of the solution include:

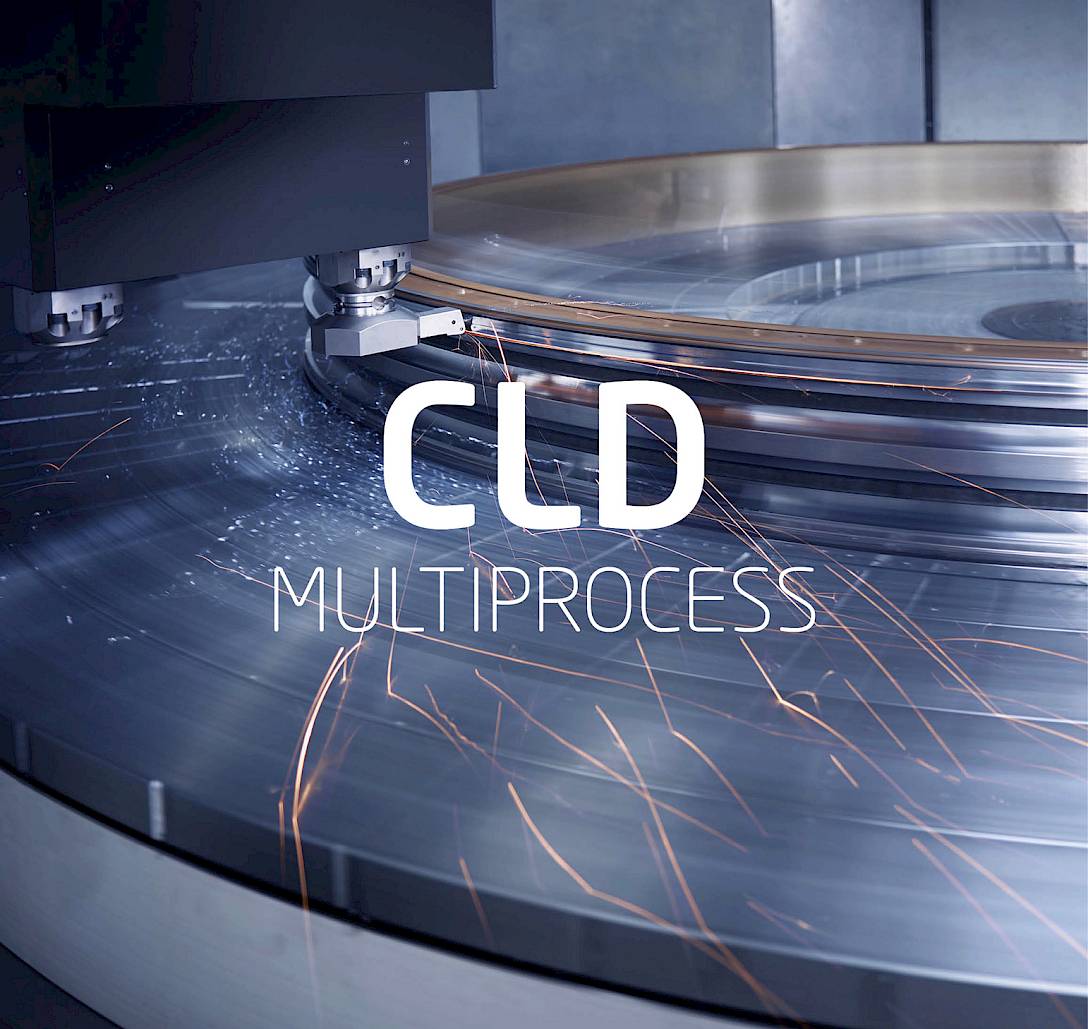

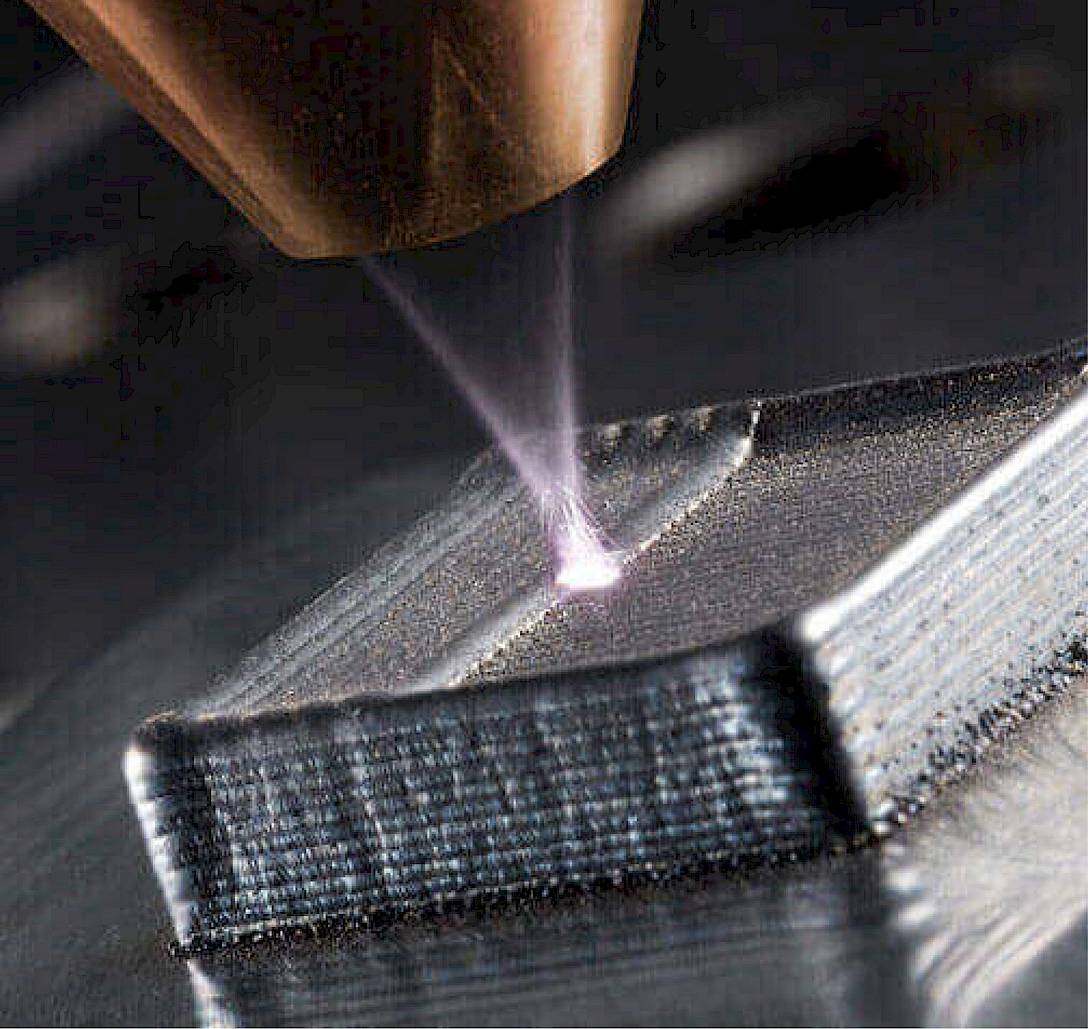

MULTIPROCESS TECHNOLOGY

IBARMIA’s MULTIPROCESS concept allows multiple operations to be combined into one machine, significantly reducing machining time and the number of setups. This leads to better part quality, a smaller footprint on the shop floor, and a more streamlined production flow — all critical for manufacturers focused on efficiency and precision.

UNATTENDED OPERATION VIA PALLET POOL

The system is equipped with a pallet pool, allowing for extended autonomous operation and enabling high machine utilisation, even during unmanned shifts. This not only reduces response times to customer demands but also accelerates return on investment by maximizing productive hours.

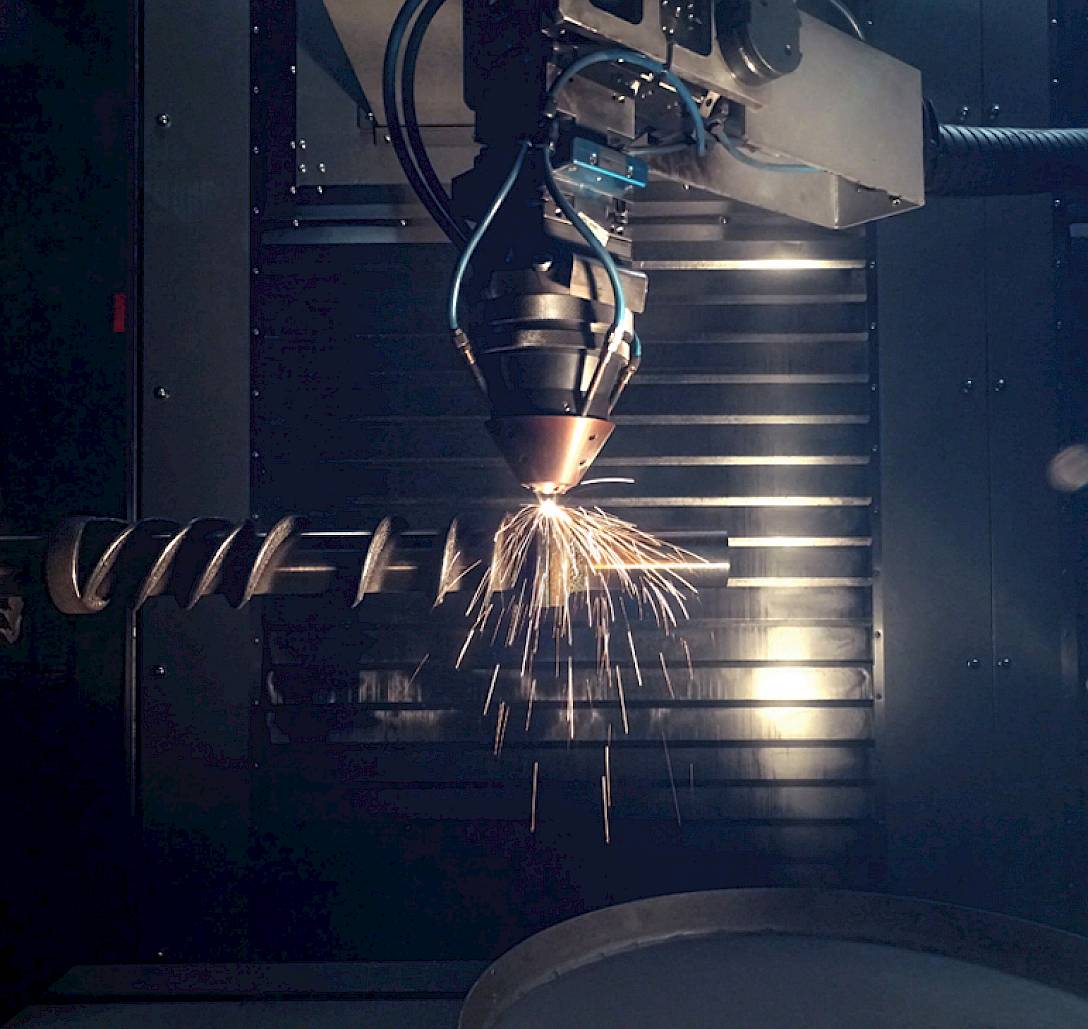

ADVANCED TOOL AND HEAD MANAGEMENT

A robotised magazine with up to 450 stations for HSK100 or CAPTO C6 tools ensures full traceability and minimises setup time. Tools and heavy heads are automatically exchanged using a dual-grip robotic arm. The integration of sensors and microchips allows real-time monitoring of tool wear, breakage, and status, reducing errors and improving operational reliability.

SMART POINT: CONNECTED INTELLIGENCE

The machine is equipped with SMART POINT, IBARMIA’s digital platform for capturing and analysing key production data. It enables smart monitoring of machining operations, tool usage, and part management, supporting data-driven decision making and process optimisation.

A MODEL COLLABORATION

From early planning through to installation, the collaboration between ABC COMPRESSORS and IBARMIA was marked by close cooperation and shared technical insight. Project managers Gaizka Oyarbide, Aitor Larruskain and Aiert Gurrutxaga from ABC highlight the smooth execution and adaptability of the process.

“The installation was completed efficiently, and we adapted to evolving needs with minimal impact. We especially appreciated the accessibility and support from every IBARMIA team — commercial, engineering, mechanical, and electrical.”

LOOKING TO THE FUTURE

With the THC 16 MULTIPROCESS and pallet pool now in operation, ABC COMPRESSORS enhances its competitiveness with more agile, efficient and autonomous machining capabilities. The solution supports the company’s global vision and its ongoing pursuit of excellence in compressor manufacturing.

“We look forward to continuing our collaboration with IBARMIA, especially in programming new references. Their expertise has been instrumental in achieving our goals — and will remain so as we move ahead.”

Interested in improving productivity and safety in your machining processes?

Discover how our solutions can transform your production.

COCTACT

COCTACT

Interested in improving productivity and safety in your machining processes?

Contact IBARMIA today to discover how our solutions can transform your production.

CONTACT US

Interested in improving the productivity and safety of your machining processes?

Contact IBARMIA to discover how our solutions can transform your production.

01